Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

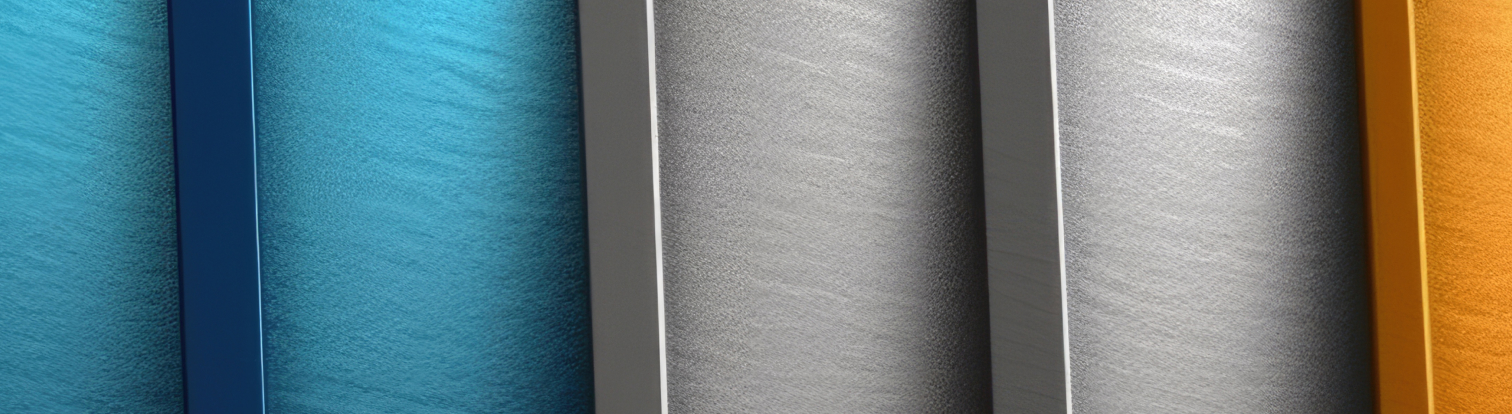

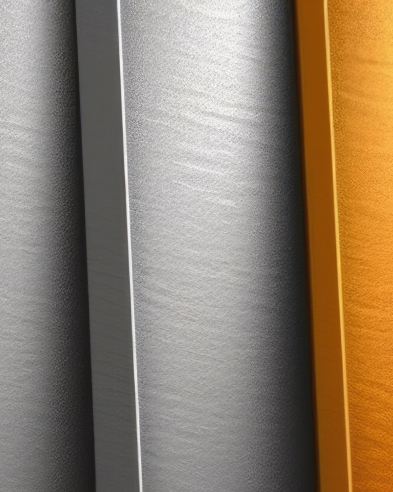

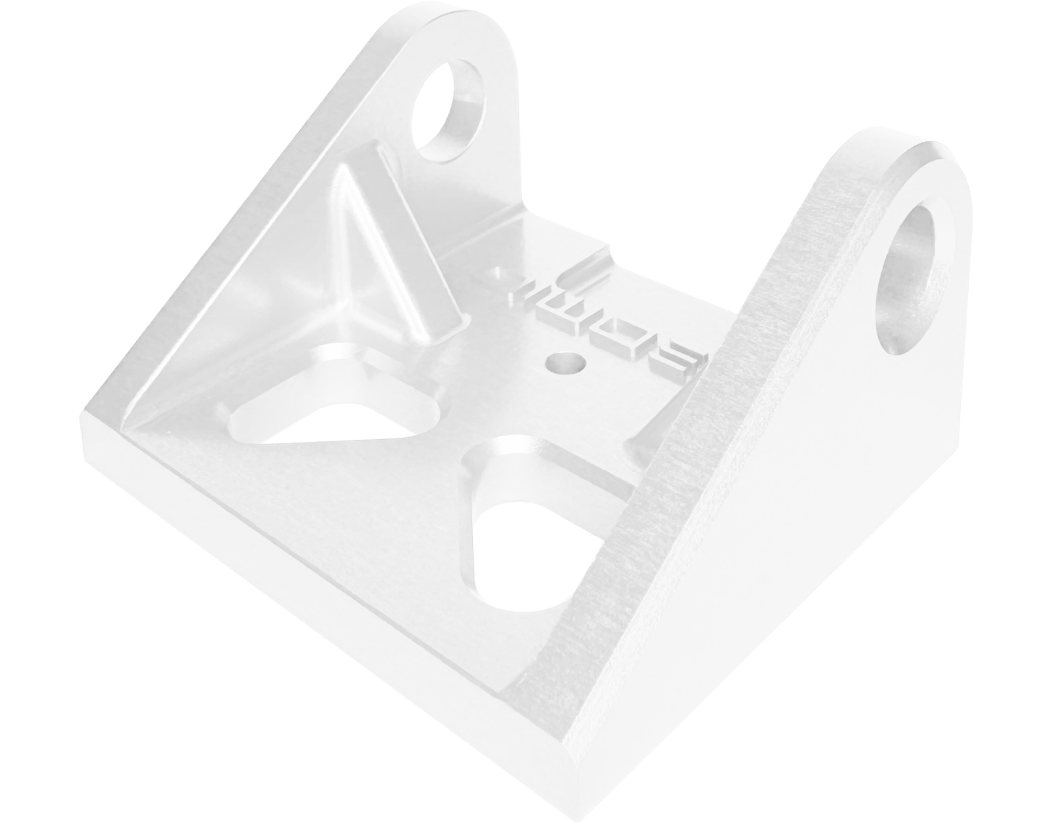

Sheet Metal surface finish gallery

Explore our wide variety of surface finishing options for sheet metal fabrication.

Trusted by

Filter By:

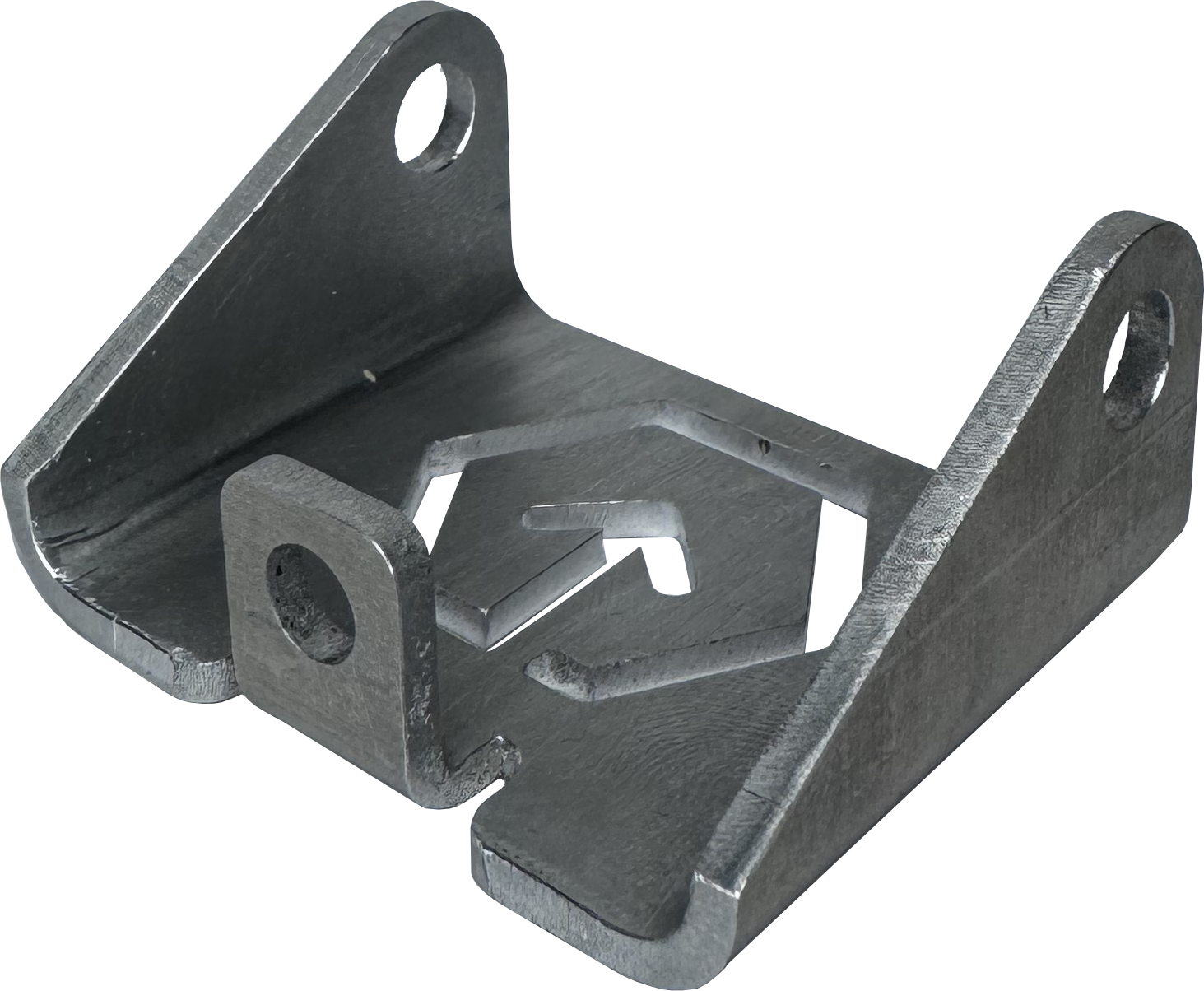

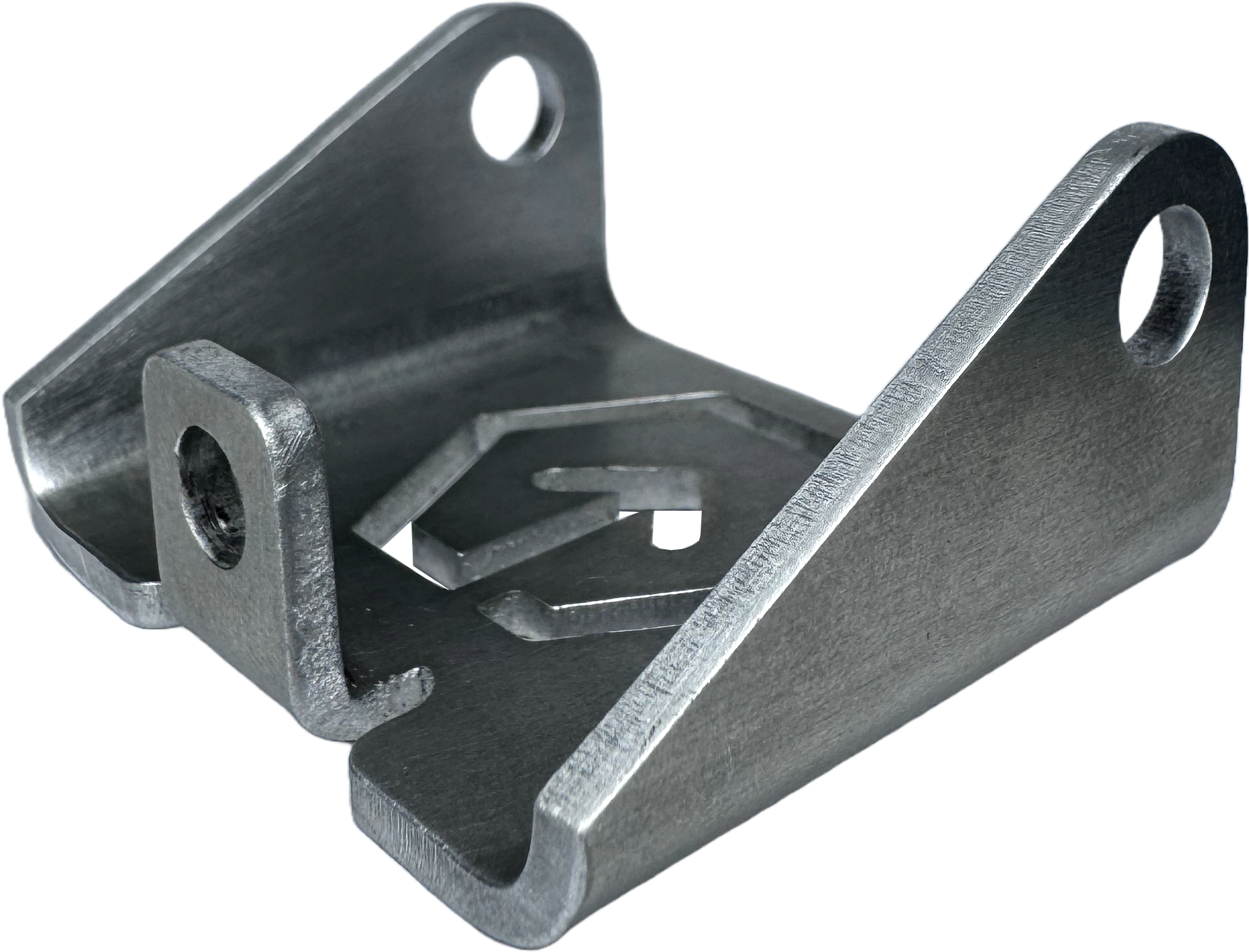

There are various sheet metal surface finishes that are available off the shelf, including brushed and treated variants.

