Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

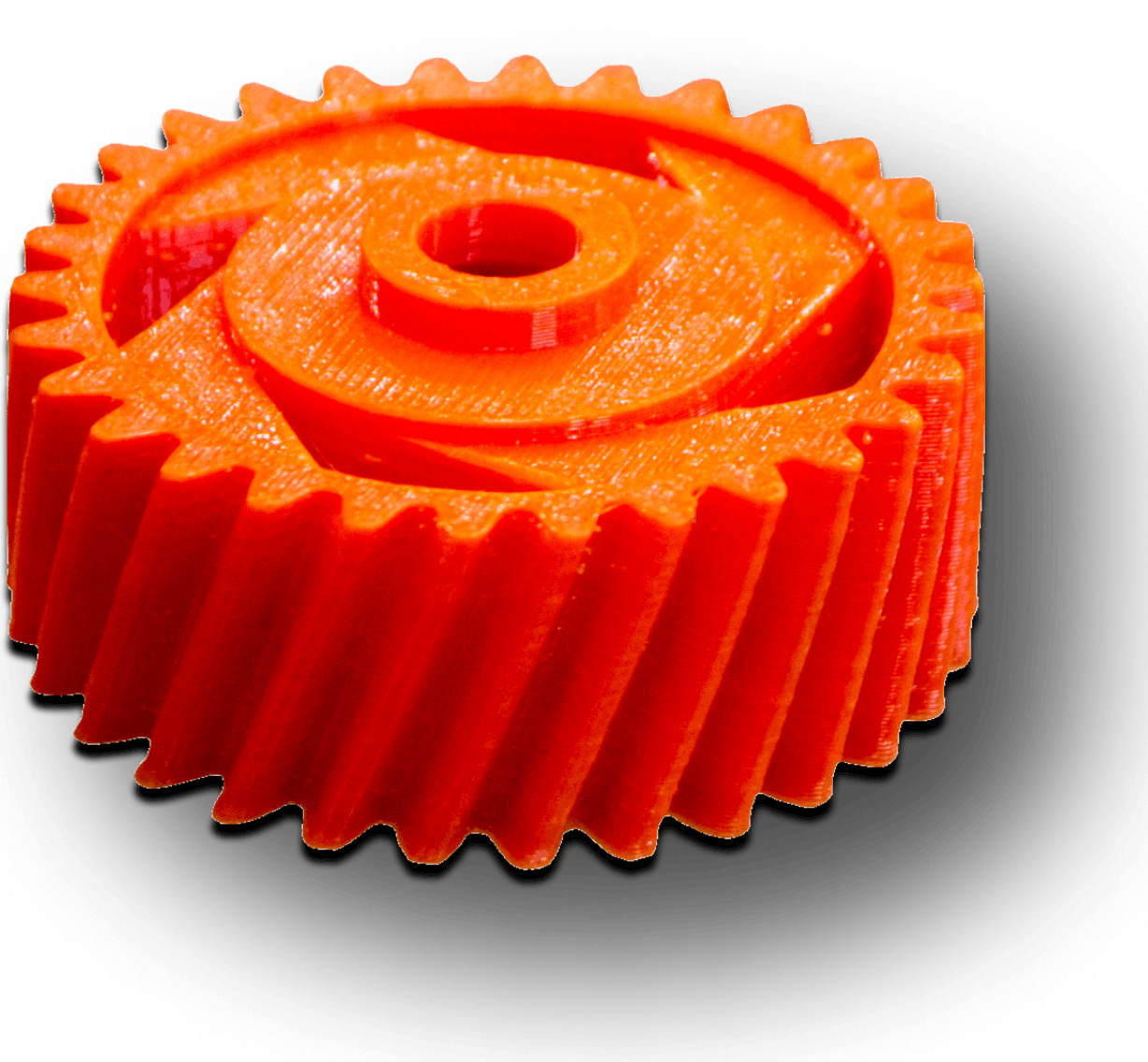

Get durable FDM 3D printed parts from prototyping materials and industrial-grade plastics, ideal for functional prototypes and end-use applications. With robust quality control and a range of durable materials, our FDM process ensures reliable, high-quality parts the first time, every time.

