How to Reduce CNC Machining Costs

CNC machining is a versatile manufacturing process that accurately produces numerous complex parts and geometries. However, as in other manufacturing processes, CNC machining cost is a vital consideration for businesses, customers, and CNC machining service providers alike, as it affects resource management, profitability, and decision-making. This article will explore highly effective strategies to reduce CNC machining costs without impacting product quality.

Factors that Affect CNC Machining Cost

Effective Strategies to Reduce CNC Machining Costs

1. Simplify Parts

2. Conduct Thorough Material Selection

3. Optimise Design Via Design For Manufacturing (DFM)

4. Minimise Material Wastage

5. Only Specify Necessary Tolerances

6. Specify Standard Surface Roughness Values

7. Incorporate Over-the-shelf Components

8. Specify Relevant Finishes

9. Create Prototypes before Large Scale Production

10. Order Parts in Batches

11. Identify Costs Upfront

Conclusion

Why Choose Geomiq?

Factors that Affect CNC Machining Cost

Before learning how to reduce CNC machining costs, it is important to answer the following question: How much does CNC machining cost? CNC machining is highly versatile and can manufacture parts to various preferences and specifications. These specifications and preferences impact the manufacturing process and significantly vary costs. The following are the factors that affect CNC machining costs.

- Material selection: Rarer materials like titanium or Inconel are more expensive. In addition, harder materials take more time, effort, and resources to machine, driving up both material and tooling costs. Conversely, more machinable materials, like aluminium, are cheaper and faster to machine.

- Production volume: CNC machining has fixed initial design, tooling, and setup costs. Larger production volumes spread these costs over more parts, reducing the cost per unit. In one-off or small-batch production, the reverse is the case, as fewer products bear the initial costs.

- Part complexity: Complex parts require specialised tooling, advanced machining, and more skilled operators, increasing both machining time and operator involvement, thus raising costs. The CNC machine cost of 5-axis machines required for highly complex parts also impacts the CNC machining price per part.

- Tolerance: Tight tolerances require more precise machining, often involving additional passes and tighter quality control. This increases time, resource consumption, and CNC machining costs.

- Surface roughness: Achieving a high-quality surface finish requires slower machining speeds, more passes, or additional finishing processes like polishing, which can add to production time and expense.

- Post-processing: Additional operations like heat treating, painting, or anodising can significantly add to the overall cost. These processes require extra labour, materials, and time.

Design, manufacturing techniques, and machining conditions also impact the final cost of CNC machined parts. We will explore these factors in more depth in subsequent sections of the article.

Effective Strategies to Reduce CNC Machining Costs

The following are 11 practical strategies to reduce CNC machining costs without sacrificing product quality.

1. Simplify Parts

Part complexity influences CNC machining costs in several ways. To begin with, the more complex a part is, the more time and effort it takes to create. Operators spend more time creating tool paths and producing tooling. Complex parts with intricate geometries typically require continual repositioning of the workpiece to grant the cutting tool access to different areas of the workpiece, thereby increasing machining time. 5-axis CNC machines position the workpiece automatically. However, the CNC machine cost of 5-axis machines, specialised tooling, and the skill required to operate them make 5-axis machining more expensive than its 3-axis counterpart.

Part complexity also influences CNC machining costs via specialised tooling costs. For example, jigs and fixtures are necessary to hold and position the workpiece during machining to provide access to the cutting tool. Machinists can position simple parts with generic shapes using generic fixtures. However, complex parts require custom fixtures designed with the end product's geometry in mind. These parts may also require specialised cutting tools, such as custom CNC milling tools, which result in higher costs. Furthermore, as complex parts take more time to produce, they consume more resources, such as cooling systems and cutting tools (due to tool wear). The image below is a costly custom-made pneumatic workpiece holding fixture.

Custom fixtures increase CNC machining costs

Reduce CNC machining costs by simplifying your design, incorporating complex features only when required for functionality. We recommend designing parts that require as little repositioning of the workpiece as possible. You can also split parts that are too complex to achieve in one machining round.

2. Conduct Thorough Material Selection

The choice of material profoundly impacts CNC machining costs. Not only does the actual cost of the material impact overall costs, but the material properties also affect machining time and effort.

Select cost-effective material options: Different applications require specific material properties. Select the most cost-effective material that meets your application requirements to reduce the cost of CNC machined parts. For example, aluminium 6061 is more cost-effective than stainless 316 steel in an application that requires strength and durability in a non-corrosive environment. Similarly, ABS plastic is a less expensive alternative to nylon in non-load-bearing applications.