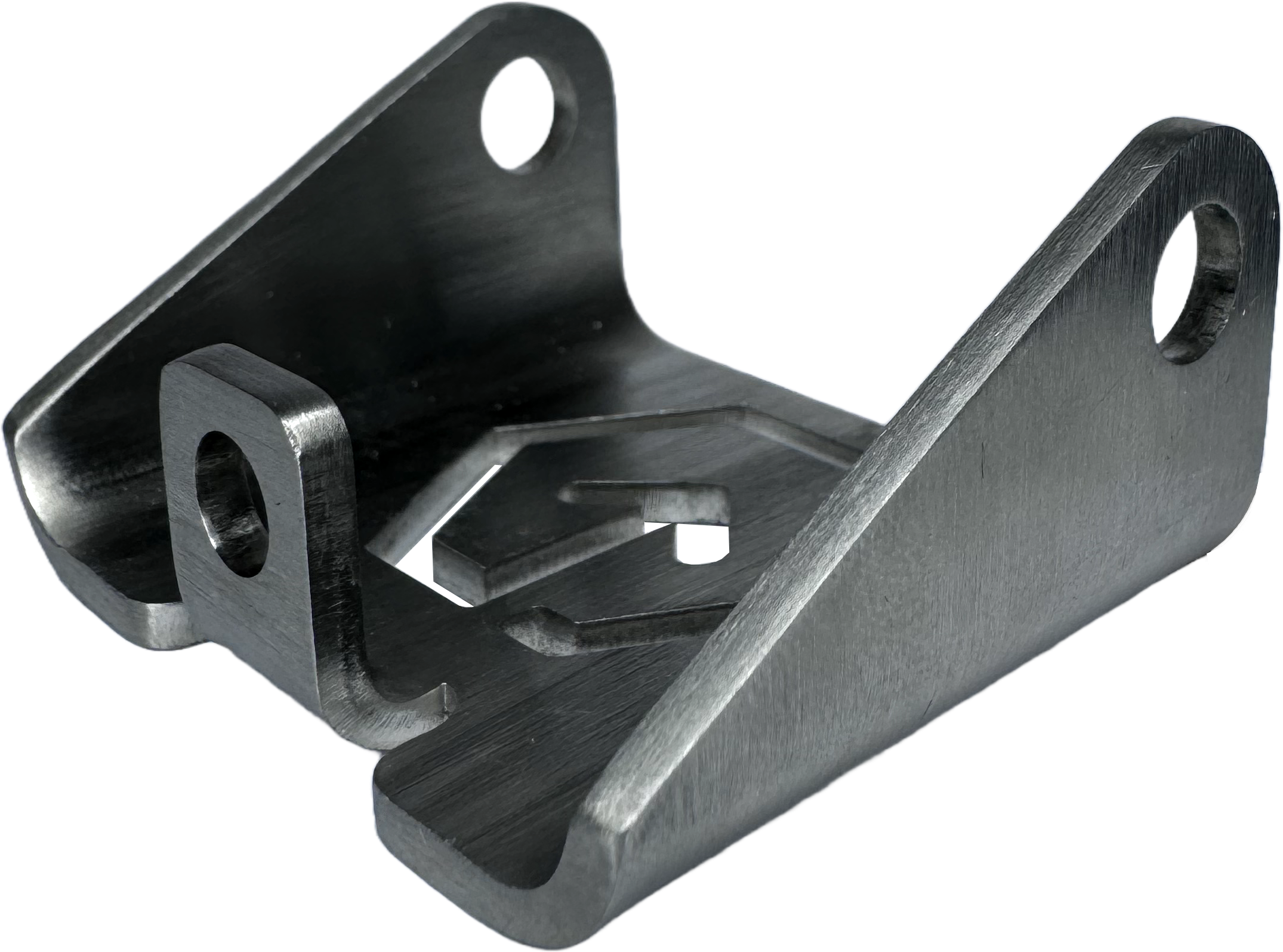

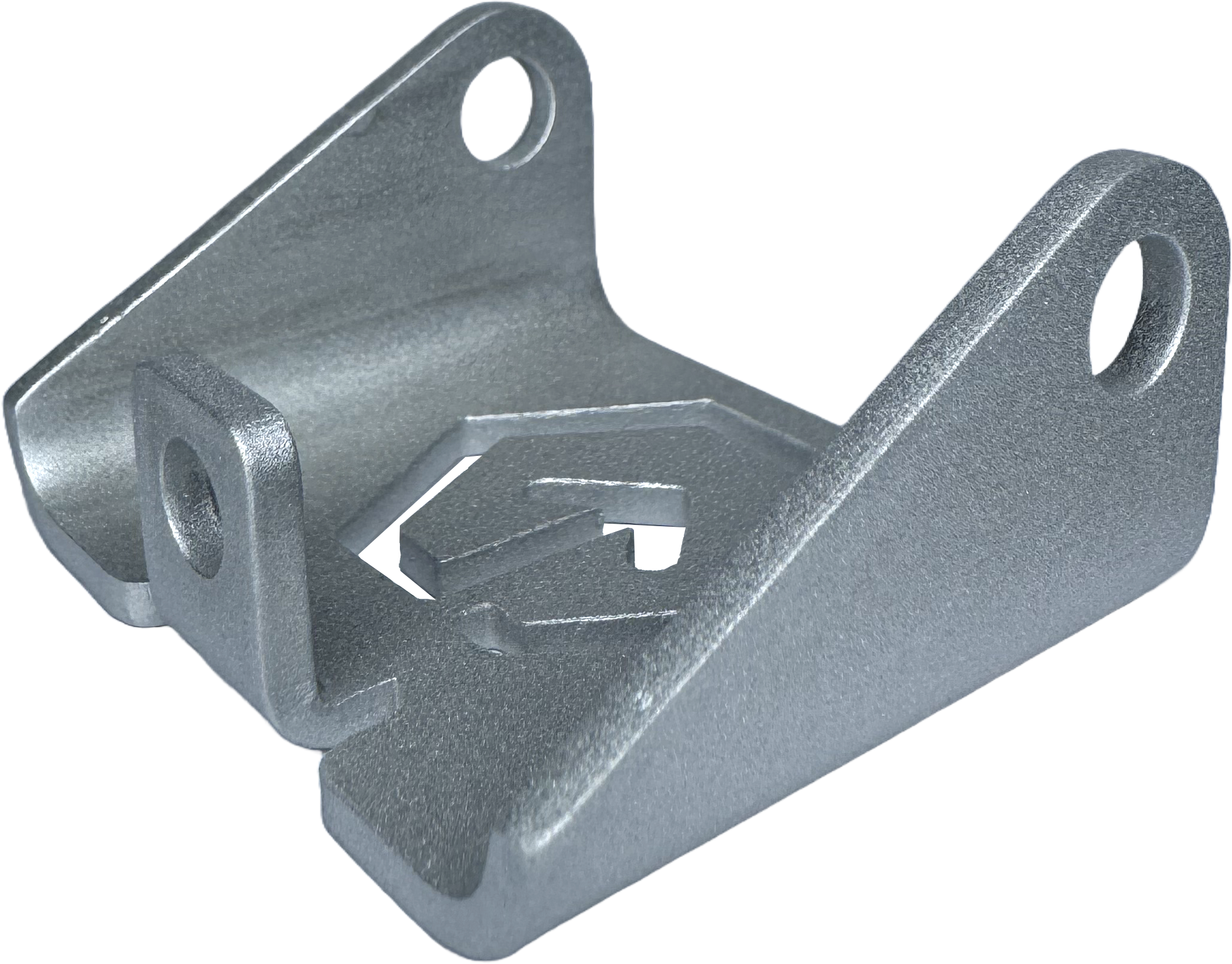

Visible tooling marks and light surface scratches.

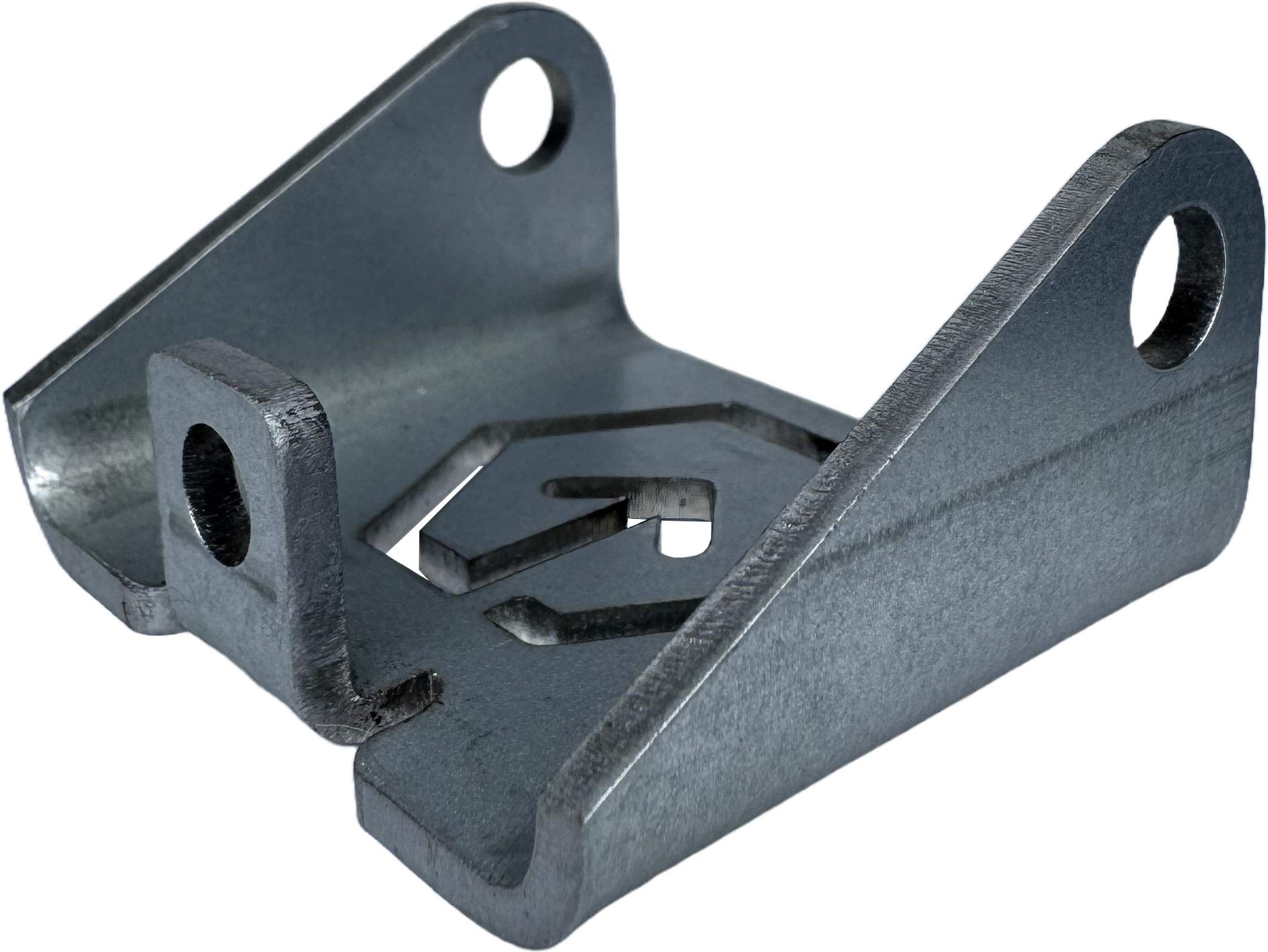

Visible tooling marks and light surface scratches, oil coated to prevent corrosion.

