CNC Machining Guide

Curious about CNC machining? Our easy guide breaks down the process, real-world uses, pros, and cons, so you can make smarter project decisions.

What is CNC Machining?

From aerospace and automotive components to life-saving medical implants and everyday tech like smartphones, CNC machining is behind much of the innovation we rely on. But what is CNC machining exactly?

CNC machining is a subtractive manufacturing process. It creates parts by removing material from a solid block or sheet using computer-controlled tools. This precision-driven process supports everything from rapid prototyping to mass production across countless industries.

What Does CNC Mean?

CNC stands for Computer Numerical Control. It refers to the use of computers to automate the control of machine tools like mills, lathes, drills, and cutters.

In a CNC system, engineers create a 3D CAD model of the part. This design is then converted into G-code via CAM software. G-code is a machine-readable language that includes instructions like:

- Tool movement and direction

- Cutting speed and depth

- Feed rate

- Start/stop actions

The CNC machine’s controller reads this code and sends precise electrical signals to motors and actuators, guiding the cutting tools exactly as needed.

CNC technology brings speed, consistency, and repeatability to manufacturing-especially for complex or intricate parts.

How CNC Machining Works

Whether you're manufacturing a prototype or a large production run, CNC machining generally follows five core steps:

Step 1: Create a 3D CAD Model

Designers build a 3D model using Computer-Aided Design (CAD) software. This model defines dimensions, tolerances, and other part features. This is also where Design For Manufacturing (DFM) principles come ensuring your design is optimised for cost-effective machining.

Step 2: Convert CAD to G-code

Using CAM software, the CAD file is converted to G-code, which contains all toolpaths and machining parameters.

Step 3: Prepare the Machine and Workpiece

Operators secure the material to the machine bed and insert the appropriate cutting tools. Tool offsets, fluid systems, and other settings are configured.

Step 4: Execute the Machining Operation

The CNC machine follows the G-code instructions to cut away material and shape the part. Some jobs may require manual tool changes or repositioning.

Step 5: Post-Processing

Depending on the application, parts may be bead blasted, anodised, powder-coated, or polished for enhanced functionality or appearance. Explore options like bead blasting, anodising, and powder coating in our CNC machining surface finish gallery.

Watch this short video for a visual explanation of how CNC machining works from design to production

CNC Machining vs. Other Manufacturing Methods

CNC machining is one of the most widely used manufacturing methods in the UK particularly valued for its precision, repeatability, and speed. But how does it compare to other technologies like 3D printing or injection moulding?

In the UK manufacturing sector, CNC machining is often the go-to choice when accuracy and material performance are non-negotiable, as in aerospace engineering, medical prototyping, or precision components for industrial machinery.

While additive manufacturing offers more design freedom, CNC machining is often faster for fully functional parts and delivers better mechanical properties, especially in metals.

Types of CNC Machining

CNC machining is not a one-size-fits-all approach. Several types of operations exist, each suited for different shapes, tolerances, and materials.

CNC Milling

The most common form of CNC machining. A rotating cutting tool removes material from a stationary block. CNC mills can cut flat surfaces, slots, holes, and complex 3D shapes.

- 3-axis CNC milling: Movement on the X, Y, and Z axes

- 5-axis CNC milling: Adds rotation to either the tool or workpiece, enabling complex, multi-sided cuts in one setup

Geomiq offers a professional CNC milling service for both prototype and production parts, with capabilities spanning 3-axis to full 5-axis machining.

For an in-depth look at techniques, machines, and tips, explore our complete CNC milling guide.

CNC Turning

In this process, the workpiece rotates while a stationary cutting tool shapes it. Turning is ideal for cylindrical parts, like shafts, pins, and bushings.

Key turning operations include:

- Straight turning

- Taper turning

- Facing

- Grooving

Machines used: CNC lathes and turning centres (some with milling features).

For details on tools, machines, and use cases, see our full guide on CNC turning.