All uploads are secure and confidential.

Trusted by

Fused Deposition Modelling (FDM) is a 3D printing technology widely known for its availability, ability to print large parts, and affordability. FDM is also highly versatile, supporting a wide range of materials, from standard ABS and PLA to speciality polymers like nylon and carbon fibre composites. Fused deposition modelling 3D printing machines produce parts by extruding thermoplastic filament layer by layer onto a build plate. FDM 3D printed parts are great for end-use, low-volume production, and rapid prototyping.

At Geomiq, we’re proud to partner with 260+ experienced and highly vetted fused deposition modelling service providers with a proven track record of making high-quality, durable FDM 3D printed parts for customers all over the globe. With our partners’ expertise, access to 120+ of the latest FDM 3D printers, our engineers’ attention to detail, and our entire team’s commitment to exceptional quality assurance at every stage, you can rest assured that with Geomiq, you’ll receive only the best FDM 3D printed parts – the first time, every time.

Tolerances

Standard: ± 0.5% with a lower limit of ± 0.5 mm

Industrial: ± 0.3% with a lower limit of ± 0.3 mm

Layer height

Economy: 0.3 mm

Standard: 0.2 mm

Fine: 0.1 mm

Max. build size

Standard: 500 x 500 x 500 mm

Industrial: 900 x 600 x 900 mm

Min. feature size

0.5 mm

Standard lead time

From three days business days

Tolerances | Layer height | Max. build size | Min. feature size | Standard lead time |

|---|---|---|---|---|

Standard: ± 0.5% with a lower limit of ± 0.5 mm | Economy: 0.3 mm | Standard: 500 x 500 x 500 mm | 0.5 mm | From three days business days |

Standard: 0.2 mm | ||||

Industrial: ± 0.3% with a lower limit of ± 0.3 mm | Fine: 0.1 mm | Industrial: 900 x 600 x 900 mm |

Our streamlined order process allows you to receive a quote instantly or in under one business day, and FDM 3D printed parts are delivered in as little as three working days.

All of our partners’ Fused deposition modelling 3D printing technologies are the most up-to-date in the industry, ensuring that you always benefit from the latest innovations in selected laser sintering services

With our network of over 260 manufacturers offering FDM 3D printing services, you can rest assured that there is always capacity for both prototyping and large-scale production.

Our FDM printing services create parts that meet the high-quality demands of numerous industries, from mission-critical aerospace parts to medical components.

Geomiq’s FDM 3D printing services provide industrial-grade, high-quality engineering material options, ensuring you have the perfect material for your application.

Upload your CAD model to our platform, select your lead time, and get an instant or 24-hour FDM 3D printing quote.

We select the most suited manufacturer for your order, with production starting immediately.

We guarantee your order arrives to specification with our industry-leading virtual and physical quality standards.

We ship your parts on express services where possible, providing physical delivery notes and inspection reports.

Upload your CAD model to our platform, select your lead time, and get an instant or 24-hour FDM 3D printing quote.

We select the most suited manufacturer for your order, with production starting immediately.

We guarantee your order arrives to specification with our industry-leading virtual and physical quality standards.

We ship your parts on express services where possible, providing physical delivery notes and inspection reports.

We’re committed to providing the best quality assurance in the business. Our highly skilled engineers triple-check all of your files and parts from the initial FDM 3D printing service quote to the final inspection – ensuring that you’re happy with your results the first time, every time.

At Geomiq, we understand the value of time in your product development, and the speed of our FDM 3D printing service reflects this. When you upload your files, we provide you with a quote instantly or within one business day. Our network of highly experienced partners ensures you receive your parts in as little time as possible.

We partner with 260+ highly vetted and experienced manufacturers from 50+ countries so that you can benefit from more options, greater capabilities, and the highest standards in the world. With our FDM printing service, you can rest assured that there’s always capacity to handle your project.

All uploads are secure and confidential.