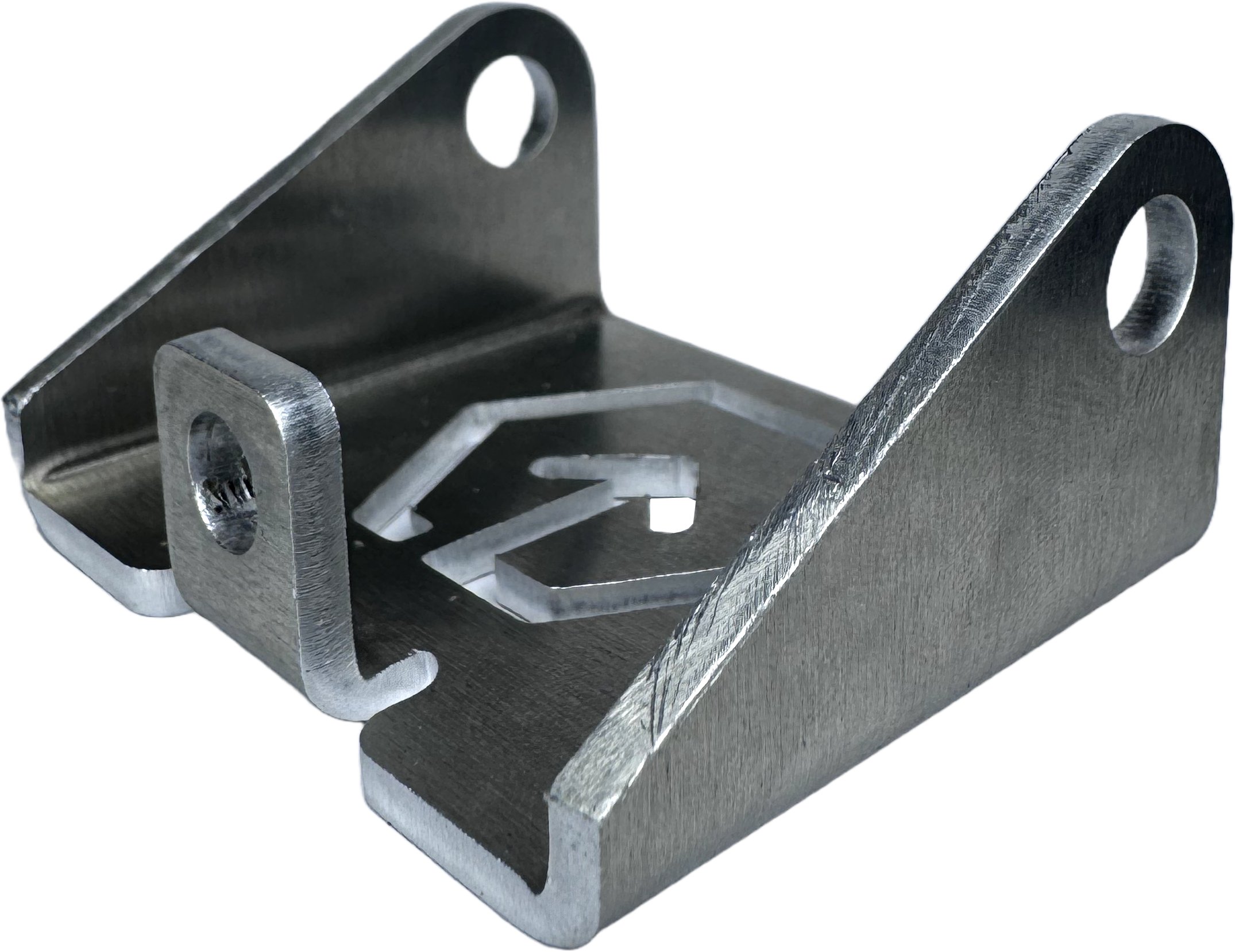

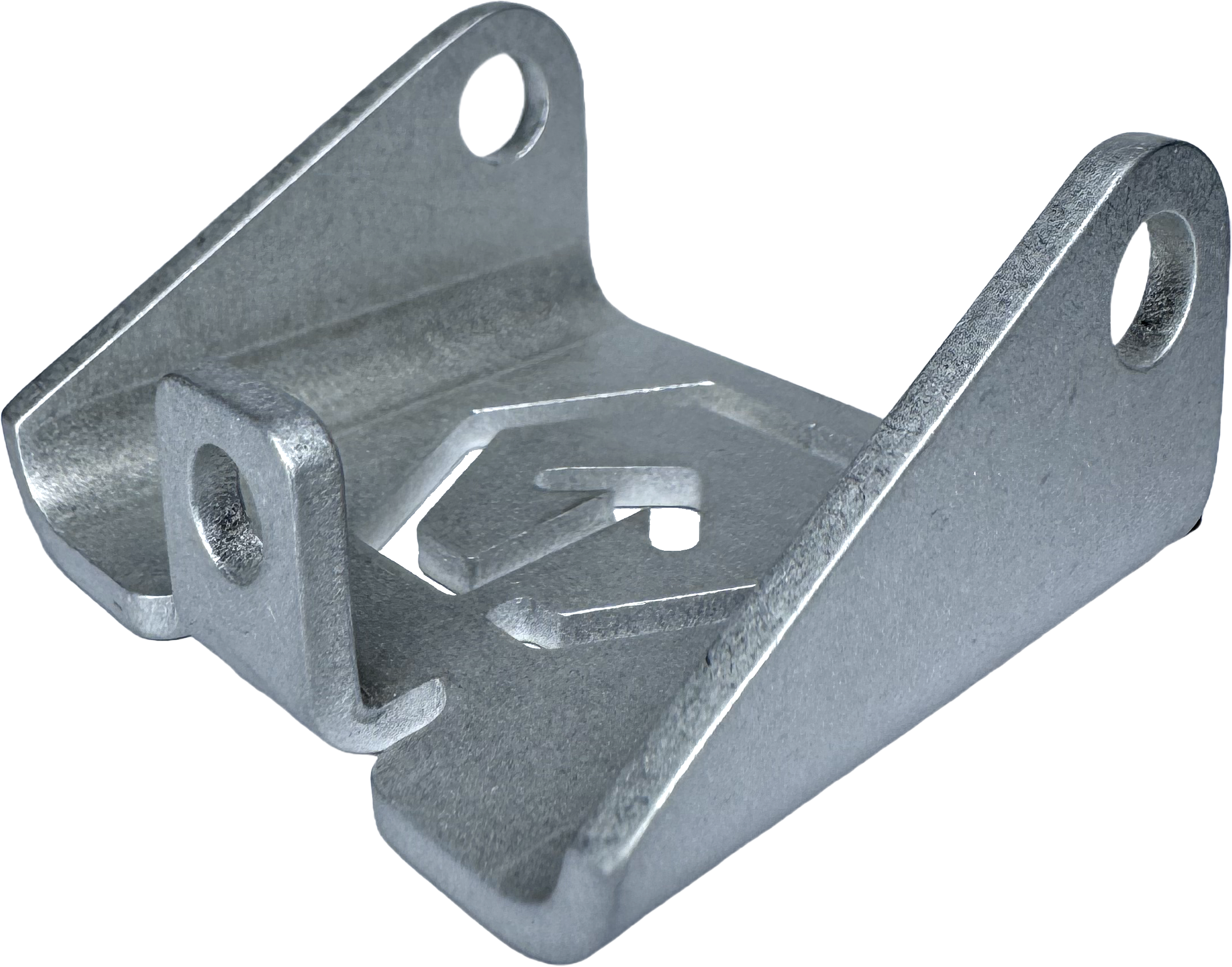

Smooth mill finished, cold rolled and moderately reflective.

Smooth mill finished, cold rolled and slightly more reflective than 2B finish.

Appears with a rough pattern, high level of corrosion resistance.

Brushed one side with 150-180 grit grain in one direction.

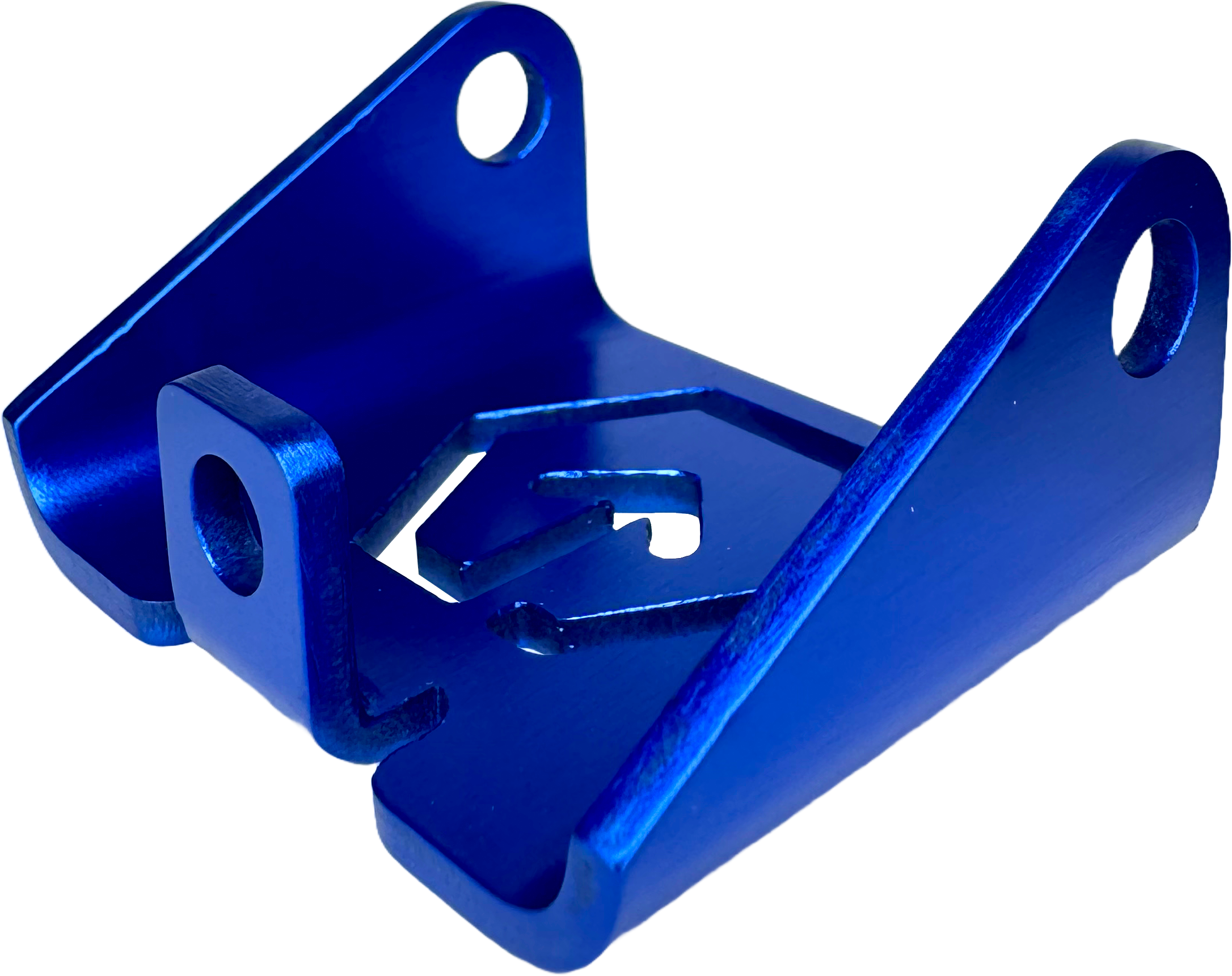

Type 2 sulphuric anodising is usually done to protect the surface or apply a coloured dye to improve aesthetic appeal. Anodised colours can be matched closely to specific Pantone or RAL colours when using our colour tolerance guide. Standard thickness ranges are typically between 5µm to 25µm.

Blue

Provides increased corrosion resistance and improves aesthetic appearance.

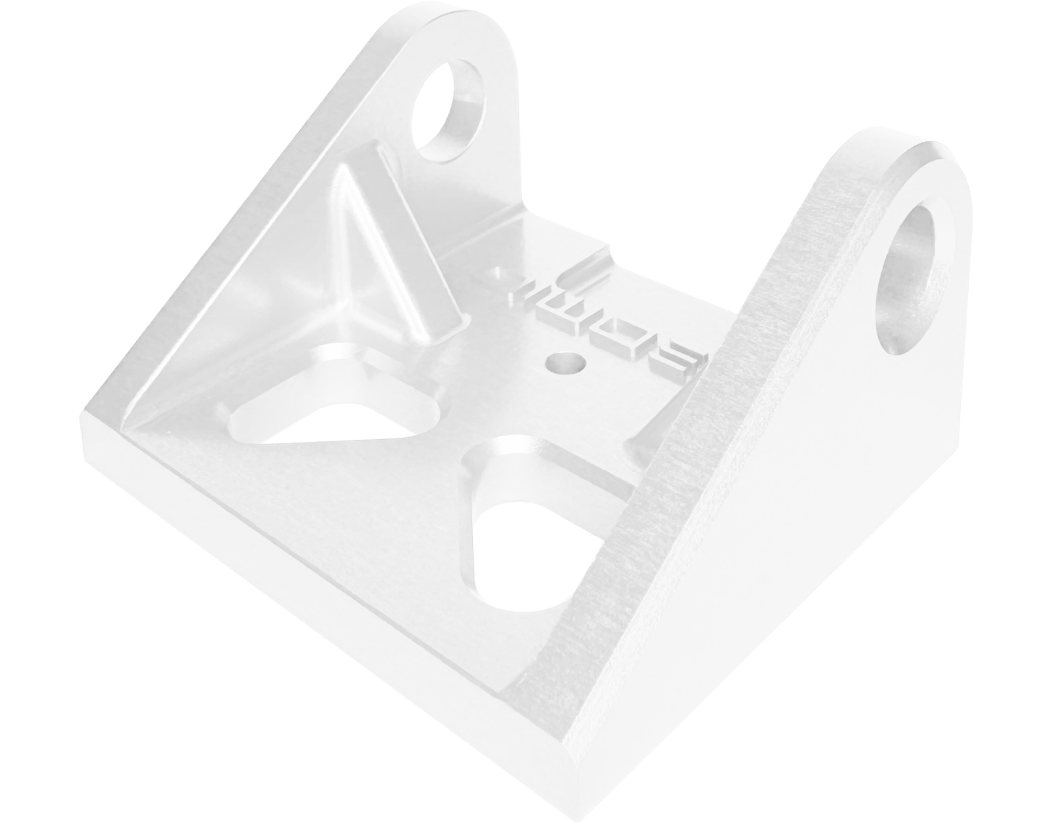

Clear

Provides increased corrosion resistance and improves aesthetic appearance.

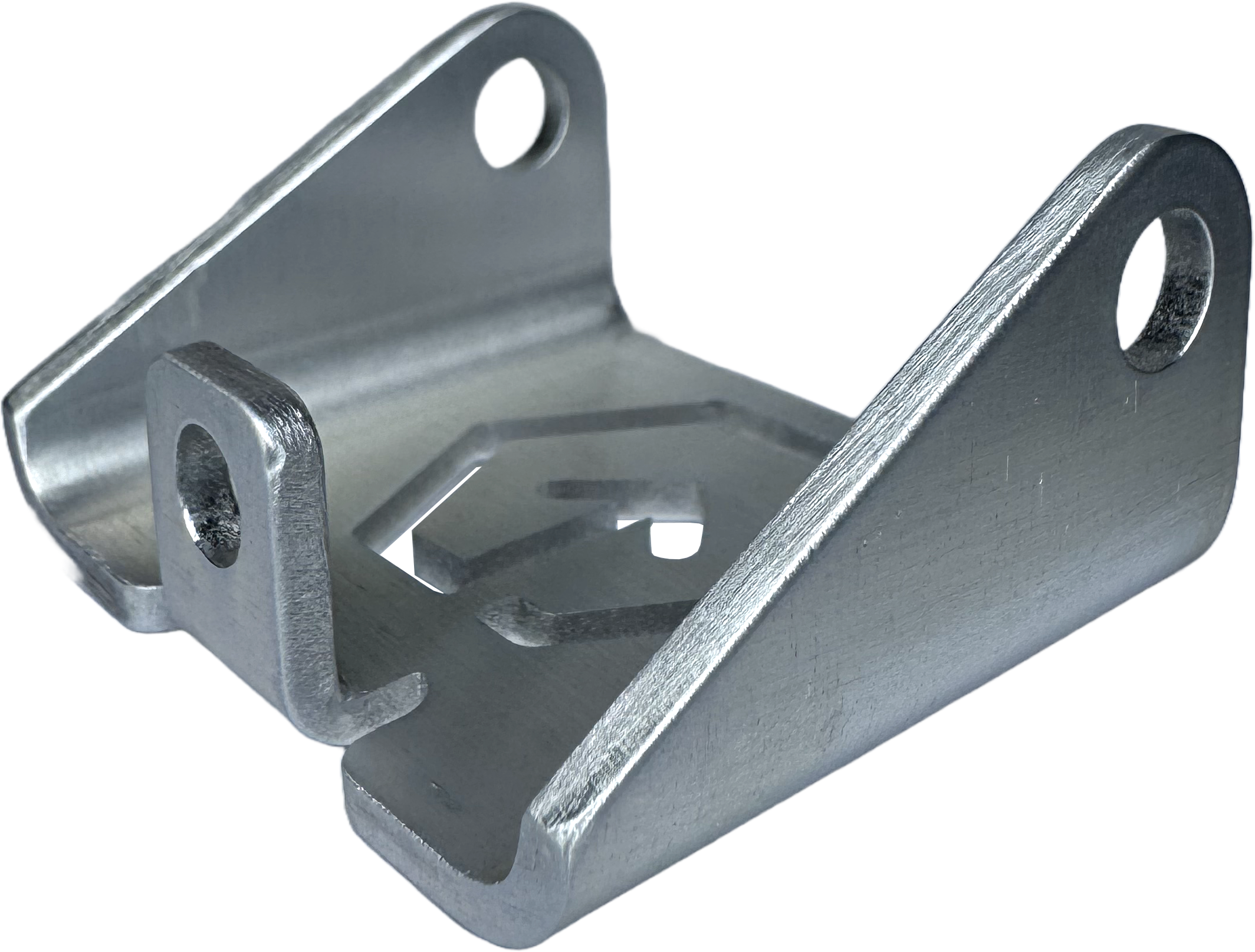

Silver

Provides increased corrosion resistance and improves aesthetic appearance.