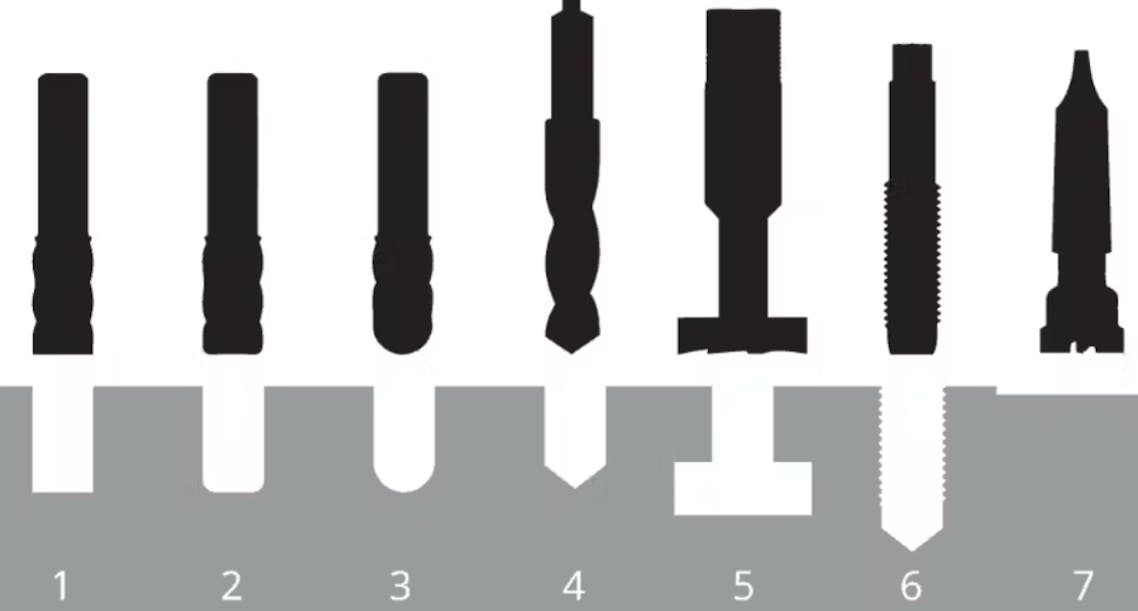

CNC Drilling

Drilling machines use rotating drill bits to make precise holes. CNC mills can also drill, but dedicated CNC drills offer better speed and efficiency for high-volume hole making.

These machines often use a gantry x-y motion system to move the cutting head efficiently across large flat workpieces.

Common applications:

- Holes for fasteners

- Tapping and threading

- Boring and countersinking

CNC Routing

Used for lightweight materials like wood, plastic, and foam. Routing is a surface-level operation ideal for signage, patterns, and engraved parts.

Routers prioritize speed and precision over torque and often include:

- Gantry-style design for large, flat sheets

- Light-duty cutting heads

- 2.5D or limited 3D capability

CNC Cutting

“Cutting” typically refers to slicing flat sheets using high-energy or high-speed media. It’s common in sheet metal fabrication and works well for 2D parts.

Types of CNC cutting:

- Laser cutting: Uses a focused laser to melt or vaporize material.

- Waterjet cutting: High-pressure water (with or without abrasives) slices through various materials. Geomiq’s waterjet cutting service supports a wide range of materials and produces clean edges with no heat-affected zones.

- Plasma cutting: Electrically conductive plasma arc melts through metal.

CNC cutting is widely used in sheet metal fabrication for applications such as enclosures, brackets, and panels.

Electrical Discharge Machining (EDM)

EDM uses electrical sparks to erode material from a workpiece, especially hard metals. The part and tool are submerged in a dielectric fluid that cools the area and removes debris.

Use EDM for:

- Intricate geometries

- Heat-sensitive materials

- Tooling and mould making

For technical insights, visit our full breakdown of Electrical Discharge Machining.

Designing For CNC Machining

Good design is the foundation of successful CNC machining. Optimising for manufacturability ensures you get high-quality parts, faster turnaround times, and lower costs.

Key Design Considerations

Tolerances define how much a part’s actual measurement can deviate from the design without affecting its function. Standard tolerances for CNC machining are:

- Milling (3-axis / 5-axis): ± 0.13 mm (± 0.005″)

- Lathe: ± 0.13 mm

- Engraving: ± 0.13 mm

- Die cutting: ± 0.38 mm

Not sure which tolerances are right for your part? Our machining tolerances guide can help you decide based on function and cost.

Other Geometric Tips:

- Avoid sharp internal corners – Use radii, as most cutting tools are round.

- Limit cavity depth – Should not exceed 6× the tool diameter.

- Watch wall thickness – Thin walls may vibrate or break during cutting.

- Use standard hole sizes – Makes tooling faster and more cost-effective.

- Thread depth – Threads longer than 3× diameter are rarely needed.

For more detailed guidelines, check our CNC design guide.

Essential CNC Software

CNC machining is powered by software at every step - from designing to programming to testing.

CAD (Computer-Aided Design)

Used to create accurate 3D models of the part, including dimensions and tolerances. Common CAD file types: STEP (.stp), IGES (.igs)

CAM (Computer-Aided Manufacturing)

Converts CAD models into G-code - the machine-readable instructions that control speed, toolpaths, and depth of cut. CAM software also allows for toolpath simulation to detect errors before machining begins.

CAE (Computer-Aided Engineering)

Used for simulation and analysis. Engineers use CAE to assess stress points, thermal performance, and material deformation through tools like FEA and CFD.

Key Machining Parameters & Terminology

Understanding key CNC terms helps ensure better outcomes when working with manufacturers.

- Cutting tools: End mills, face mills, drills, taps, and reamers. Choose based on part geometry and material.

- Tool path: The programmed route the tool follows. Defined in CAM software.

- Cutting speed: Spindle rotation (RPM). Higher for soft materials, lower for hard ones.

- Feed rate: Speed at which the tool enters the material.

- Depth of cut: Thickness removed per pass - deeper = faster but riskier.

- Surface finish: Smoothness of the part’s surface. Can be adjusted post-processing.

- Fixtures & jigs: Hold the part in place. Fixtures are more common in CNC machining; jigs are rare due to precision programming.

Materials for CNC Machining

One of the biggest strengths of CNC machining is its compatibility with a wide range of materials - from metals to plastics to composites.