Support structures, if present, will be removed, and support surface nibs will be lightly sanded until smooth. Parts will have a visibly layered surface with fine layer lines.

Parts are placed in a chamber with solvent vapour, which condenses to soften and even out layer lines. As it evaporates, a glossy, sealed finish forms, reducing surface roughness and enhancing appearance.

Parts are sanded and primed to enhance adhesion. The part is then spray painted the desired colour. This process not only enhances the part’s visual appeal but also provides a functional layer of protection against environmental factors like moisture and UV exposure.

You can specify custom finishes such as epoxy coating and electroplating. Note that custom finishes require manual review and quoting and may be subject to approval.

Benefits:

Limitations:

FDM

Standard: ± 0.5% with a lower limit on ± 0.5 mm

Industrial: ± 0.3% with a lower limit of ± 0.3 mm

MJF

± 0.3% with a lower limit on ± 0.3 mm

SLS

± 0.3% with a lower limit of ± 0.3 mm

SLA

Standard: ± 0.3% with a lower limit of ± 0.3 mm

Industrial: ± 0.2% with a lower limit of ± 0.13 mm

DMLS

±0.2% with a lower limit on (0.1 – 0.2 mm)

FDM

Low cost, wide range of materials

MJF

Design flexibility, support not required

SLS

Design flexibility, support not required

SLA

Smooth surface finish, fine feature details

DMLS

Engineering-grade metals, numerous post-processing options, complex geometries

FDM

Standard: 500 x 500 x 500 mm

Industrial: 900 x 600 x 900 mm

MJF

380 x 285 x 380 mm

SLS

395 x 500 x 395 mm

SLA

Standard: 145 × 145 × 175 mm

Industrial: 500 x 500 x 500 mm

DMLS

400 x 400 x 400 mm

FDM

100-300μm

MJF

80μm

SLS

100μm

SLA

25-150μm

DMLS

20 – 80 mm depending on the material

FDM

2.0 mm

MJF

0.5 mm

SLS

0.762 mm

SLA

0.2 mm

DMLS

0.5 mm

Dimensional accuracy | Strengths | Build volume | Layer thickness | Min. feature size | |

|---|---|---|---|---|---|

FDM | Standard: ± 0.5% with a lower limit on ± 0.5 mm Industrial: ± 0.3% with a lower limit of ± 0.3 mm | Low cost, wide range of materials | Standard: 500 x 500 x 500 mm | 100-300μm | 2.0 mm |

MJF | ± 0.3% with a lower limit on ± 0.3 mm | Design flexibility, support not required | 380 x 285 x 380 mm | 80μm | 0.5 mm |

SLS | ± 0.3% with a lower limit of ± 0.3 mm | Design flexibility, support not required | 395 x 500 x 395 mm | 100μm | 0.762 mm |

SLA | Standard: ± 0.3% with a lower limit of ± 0.3 mm Industrial: ± 0.2% with a lower limit of ± 0.13 mm | Smooth surface finish, fine feature details | Standard: 145 × 145 × 175 mm | 25-150μm | 0.2 mm |

DMLS | ±0.2% with a lower limit on (0.1 – 0.2 mm) | Engineering-grade metals, numerous post-processing options, complex geometries | 400 x 400 x 400 mm | 20 – 80 mm depending on the material | 0.5 mm |

All uploads are secure and confidential.

We have hundreds of global manufacturing partners offering fused deposition modelling services. These ensure we offer competitive pricing and have unlimited capacity. We can route jobs geographically to reduce lead times and shipping costs, as well as reduce the carbon footprint of each order. All of our MJF 3D printing partners have stringent onboarding, and we use data to track on-time deliveries, quality and pricing. This ensures that your job and MJF 3D printing parts are always with the most suited supplier.

See our case studies in action. Discover how we turn ideas into products with our prototyping and manufacturing capabilities.

Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Jamie Fairclough

Design Lead

Industrial Robotics | Arrival

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

James Batstone

Future Product Research Lead

Brompton Bikes

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

Alex Leck

Design Engineer

JCL Lighting

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

All uploads are secure and confidential.