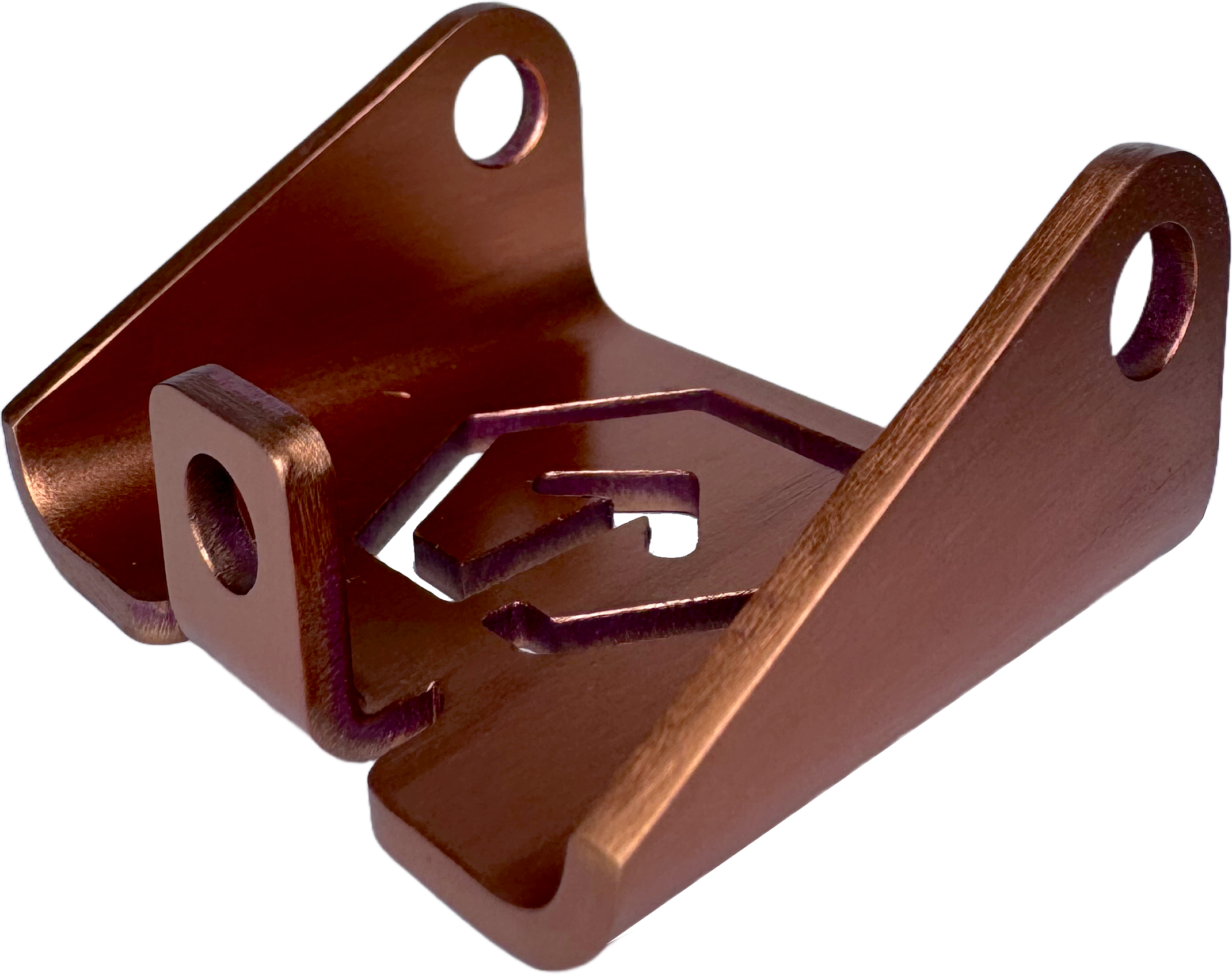

Bronze

Provides increased corrosion resistance and improves aesthetic appearance.

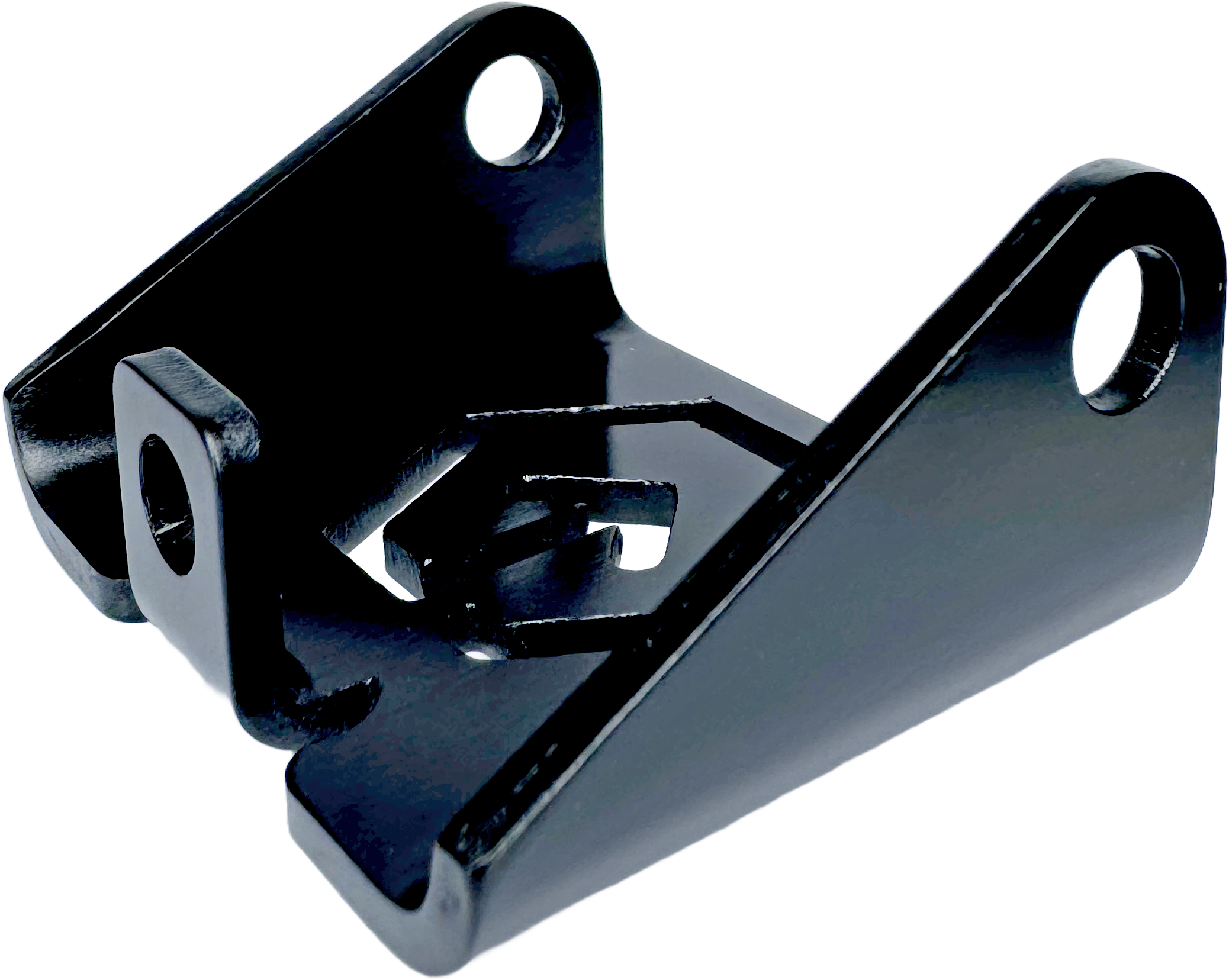

Black

Provides increased corrosion resistance and improves aesthetic appearance.

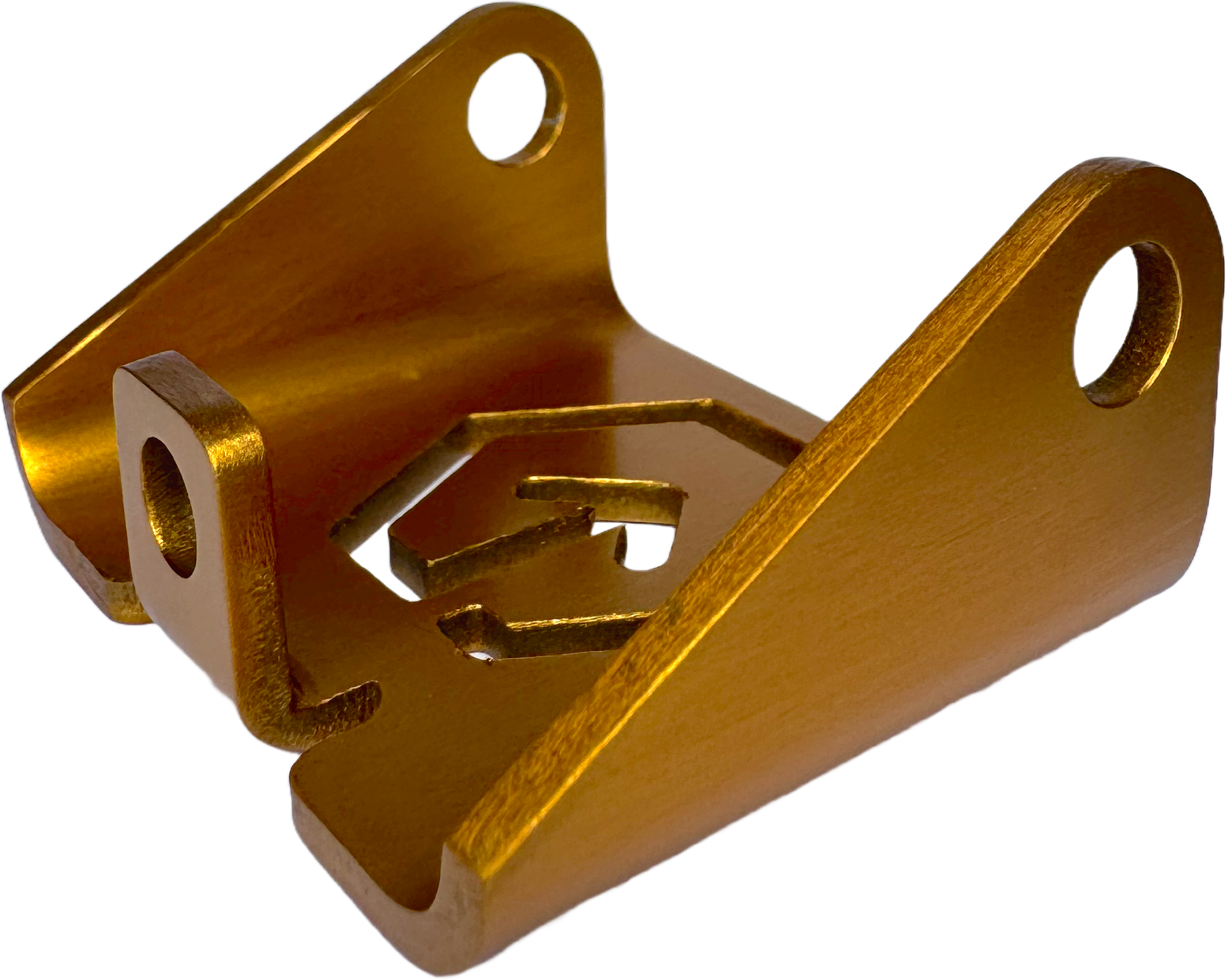

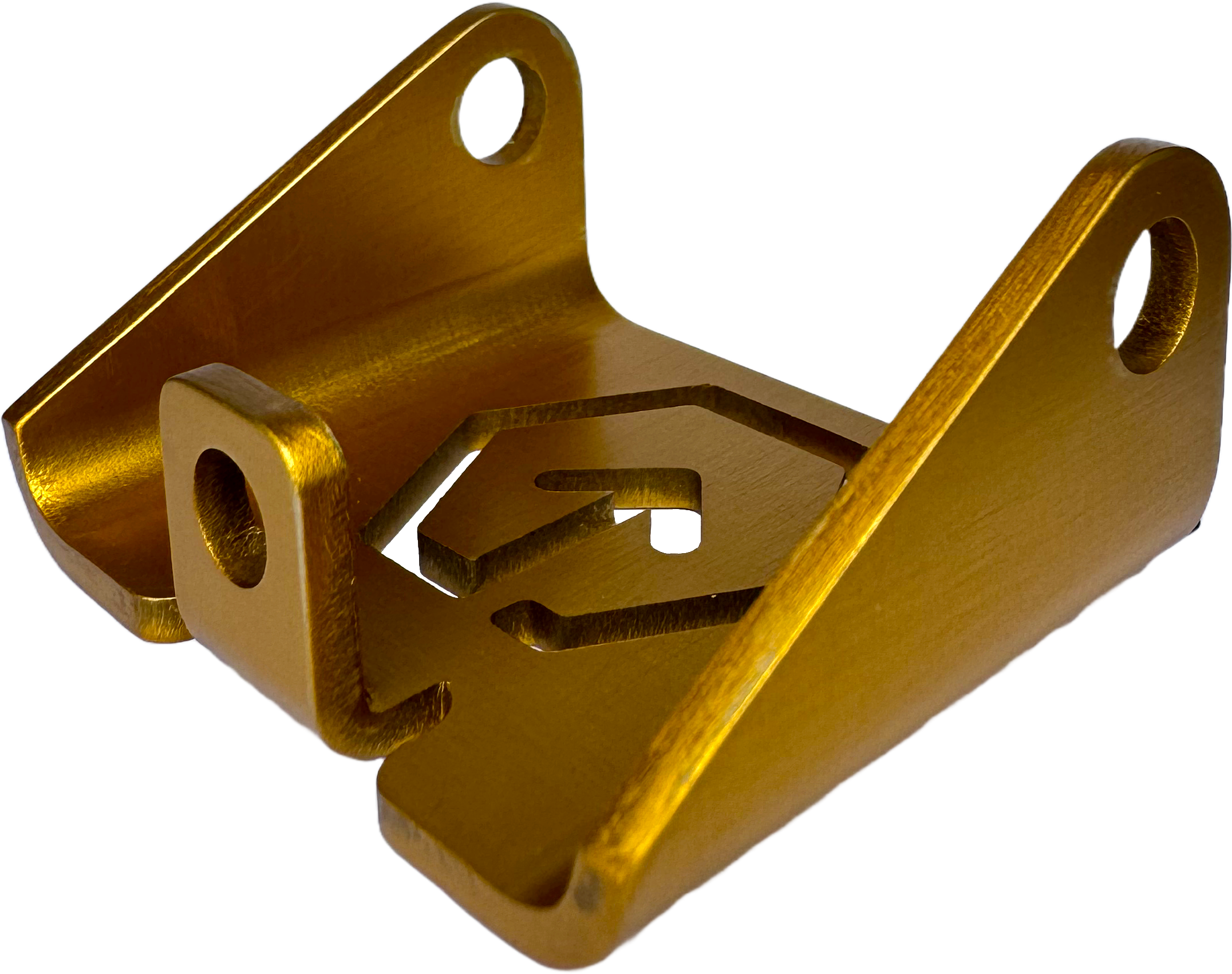

Gold

Provides increased corrosion resistance and improves aesthetic appearance.