Factors to Consider

- End-use – Mechanical, thermal, and electrical properties matter.

- Work environment – Consider exposure to heat, chemicals, or pressure.

- Availability – More common materials can reduce lead times.

- Machinability – Impacts tool life and cutting time.

- Cost – Balance with performance needs.

Common CNC Machining Metals

Metals are the most used engineering materials, so it is no surprise that they are the most machined. Various types of metals and metal alloys have different properties and applications. The table below details the most common CNC machining metals.

View the full list of compatible metals and plastics in our CNC machining materials catalogue.

Common CNC Machining Plastics

CNC machining can also manufacture products from various rigid plastics. However, it is important to take fume safety precautions when machining plastics, as certain plastics release toxic fumes at very high temperatures. The table below shows the properties and applications of some of the most common CNC machining plastics. See our CNC plastic machining article to learn more.

Learn how to machine ABS, PEEK, PTFE, and more in our detailed CNC plastic machining guide.

CNC Machining Applications

CNC machining is a highly versatile manufacturing process with numerous applications across various industries. CNC machining operations produce various sizes, shapes, and object geometries. These objects may be components of a larger assembly or end-use, standalone parts.

Production Types

- Rapid prototyping – Ideal for functional testing and design validation. CNC is ideal for rapid prototyping, especially when function and fit matter more than visual polish.

- One-off parts – Replacement parts, custom tools, or jigs.

- Batch production – Producing dozens to hundreds of consistent units.

Industry Applications

CNC machining plays a vital role in nearly every major manufacturing sector across the UK. From precision aerospace components to custom consumer goods, CNC processes power product development, refinement, and scaled production.

Here are some industry-specific examples of how CNC machining is used:

Aerospace: Engine parts, ducts, and lightweight components

In aerospace hubs like Bristol and Farnborough, 5-axis CNC milling is frequently used to machine aluminium and titanium components such as turbine casings, cooling ducts, and structural brackets.

These parts must meet strict tolerance requirements and perform under extreme pressure and temperature conditions.

Automotive: Gears, housings, and custom fittings

Automotive manufacturers and suppliers throughout the Midlands use CNC turning and milling to produce precision gears, engine housings, and transmission components.

Rapid CNC prototyping is also a key part of the electric vehicle (EV) development process, helping startups iterate parts before moving into tooling or casting.

Medical: Implants, surgical instruments, prosthetics

In cities like Manchester and London, CNC machining supports the production of custom orthopaedic implants, surgical cutting guides, and complex prosthetic devices.

Titanium and cobalt-chrome parts are milled with micron-level precision based on patient-specific scans, ensuring optimal fit and biocompatibility.

Discover how CNC is revolutionising healthcare in our medical CNC machining spotlight.

Consumer products: Electronics, tools, and furniture hardware

CNC machining is a go-to for design studios and product developers creating high-quality consumer goods.

It’s used to prototype or batch-produce components such as device enclosures, kitchen tools, audio equipment parts, and luxury furniture fittings-especially when a polished or anodised finish is required.

Industrial machinery: Fixtures, housings, mechanical parts

UK manufacturers in energy, food processing, and packaging often rely on CNC machining for the creation of replacement fixtures, housings, and structural frames. CNC allows for fast, reliable turnaround-especially when legacy parts are no longer available from OEMs.

Non-industrial: Art, signage, furniture, and custom design

In creative industries, CNC routers and mills are used to carve custom signage, one-of-a-kind furniture, architectural models, and set pieces. Artists, fabricators, and interior designers frequently turn to CNC for its repeatability, speed, and ability to translate digital concepts into tactile reality.

We’re fully accredited with ISO 9001:2015 and ISO 13485:2016 certifications-critical for producing high-quality medical devices in the UK and beyond.

Advantages and Limitations

Advantages

- Precision & accuracy – Tight tolerances and repeatability

- Speed – Quick turnaround from design to part

- Material versatility – Metals, plastics, wood, foam, more

- Complexity – Capable of intricate geometries

- Scalability – From one part to hundreds

Limitations

- High setup cost – Especially for short runs or complex setups

- Material waste – A subtractive process means scrap is inevitable

- Slower for high-volume production – Not ideal for millions of parts

- Design constraints – Sharp internal corners and thin walls may need redesign

Ready to Start your CNC Project?

Whether you’re prototyping a new product or scaling a batch production run, Geomiq is your one-stop CNC machining partner.

- Upload your CAD design on our instant quoting platform

- Choose from 100+ material options

- Get your finished parts delivered in as little as 3 days

- Enjoy free DFM checks and expert advice from our engineers

From what is CNC machining to production-ready parts, we’re here to help you manufacture smarter.

About the author

Sam Al-Mukhtar

Mechanical Engineer, Founder and CEO of Geomiq

Mechanical Engineer, Founder and CEO of Geomiq, an online manufacturing platform for CNC Machining, 3D Printing, Injection Moulding and Sheet Metal fabrication. Our mission is to automate custom manufacturing, to deliver industry-leading service levels that enable engineers to innovate faster.

Join us on the path to better, faster and stronger innovation

All uploads are secure and confidential.