Material availability: Materials vary in availability, and their prices reflect this. Save CNC machining costs by selecting readily available material options for your part. For example, aluminium and brass are typically more available than titanium and cobalt. When considering availability, also review different alloys of the same metal. For instance, aluminium 6061 is more available and less expensive than aluminium 7075.

Consider Machinability: Materials vary in how easy or difficult they are to machine. High-hardness metals or certain plastics may require slower cutting speeds, hardened tools, and more frequent tool changes, increasing production time and CNC Machining costs. Materials with better machinability, such as aluminium or brass, facilitate faster processing, less tool wear, and lower production costs. Always factor in machinability when selecting materials to reduce CNC machining costs.

3. Optimise Design Via Design For Manufacturing (DFM)

Design for manufacturing, the practice of optimising designs for seamless manufacturing, not only results in better products but can also significantly reduce the cost of CNC machining. The following are some CNC machining design for manufacturing tips that help you save costs.

- Simplify Geometry: Avoid complex shapes and intricate features unless necessary. Simple geometries, like straight edges, flat surfaces, and symmetrical designs, are easier and faster to machine.

- Design for Standard Tooling: Use dimensions and radii that align with standard cutting tools. Avoid custom-sized dimensions or unusual angles that require special tooling. Using readily available tools reduces tooling costs and setup times.

- Avoid thin walls: Design walls with a minimum thickness of 0.8 mm (for metals) or 1.5 mm (for plastics) to prevent warping or damage during the CNC milling process. Thicker walls are easier to machine and prevent material wastage, reducing both machining and material costs.

- Optimise Part Orientation: Design parts to minimise the number of setups needed for machining by aligning features for optimal machining in fewer operations. This reduces setup time and labour costs.

- Limit Use of Threads: Use threaded features sparingly to reduce machining time, tool wear, and the potential for errors in threading operations. Opt for inserts where applicable, especially for small threads.

- Avoid Small Features: Design features large enough for standard tools to machine efficiently. Small features often require additional tool changes and slower machining speeds.

- Limit aesthetics features: Avoid aesthetic features, such as decorative cuts, embossments, and lettering on predominantly functional parts. Such features increase machining time and are not vital to part functionality.

Reduce CNC machining costs by optimising designs

While some of these practices do not individually save a lot of cost, they collectively significantly reduce CNC machining costs. See our CNC design guide for everything you need to know about optimising your designs for manufacturing.

4. Minimise Material Wastage

CNC machining processes start with a block of raw material called a blank. As a subtractive manufacturing technique, CNC machining creates parts by cutting away pieces of the blank until the part forms, with the carved away pieces constituting waste. Depending on the part's complexity, this technique results in material wastage of 30% to 70% of the original blank volume. Available in standard sizes, blanks have specific costs determined by weight and volume. Therefore, CNC machining technically wastes 30% to 70% of material cost.

CNC Machined part compared to the initial blank volume

Minimising material wastage and optimising usage is a very effective way to reduce CNC machining costs. Optimise material usage by using a blank that closely matches the bounding volume of the part. You can obtain the bounding volume of your model using CAD/CAM software. Machine-ready blanks are available as standard-sized plates ( for CNC machining) and rods (for CNC turning), which you can cut down to size before loading them onto the CNC machine. You can also cast or mould custom blanks. See our article on CNC machining blanks to learn more. Another way to minimise material wastage is to design simpler parts. Complex features with intricate bends, cavities, and geometries require more material removal to actualise.

5. Only Specify Necessary Tolerances

CNC machining is highly accurate and can machine parts with over 99.5% accuracy. While it is crucial in certain applications, such as dynamic matic parts, many applications do not require this level of accuracy. Errors, mishaps, and machining conditions in the CNC machining process, even slight ones, can impact tolerance. Avoiding or mitigating these occurrences requires meticulous attention to detail, increasing machining time and effort. For example, machinists must keep tool deflection, vibrations, and workpiece movement at the bare minimum. This effort requires dampening devices, special clamping and holding tools, and probes and sensors to align the cutting tool properly.

Reduce CNC machining costs by specifying only necessary tolerances

Furthermore, precise cutting speed, slow feeds, and shallow cuts are also required to achieve tight tolerances. In addition, tight tolerances require cooling systems to prevent expansion and chip accumulation. Lastly, during and after machining, the parts undergo quality inspections to ensure they meet the specified CNC machining tolerances. All these considerations, processes, and requirements significantly impact CNC machining costs. In summary, the tighter the tolerance, the more the production costs. Reduce CNC machining costs by specifying tolerance only where required, taking care not to specify tighter tolerances than necessary. The default tolerance of ± 0.127 mm is already quite accurate and sufficient for most applications.