Green

Provides increased corrosion resistance and improves aesthetic appearance.

Yellow

Provides increased corrosion resistance and improves aesthetic appearance.

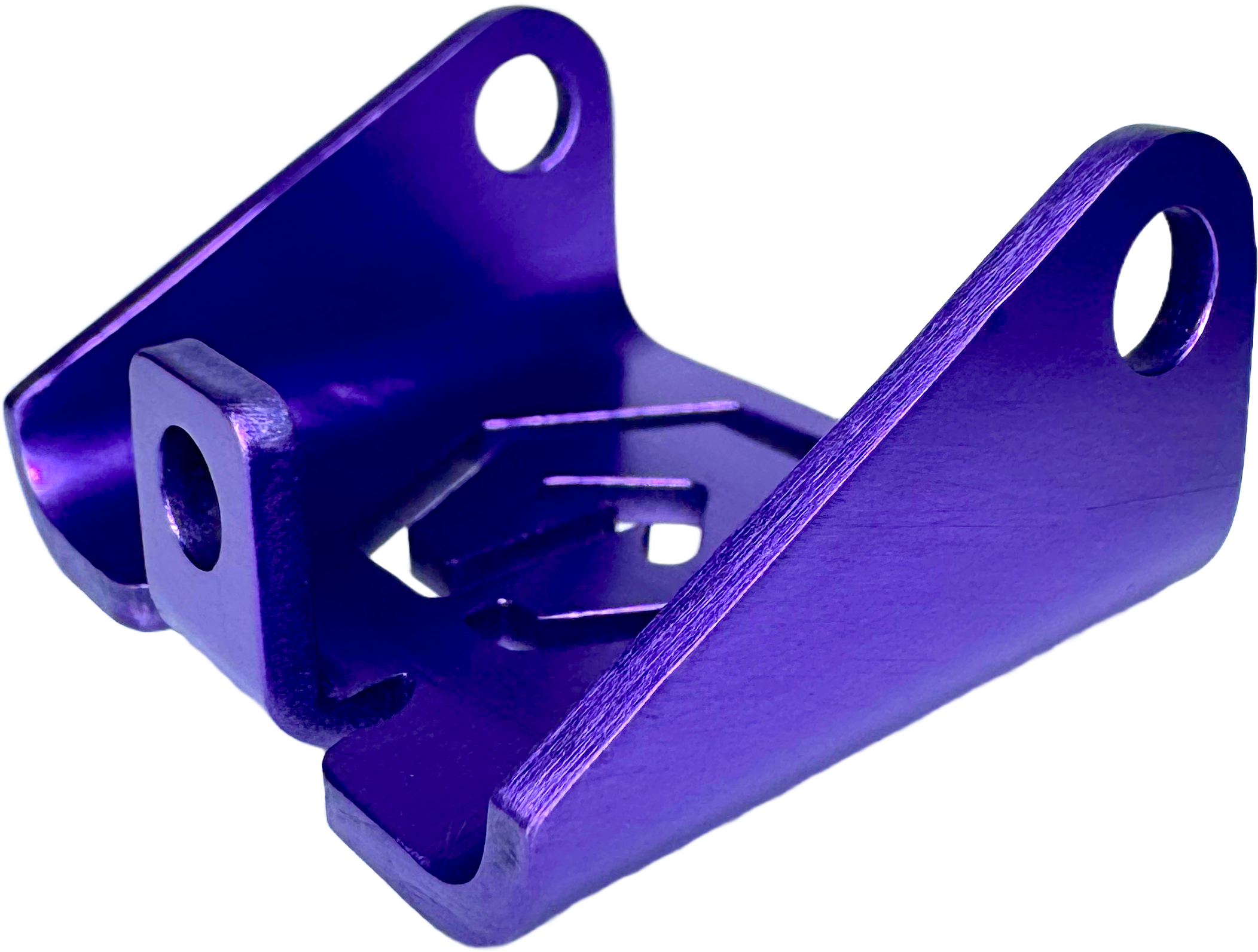

Purple

Provides increased corrosion resistance and improves aesthetic appearance.

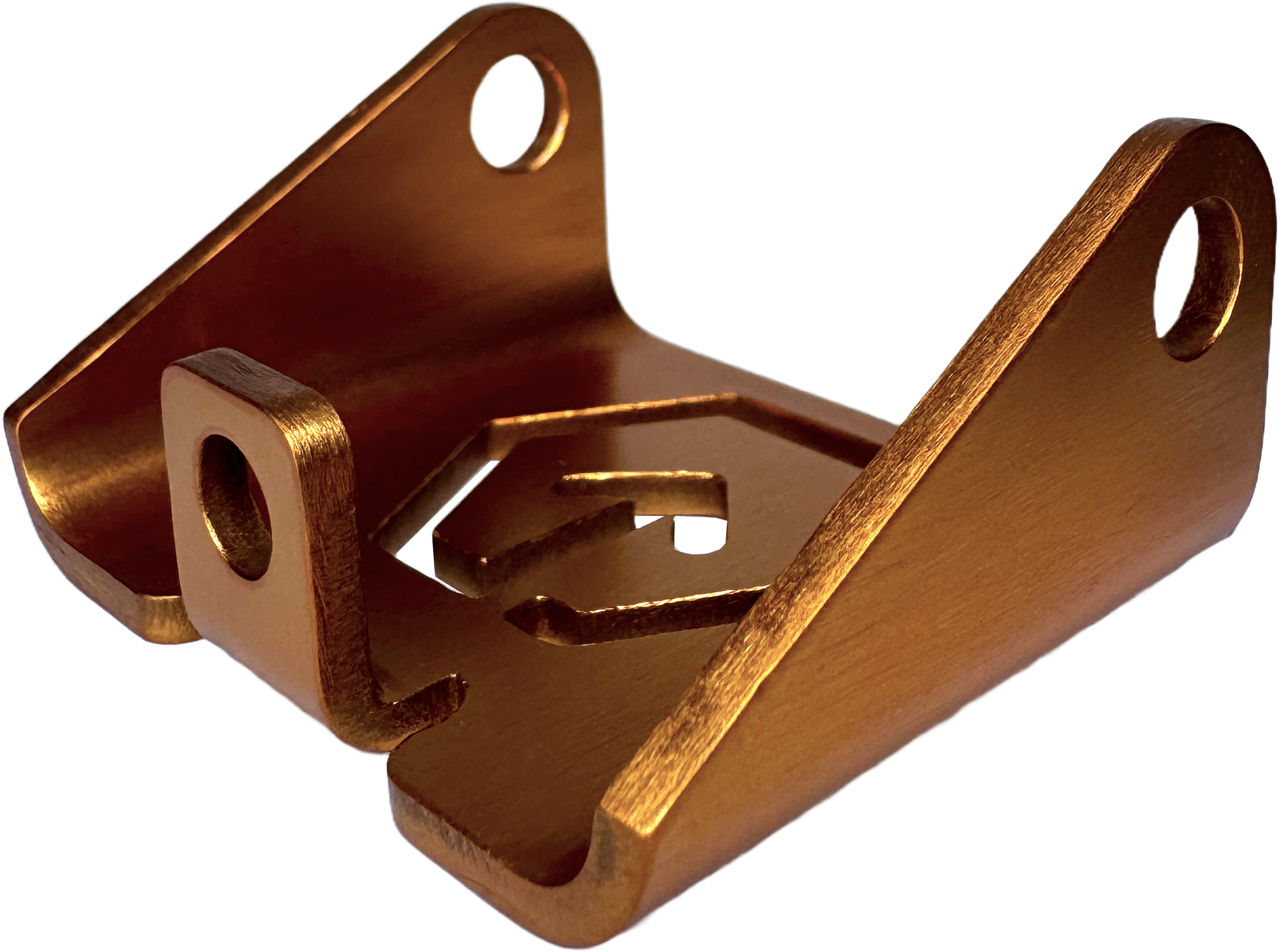

Orange

Provides increased corrosion resistance and improves aesthetic appearance.

More colours available including colour matching

Provides increased corrosion resistance and improves aesthetic appearance.

