In this new technological dispensation, innovation has completely changed how brands and businesses work. For you to thrive in business, you must ensure you evolve around digital innovation. You also need to scale your internal venture-like environments and offer new and advanced products and services to your customers.

The traditional, now outdated discoveries and development strategies are going through a shift that requires new manufacturing technologies that support sustained competitiveness. Today, startups are not the leaders in implementing the latest technologies as they used to be back in the day. Established businesses are quickly adopting modern methodologies in software development and design, like prototyping. Today, established firms are quickly translating innovative startup processes into their corporate structure. Going forward, we believe that they will capitalize on the startup’s untapped digital opportunities, such as rapid prototyping in manufacturing, material and processes, product design, and technologies, as well as the rapid development of innovative products and accelerated innovation.

What is Rapid Prototyping?

Prototyping is the process of validating the possibility that a product will be capable of solving the problem that is required. A prototype seems to be real enough such that potential users can interact with it and give feedback. In case the feedback given by the user about the prototype is negative, the firm saves considerable amounts of time and money to build a product or service that won’t perform in a real sense. Positive feedback, on the other hand, shows that the product concept is on point and, from there, aids in advanced product development.

The term rapid, on the other hand, is used to mean the speed in which the prototype can be produced. Also, how fast the feedback can be collected and synthesized and also, how quickly the following iterations can go through the same process. Therefore, there is a great need for teams to strike a balance between creating a prototype that looks near-real so that users can provide real feedback and reactions.

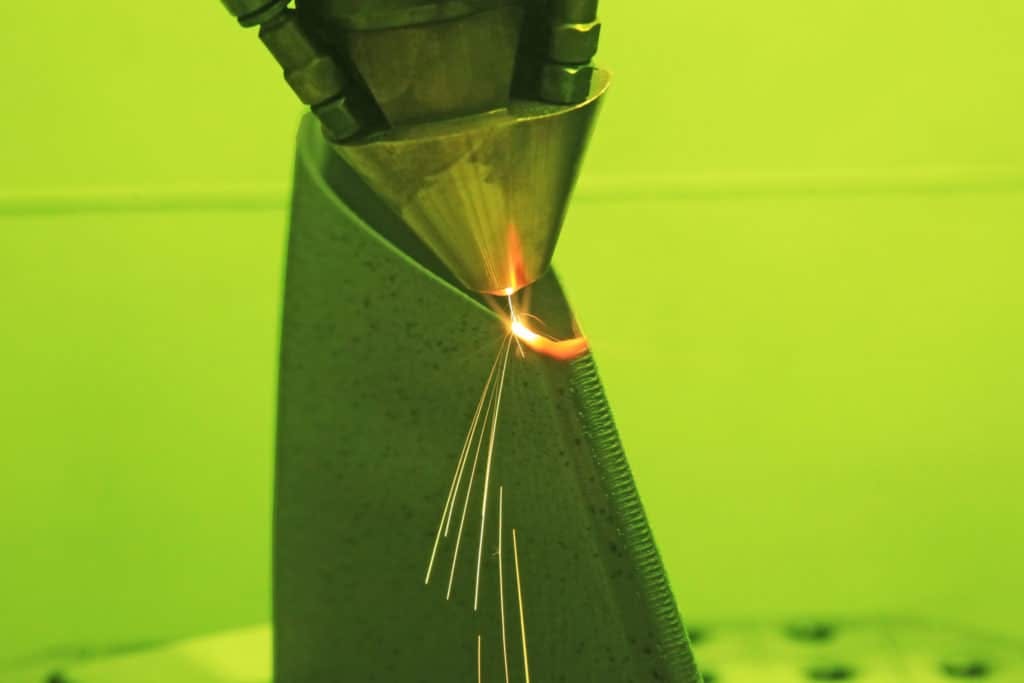

DMLS – Direct Metal Laser Sintering

The technology is useful in most industries today and has a wide range of applications, including the automotive industry, marine, aerospace and defence, robotics, energy, and consumer products.

Types of Prototypes in Product Design

Prototypes are categorized based on the degree of accuracy needed. For instance, there is Fidelity. Also, they can be classified depending on the product development stage the technology is applied.

Fidelity types

Prototypes don’t have to look exactly like the final product and can vary widely based on what the designer wants to achieve from it. As stated, rapid prototypes are classified based on the accuracy needed. The degree of accuracy varies from low to high Fidelity in the product's appearance, functionality, size, and user interface.

Low Fidelity Prototype

These are very simple, and they are produced very quickly to test the boarder concept, such as cardboard mock-ups and paper sketches or consumer products.

High Fidelity prototypes

These appear and work exactly like the final product. They are used in industries where unmatched precision is required, and the best use of 3D printing is of the essence, e.g., in the automotive, robotics, aerospace and defence industries since the production parts are cut precisely.

Selective Laser Sintering

Selective laser sintering (SLS) is an AM technique (additive technology) with the lasers the power source for sintering powdered materials such as polyamide or nylon. It aims the laser automatically at the points in space that are defined by a 3D model.

What are the benefits of using Rapid prototyping in Product design and development?

It is one of the challenges that most product designers face, being unable to make in-house management stuff or have their clients realize how the end product will look and feel. While today, there are tremendous advancements in 3D and CAD technologies, it is still a daunting task to explain the design aspects through digital models. Therefore, one must prove it first.

Rapid prototyping and manufacturing technology has come a long way, and today, it's gaining popularity among manufacturers and engineering designers. It remains to be a fast and accurate way of realizing the potential of a product. This is why firms no longer shy away from adopting rapid prototyping technologies when developing their new products. It brings a high fidelity from the conceptualized product when you judge against the conventional paper prototyping. Here are some of the benefits of this technology in product design and development.

Realise the design concept

This technology allows one to realise the concepts beyond just virtual visualisation, thus making one understand the looks and feel of a design. Therefore designers can forward their ideas and apply them in the design before finalisation. The end client who won’t take anything short of realistic product design is also provided with a proof of concept

Incorporates changes instantly

With a physical model ready, you can easily incorporate changes immediately by asking your customers for feedback. There are lots of iterations needed before you finalise the design. With every iterative process, the design is further improved, and this builds confidence among the designer and consumer.

Saves costs and time

Rapid prototyping service in manufacturing is cost-effective and reduces the time spent in developing patterns and moulds and also eliminates the cost of bringing in specialised tools. You will use the same printing equipment and CAD software to produce various geometries. There is less materials that goes to waste as selective laser melting is pretty much used.

In conventional paper prototyping, eg, CNC machining, the waste produced is significant, compared to rapid prototyping where it only prints only the material that’s needed to build a project.

Minimises design flaws

Additive manufacturing enables one to identify defects in the design before mass production. Materials used in additive manufacturing pretty much look like the properties and strength of the real product. This it is possible to execute a physical test easily. Faults and usability will be identified earlier, avoiding risks that may manifest later in the manufacturing process.