CNC MACHINING ESSEX | ONLINE PARTS

For CNC Machining services in Essex, Geomiq has the tools, partners, and capabilities for the job. Upload your designs today, and receive your completed CNC machined parts in just five working days.

OUR ESSEX PROCESS

ORDER HIGH-QUALITY CNC MACHINED PARTS IN ESSEX

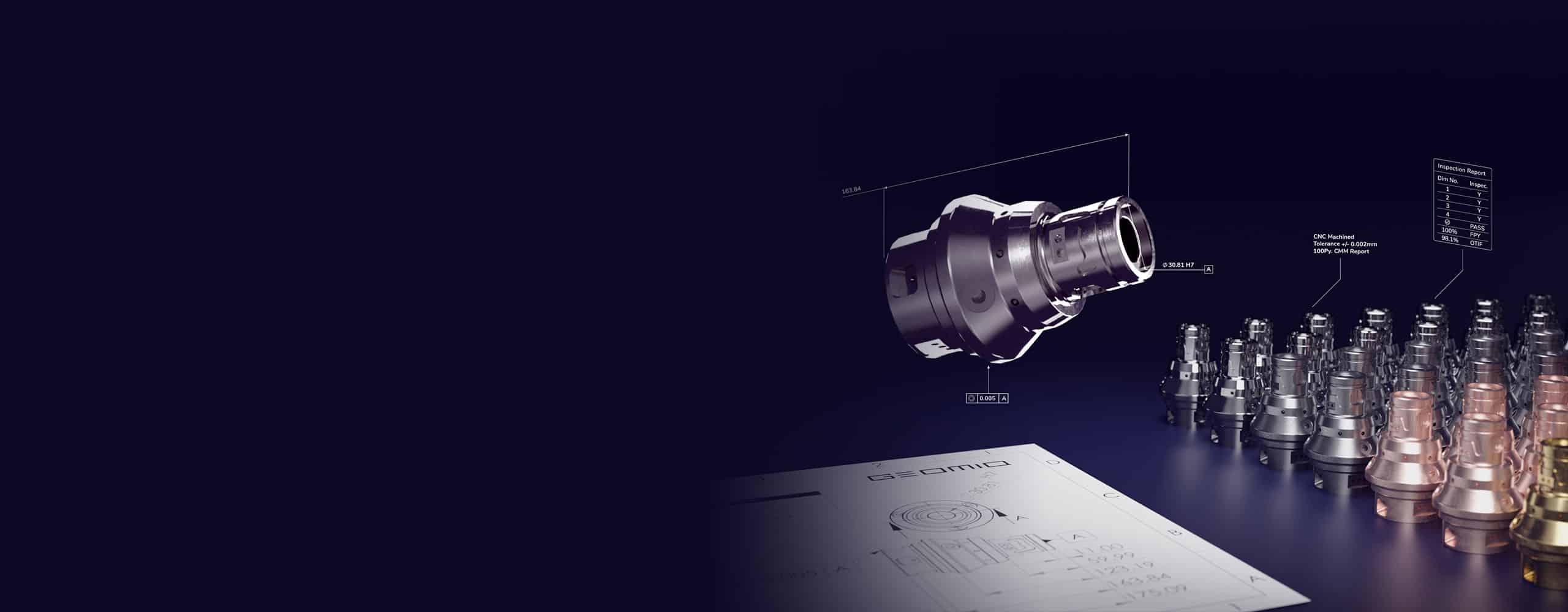

Why order CNC machined parts to Essex with Geomiq? We take the hassle out of the traditional ordering process by streamlining everything into one easy step. With over 180 industry-leading manufacturing partners, you can guarantee we’ll match you with the best in the business for the job. With high tolerance and precision capabilities, unmatched scalability, and a rigorous quality control process, you can have peace of mind that your order will be exactly as it needs to be every time. We offer over 100 different materials and secondary finish options, so we can supply you with your exact components no matter the purpose.

OUR CNC SERVICE ESSEX CAPABILITIES

CNC ESSEX BIRMINGHAM

Our diverse, global supply chain offers an extensive range of capabilities. Whether you are looking for one-off prototypes or large-scale batch manufacture, we can deliver repeatedly on quality and lead time. Our partners operate virtually every kind of CNC machine, including mills, lathes, mill-turns, multi-axis machines, sliding head lathes and bar fed lathes. We also offer CNC grinding and EDM processes. This allows us to utilise the correct tool for the job to meet requirements at a competitive price.

CNC ESSEX BIRMINGHAM

With our standard tolerance being +/- 0.127mm on all CNC Turned parts and the ability to refine that even more, Geomiq offers only the best CNC Turning services. With 1400+ machines in our network, we guarantee a great price while maintaining the highest level of quality and fastest delivery possible. So if you are looking to have parts turned with a high level of accuracy and need parts made right the first time, you have come to the right place.

WHY ORDER CNC MACHINED PARTS FROM GEOMIQ?

RAPID TURNAROUND

We’re committed to reducing friction at every stage, so you can be as delighted with the speed of your CNC Machined parts’ arrival as you are with their exceptional quality. Order now to receive your parts in as little as 5 days!

HIGH ACCURACY

Our standard CNC tolerance is +/- 0.127mm, and when you use our tolerance configurator, you can expect precision machining down to +/- 0.005mm.

UNMATCHED SCALABILITY

Whether you’re after a one-off prototype or 10,000 units at the most competitive price, Geomiq’s world-class supply chain can deliver.

THE PERFECT FINISH

We offer high-quality finishing processes for most CNC Machined parts; from anodising, polishing and plating, to powder coating and more.

A WIDE VARIETY OF MATERIALS

We offer over 100 plastic and metal materials, and take great care to ensure the right material is used for every part. Please get in touch if the material you require is not listed.

A WIDE RANGE OF INDUSTRIES

With customers in every industry, from aerospace, defence, robotics, medical and automotive to electronics, Geomiq has a wealth of experience meeting a diverse range of requirements. Calling on our world-class supply chain, we can meet any requirements.

QUALITY ASSURANCE AT EVERY STAGE

We’re committed to providing the best quality assurance in the business. We employ highly skilled Essex engineers to triple-check all of your files and parts from initial quote to final inspection – ensuring that you’re happy with your results the first time, every time.

FROM PROTOTYPE TO PRODUCTION IN DAYS

At Geomiq, we know your time is valuable – and we’re passionate about helping you save more of it. When you upload your files, we’ll get you a quote within one business day – and our network of highly experienced partners in Essex will ensure the finished CNC products are of the highest quality with short lead times.

LEVERAGE THE EXPERTISE OF OUR ESSEX PARTNER NETWORK

We partner with 180+ highly vetted and experienced CNC manufacturers from a number of countries, so that you can benefit from a world-class supply chain, offering greater capabilities and the highest standards in the world – all from a single access point.

CNC MACHINING MATERIALS ESSEX

Aluminium

Stainless steel

Copper

Brass

Magnesium

Steel alloy

Titanium alloy

Plastics

POST-PROCESSING AND FINISHING OPTIONS

As-machined

Coating services

Surface finish

Heat treatment

WHAT IS CNC MACHINING?

CNC Machining is a form of subtractive manufacturing. This means CNC Machining starts with a block of material (called a blank), and uses fast-moving cutters to quickly carve away material and create the finished part. This involves the automated control of machining tools (such as drills, boring tools and lathes) by means of a computer. These CNC machines process each piece of material to meet specifications by following a coded programmed instruction, and once programmed can manufacture the part autonomously.

OUR CNC MACHINING

Join us on the path to better, faster and stronger innovation

All uploads are secure and confidential.