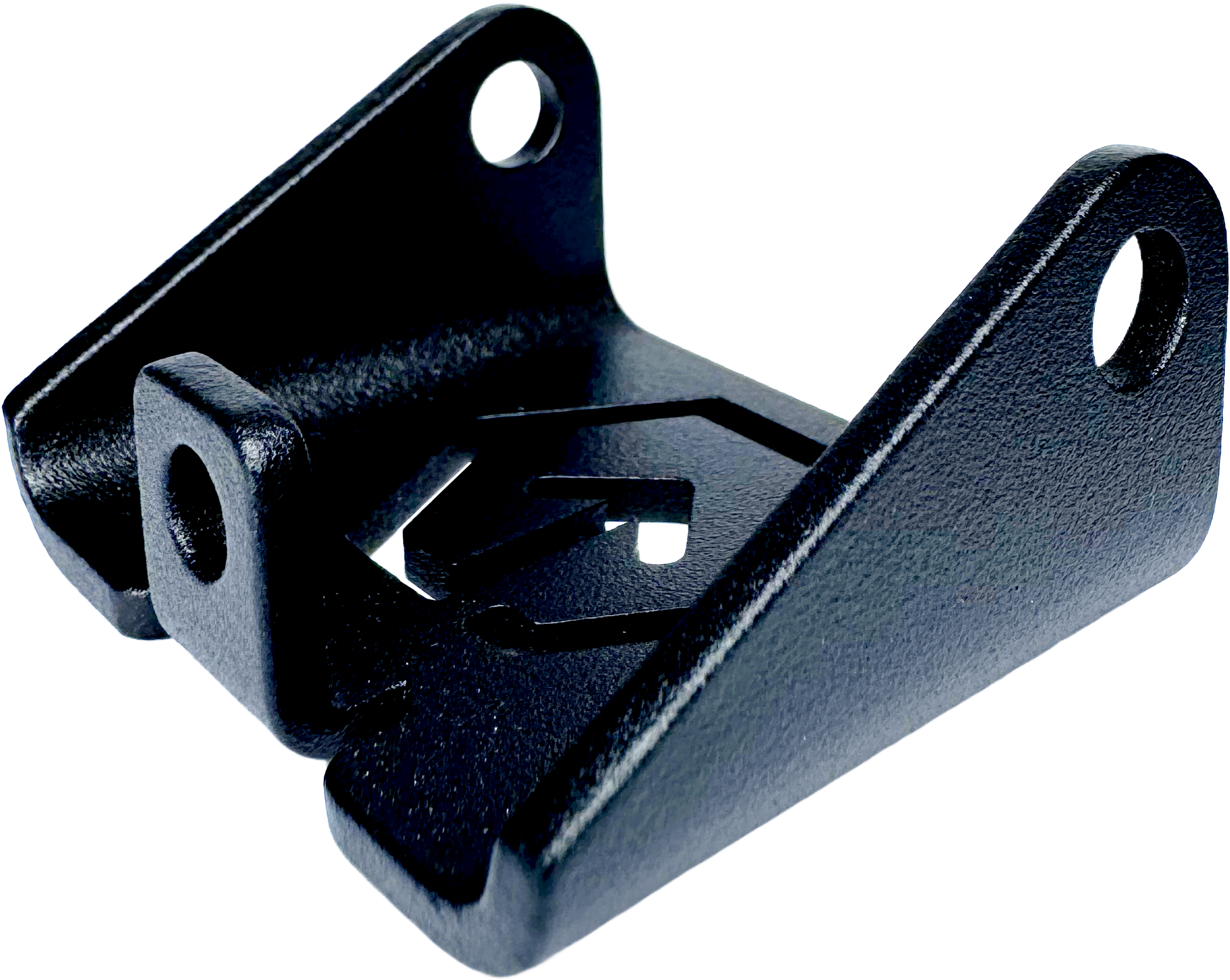

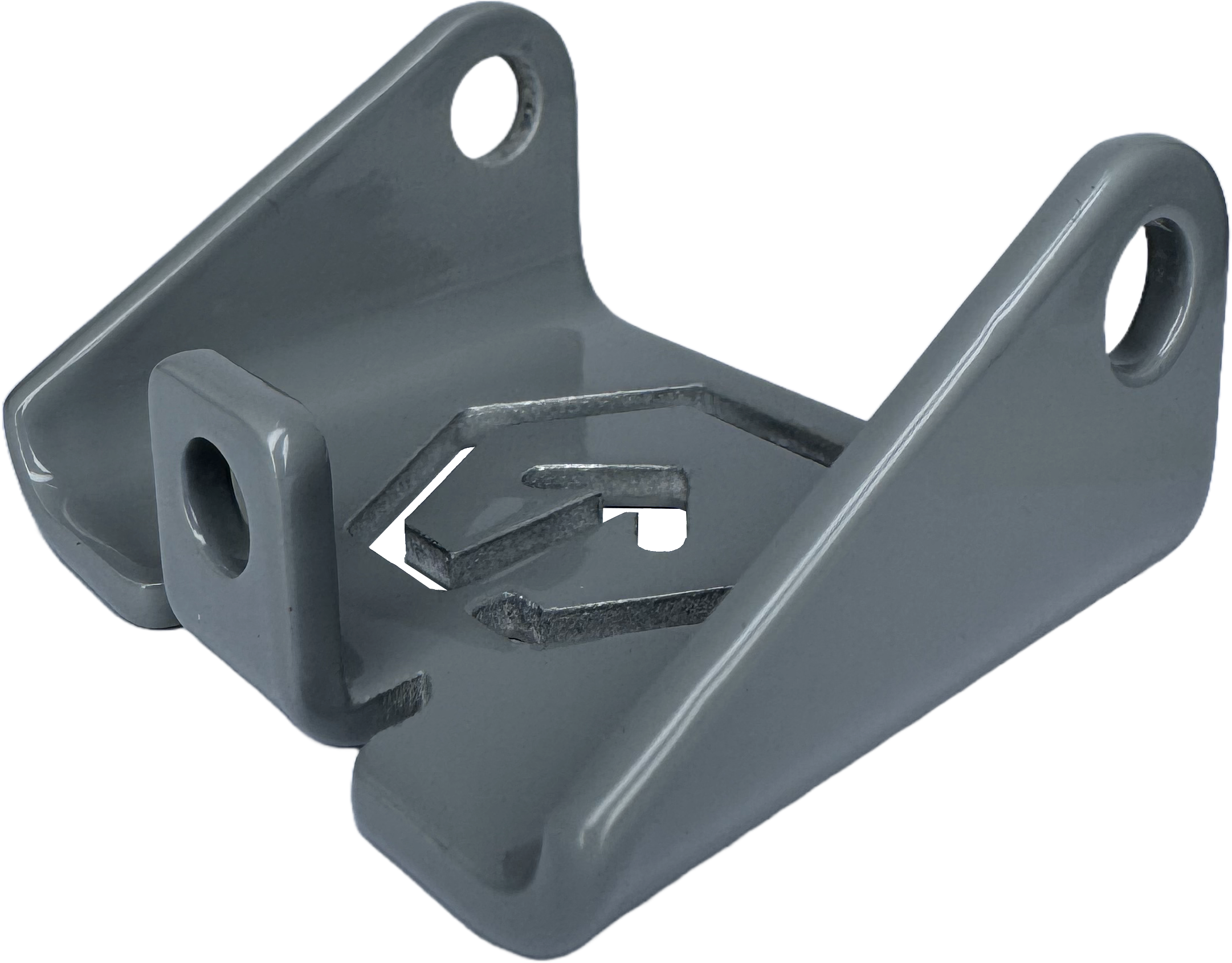

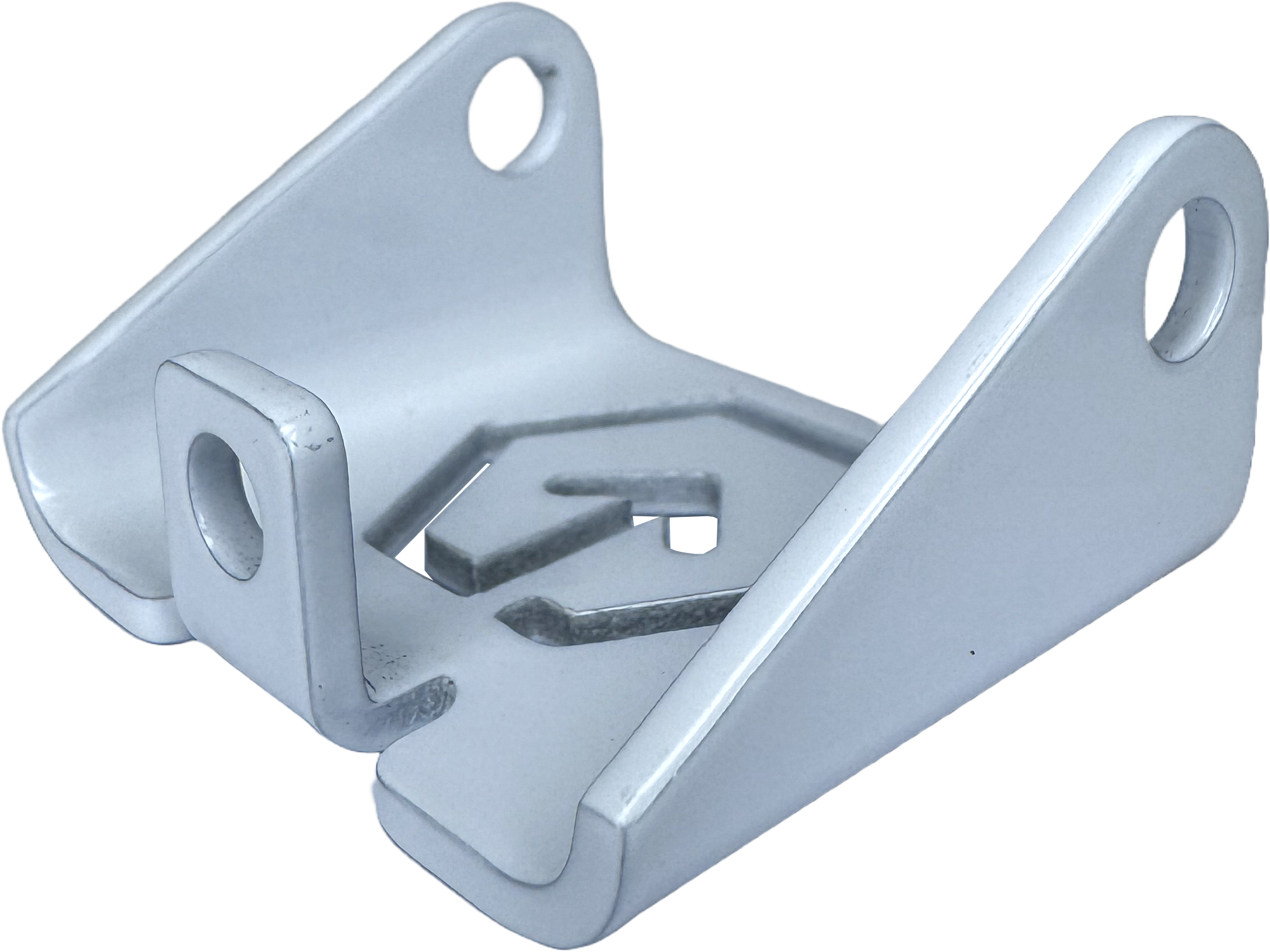

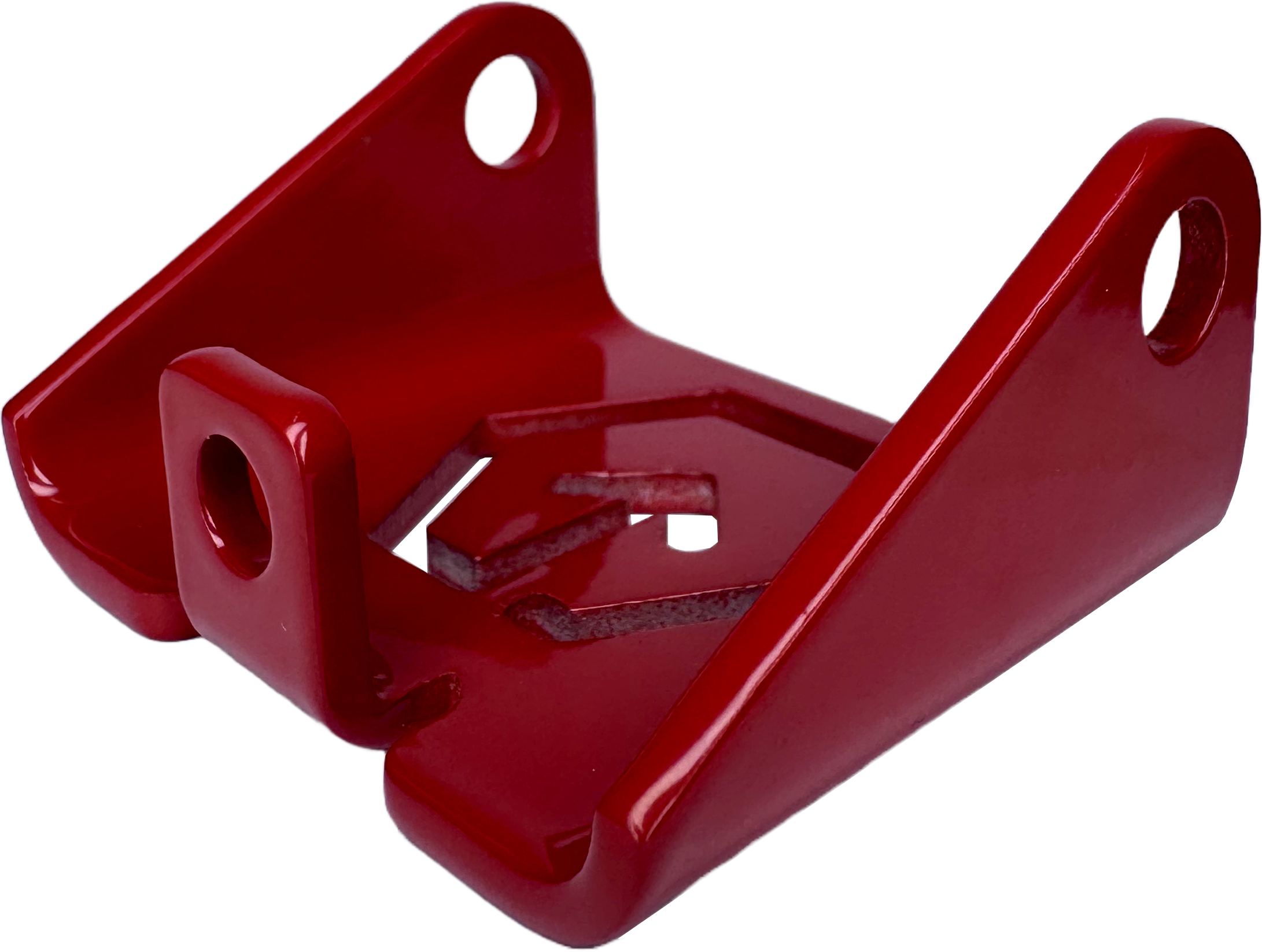

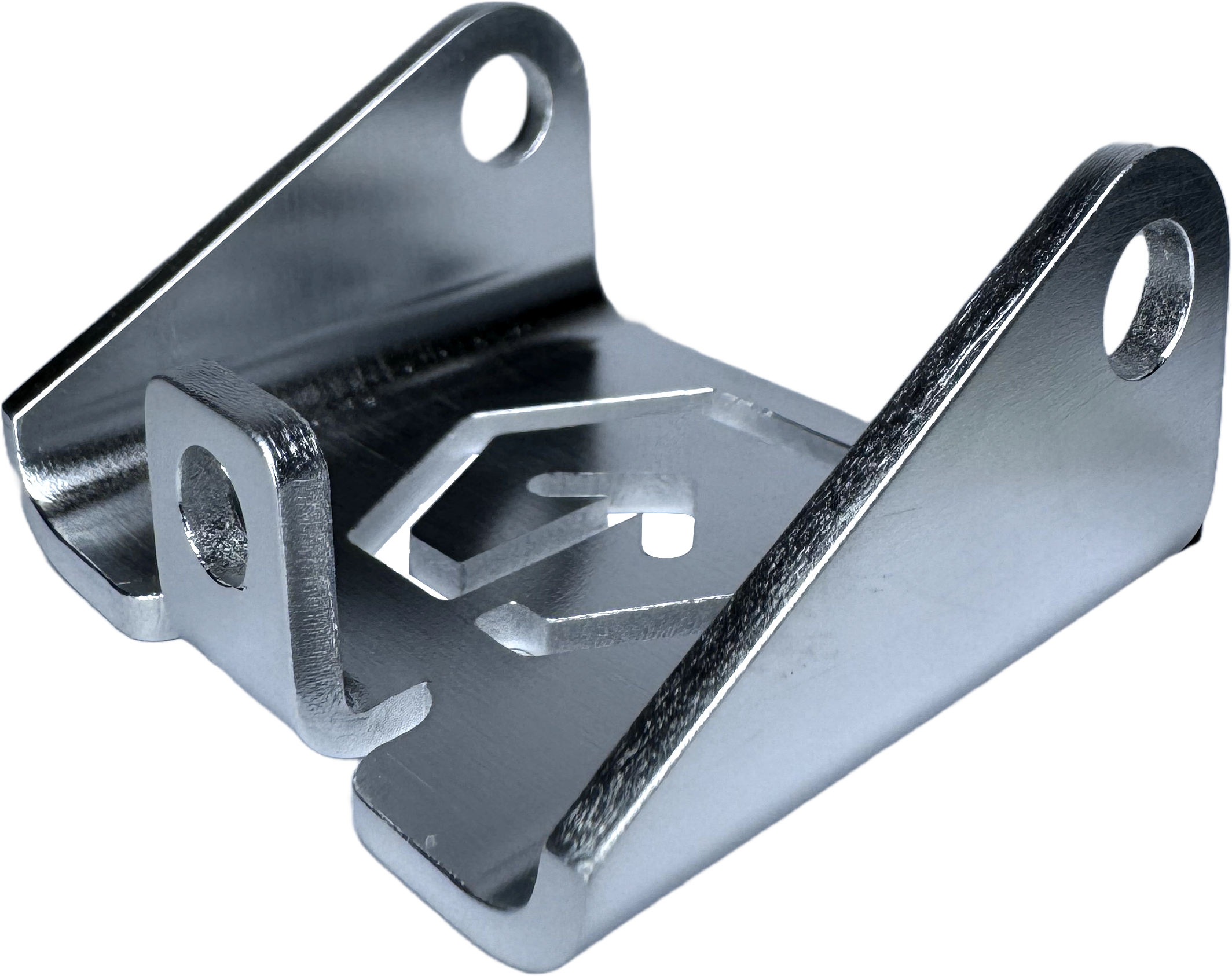

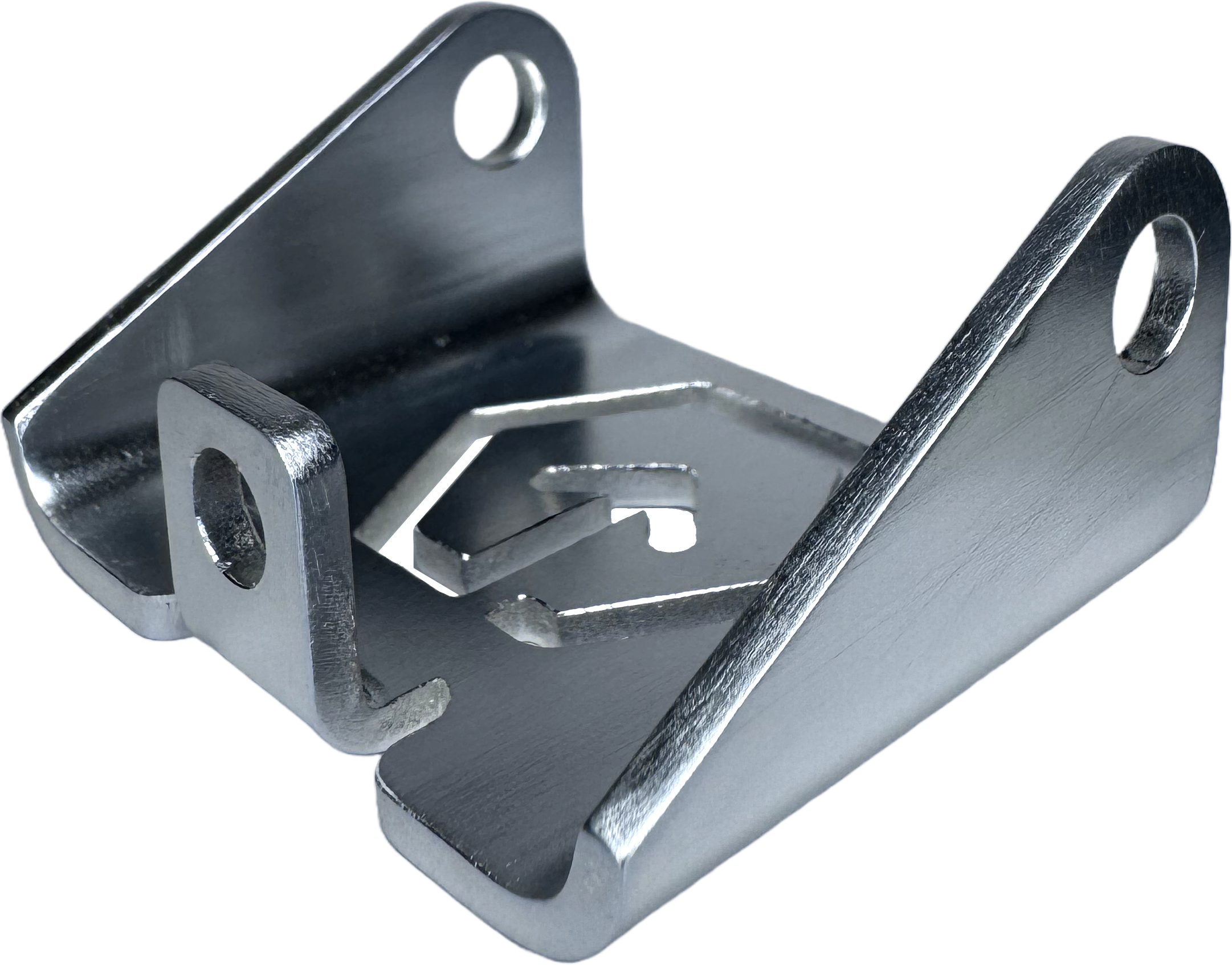

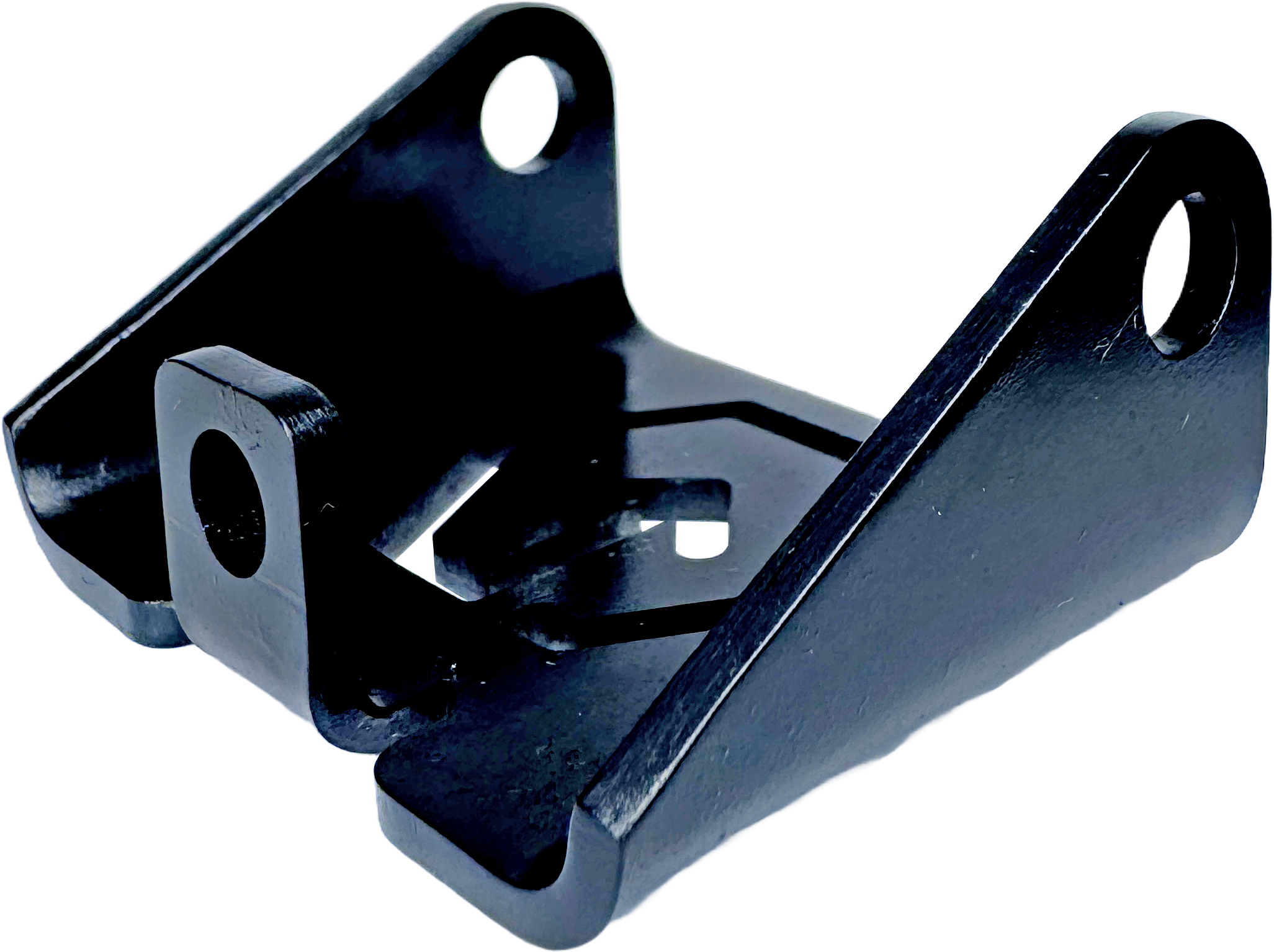

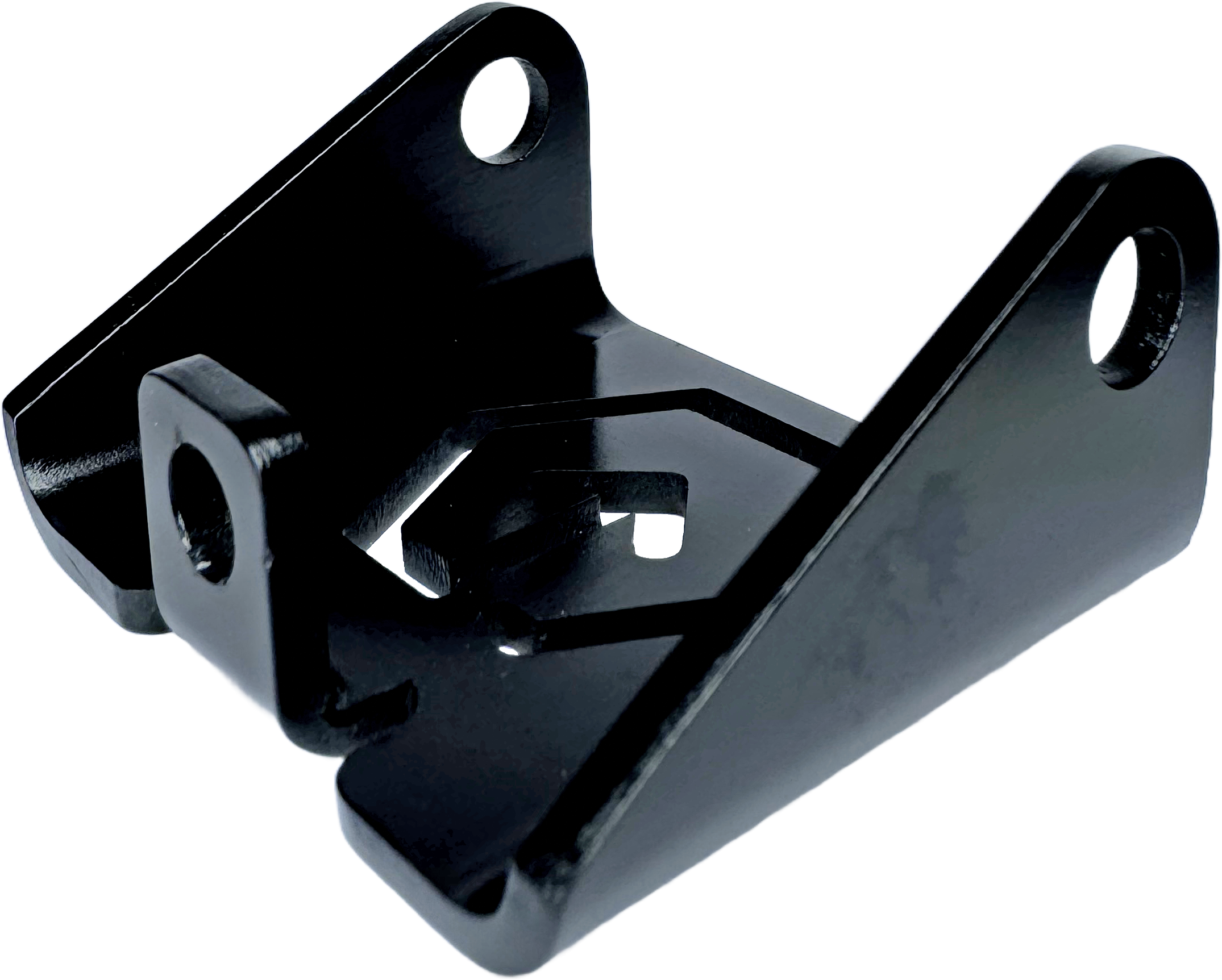

Powder coating is a common finish for sheet metal components due