6. Specify Standard Surface Roughness Values

Four industry-standard CNC machining surface roughness levels exist that you can specify for your parts:

- 3.2 µm Ra

- 1.6 µm Ra

- 0.8 µm Ra

- 0.4 µm Ra

These levels are in decreasing order of roughness, with 3.2 µm being the “roughest” and 0.4 µm being the “smoothest”. They are also in increasing order of cost as they increasingly require more effort to achieve. 3.2 µm Ra is the default standard manufacturers apply. This roughness level has visible markings but is sufficient for many applications. As the baseline level, a 3.2 µm Ra roughness level does not incur additional cost. Specify this level where surface roughness isn't crucial.

1.6 µm Ra and below is achieved via increasingly meticulous machining, slow feeds, shallow cuts, and close control, with 0.4 µm Ra requiring post-machining polishing to achieve. These requirements increase machining time, effort, and, therefore, cost. In general, 1.6 µm Ra, 0.8 µm Ra, and 0.4 µm Ra cost an additional 2.5%, 5%, and up to 15% above the base price, respectively.

Specify only relevant surface roughness to reduce CNC machining costs

Surface roughness is crucial in specific applications. However, specifying an overly smooth surface in applications where it is inconsequential is a waste of resources. Reduce CNC machining costs by selecting the surface roughness level necessary for your part’s functionality and application. See our CNC machining surface roughness article to learn how to choose the correct Ra value for your application.

7. Incorporate Over-the-shelf Components

While CNC machining can produce a wide range of products, machining every component is not always necessary. Various machinable parts and components in a product or assembly are commercially available. These ready-made components, known as commercial-over-the-shelf (COTS), typically cost less to purchase than sell as they are mass-produced, and economies of scale apply to their prices. COTS components you can incorporate to reduce CNC machining price per part include:

- Gears

- Bushings and spacers

- Bearings

- Shafts and dowel pins

- Fasteners

- Springs

- Hinges

- Couplings

These parts are machinable to custom specifications. However, they are readily available in an extensive range of standard sizes and specifications. Incorporating standard COTS components into your product significantly reduces CNC machining costs.

Lower CNC machining costs by incorporating COTS components

Geomiq offers both CNC machining and product assembly services. Our sourcing experts procure high-quality COTS components from reliable suppliers, and we assemble everything in-house. Contact us to get started.