to the continuous and even coating that protects the base material from corrosion as well as improves the aesthetic appearance. All exact match Pantone and RAL colours are available with Powder Coating. Standard thickness ranges are typically between 50µm to 70µm.

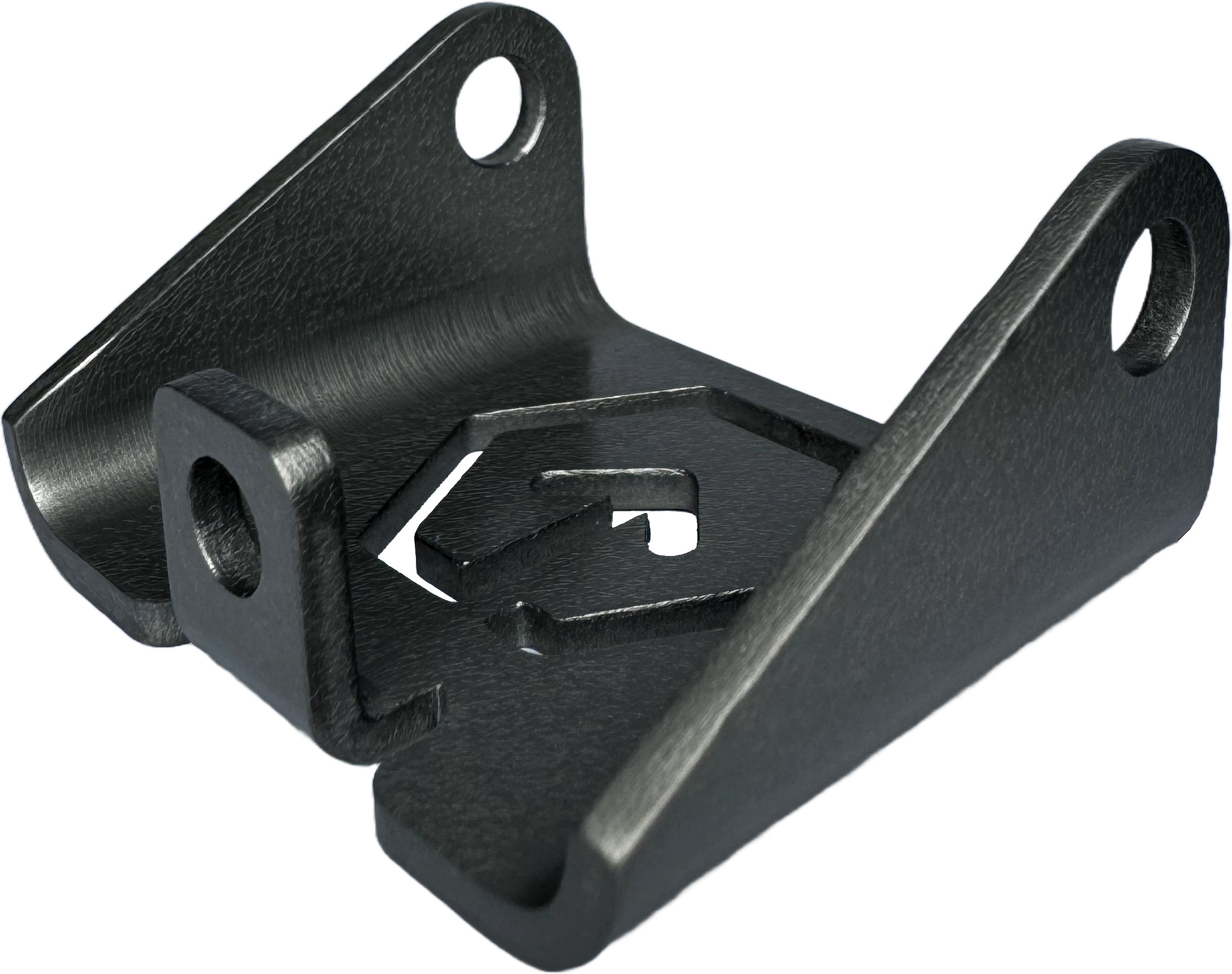

RAL 9005 Black (Matte 30%±5%))

A grainy matte appearance that does not reflect much light.