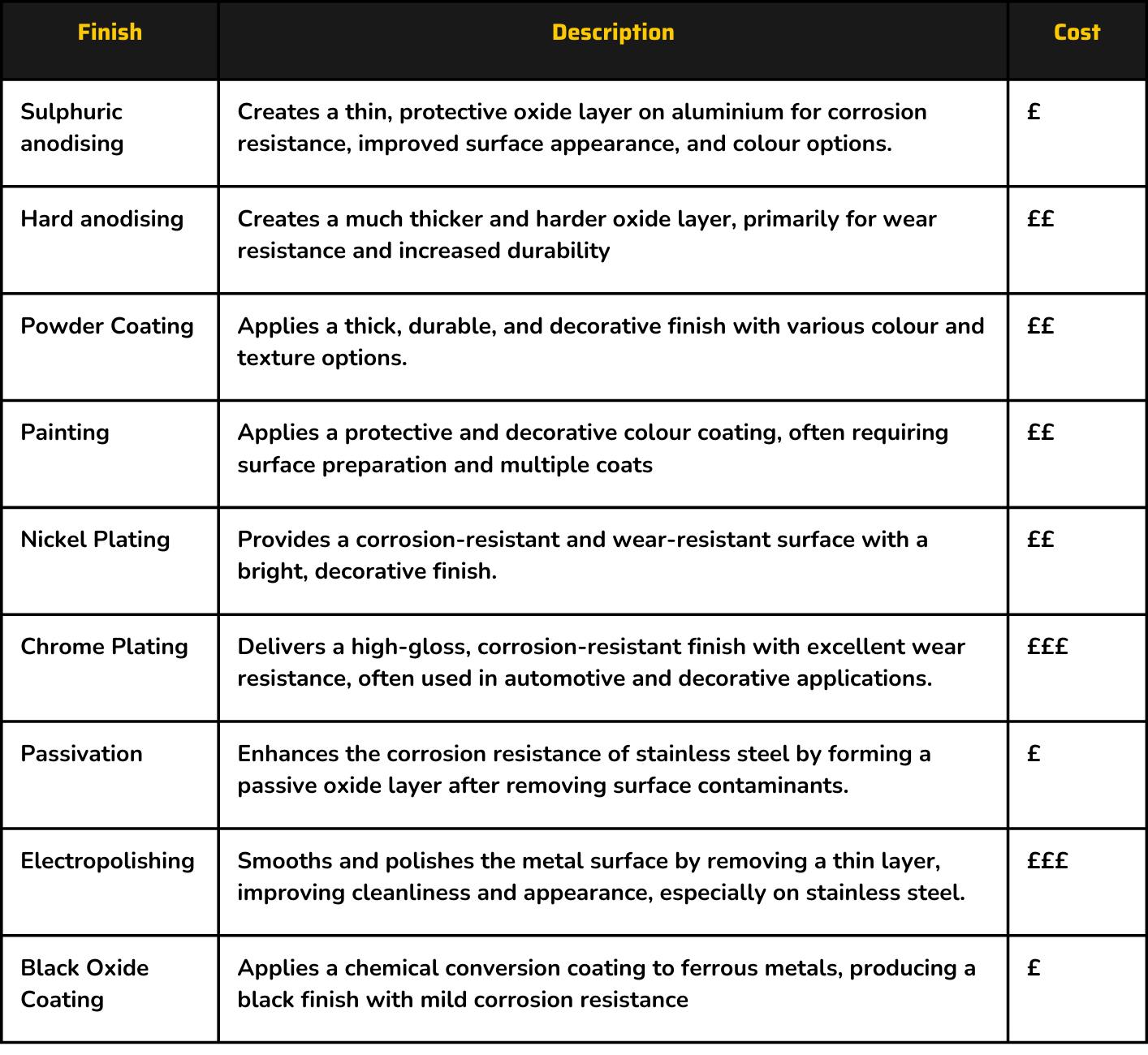

8. Specify Relevant Finishes

Various functional and aesthetic surface finishes are available for CNC machined parts. These finishes vary in cost. Only specify the finishes required by your application to minimise CNC machining costs. The table below compares the cost and benefits of some common sheet metal finishes. See our CNC surface finishes gallery for all available options.

CNC machining finishes and their costs

9. Create Prototypes before Large Scale Production

A vital aspect of creating a new product, especially one you intend to manufacture in bulk, is rapid prototyping. You may design a product that is theoretically sound and functional but, upon manufacturing, discover several functionality flaws. If the product was manufactured in bulk, you end up with faulty products and a considerable loss of resources, including money, time, and effort. Prototyping potentially saves significant CNC machining costs by enabling you to test small quantities of your product to ensure their feasibility and functionality before moving on to bulk production.

10. Order Parts in Batches

While this may sound counterproductive, ordering in batches rather than a single one-off part can significantly reduce CNC machining costs. Here's how - A significant portion of the cost of CNC machining goes to preparation - designing the model, creating and optimising tool paths, performing CAE (Computer Aided Engineering) analysis, and preparing the initial tooling for the part. These one-time initial processes are required and have fixed costs, whether you are manufacturing one part or a thousand. For a one-off single part, the part bears the full setup cost. However, for batch productions, economies of scale apply. The initial setup costs are spread over the number of parts, significantly reducing the CNC machining price per unit. For example, it costs £134, via our instant quoting platform, to machine one unit of the part in the image below from low-cost steel. Ten units cost a total of £385, and 100 units cost £1,300, reducing the cost per unit to £38 and £13, respectively. These price differences represent a 70% and 90% drop in the per unit cost for a single part.

Order parts in batches to reduce CNC machining costs

11. Identify Costs Upfront

Proper planning is critical to keeping your CNC machining costs within budget. It is immensely beneficial to estimate what each aspect of machining will cost ahead of time. With CNC machining services from custom manufacturers like Geomiq, you can see the exact cost of your part ahead of time and how different preferences and specifications affect this cost. Our instant quoting platform allows you to specify part quantity, material, surface roughness, tolerance, primary finishing, and secondary finishing, instantly updating the quote as you make these selections so you can plan adequately.

Conclusion

Reducing CNC machining costs involves combining design optimisation, careful material selection, and efficient manufacturing techniques. By standardising, reducing part complexity, minimising unnecessary features, and choosing cost-effective materials, you can ensure your project is cost-effective without sacrificing quality.

Why Choose Geomiq?

Geomiq offers precise control over CNC machining costs via our instant quoting platform. Simply upload your design to get started with our CNC machining services. Our innovative platform provides options on materials, tolerance, part quantity, and finishing, providing instant to 24-hour quotes based on your preferences.

With a few clicks, you can receive your finished part in as little as three days. Not sure which options are best for your project? Our expert designers and engineers are available to guide you on design, process selection, and custom solutions to ensure seamless, cost-effective manufacturing for your project.