RAL 9005 Black (Satin (60%±5%))

A smooth surface with slightly reflective appearance.

RAL 9005 Black (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

RAL 9005 Black (High Gloss (80%±5%))

A smooth surface with very highly reflective appearance.

RAL 7004 Grey (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

RAL 9010 White (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

RAL 3001 Red (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

All RAL colours available including colour matching

A smooth surface with highly reflective appearance.

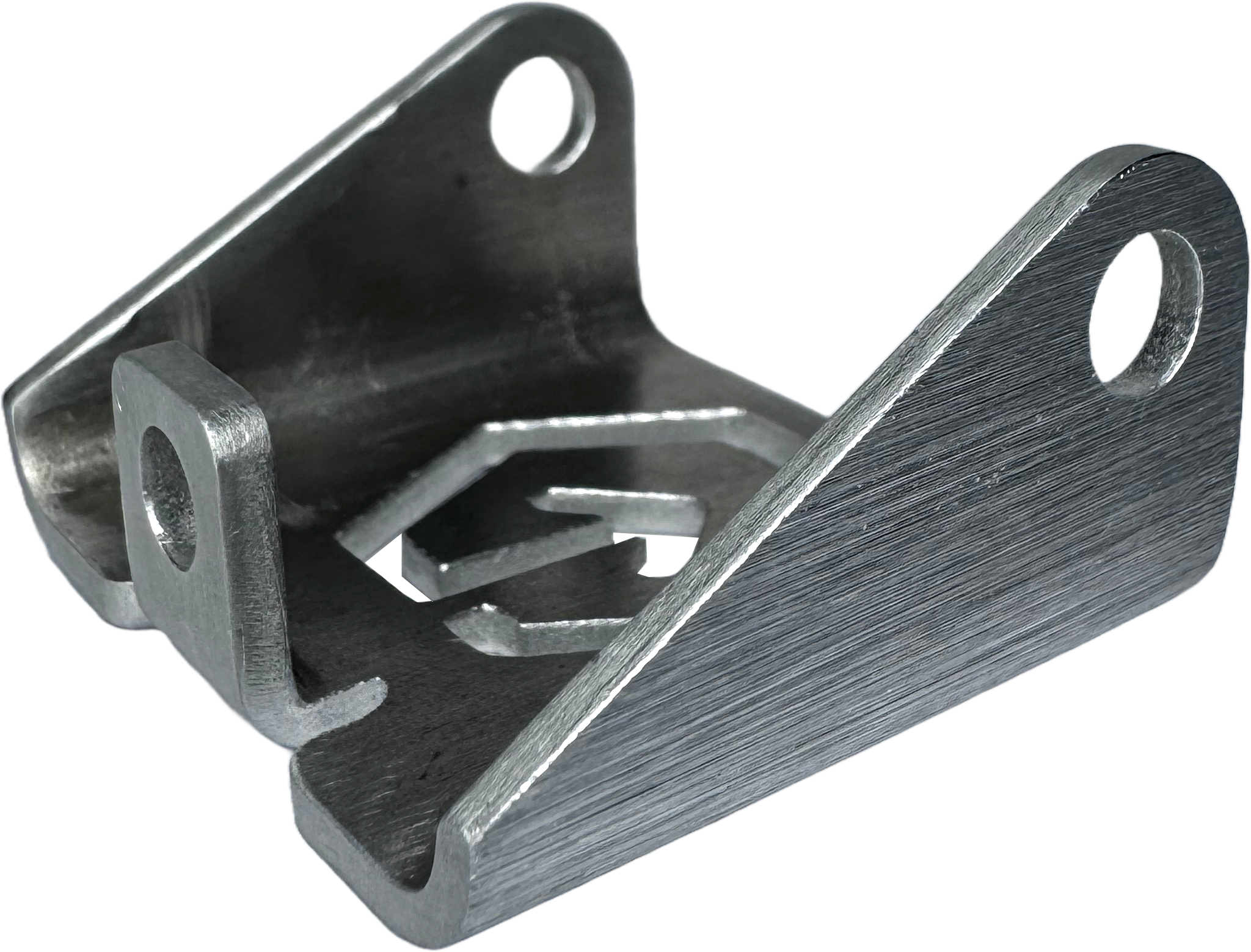

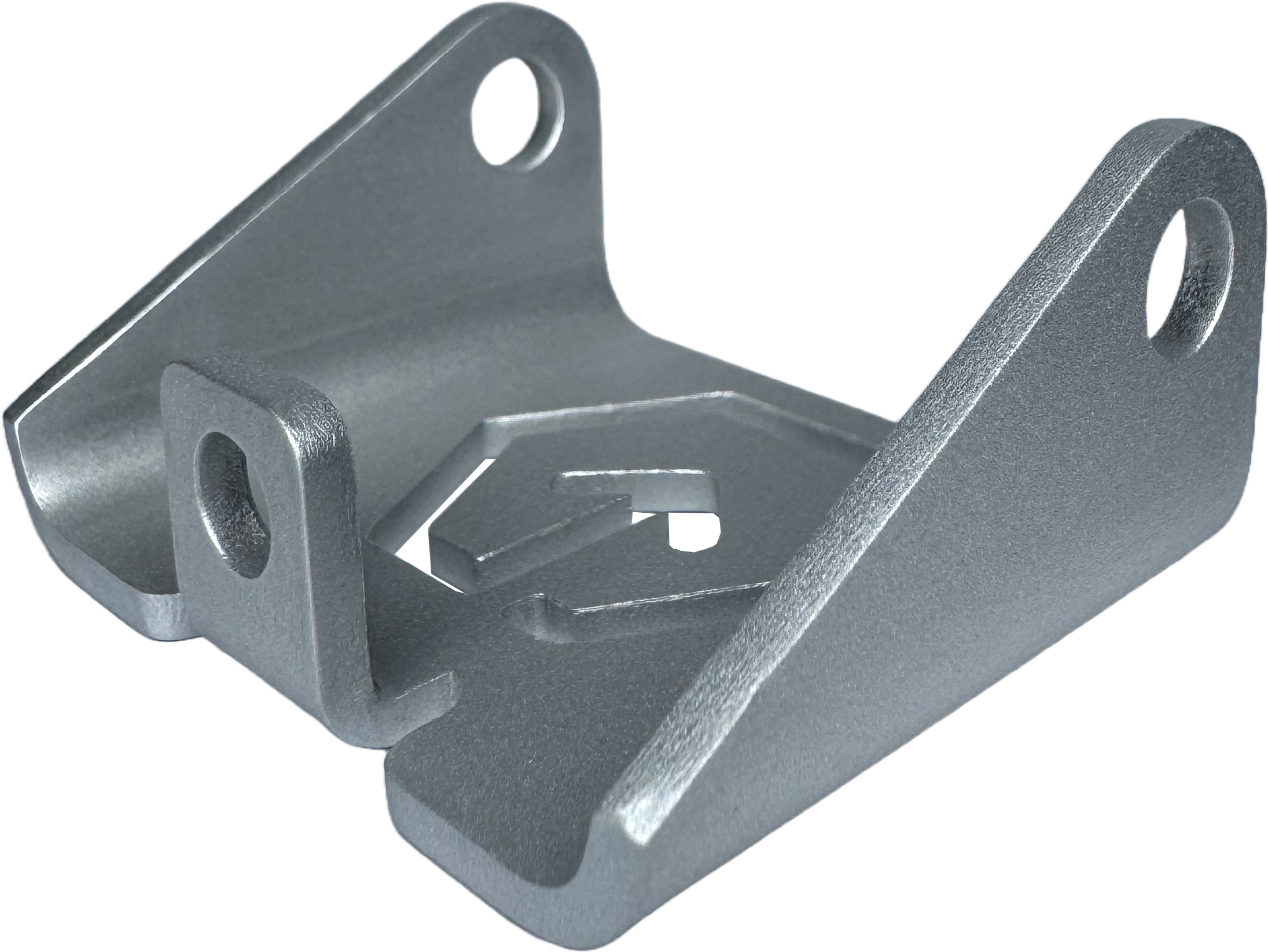

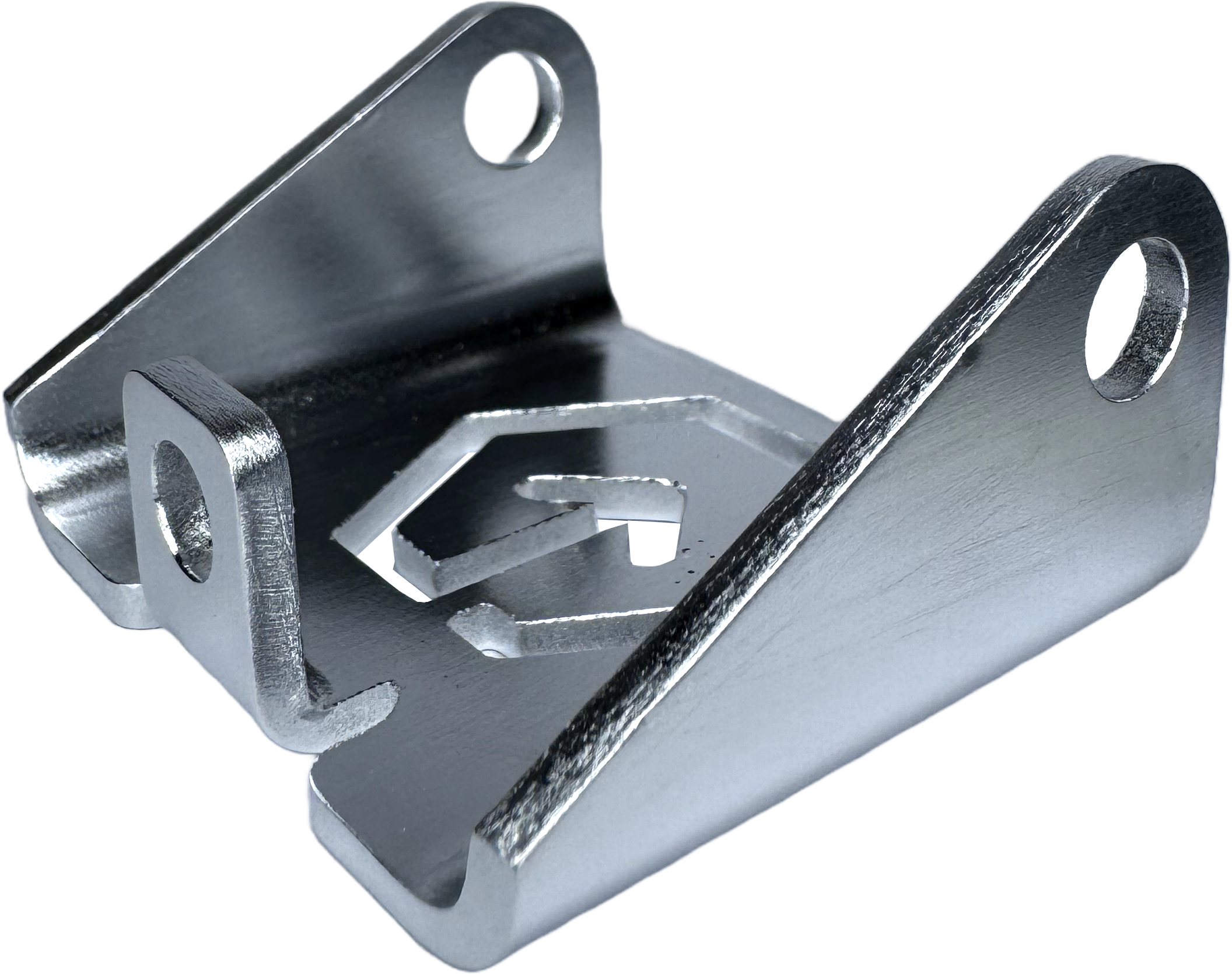

Mechanical finishes are typically for improving aesthetics or preparing a base material for an additional treatment.

Bead Blast

Grainy, slightly matte texture that removes tool marks and light scratches

Mirror Polishing

Hand polished to create high cosmetic mirror-like appearance.

Vibratory Polished

A great way to de-burr and smooth the surface of parts leaving feint grainy lines.

Brushed

A single directional heavy grain is mechanically applied to the material.

Tumbling

A great way to de-burr and lightly polish the surface of parts.

Chemical finishes are used to treat components in bulk, as they are relatively cost effective and cover all surfaces of a component.

Electropolishing

Shiny and smooth surface that also enhances corrosion resistance.

Satin Finish

Grainy, slightly matte texture that removes very light marks and scratches.

Chemically brightened

A reflective and shiny surface that is often used to prepare parts before anodising.

Iridite NCP

Excellent corrosion resistance, adhesion promotion and non-toxic.

Passivating

Excellent corrosion resistance by removing impurities to increase durability.

Chemical Blackening (Black Oxide Coating)

Applies a thin and uniform black finish that prevents corrosion and wear.

Hard anodising is a thicker variant to sulphuric anodising, with the typical thickness between 25 to 60µm thick although it is possible to go thicker than this. Will conform to MIL-A-8625, Type III, Class 1/2.

Black brightened

A slightly crackled smooth surface texture.

Clear Natural

A slightly crackled smooth surface texture with grey appearance.

Matte Black

A slightly crackled grainy and pitted surface texture.

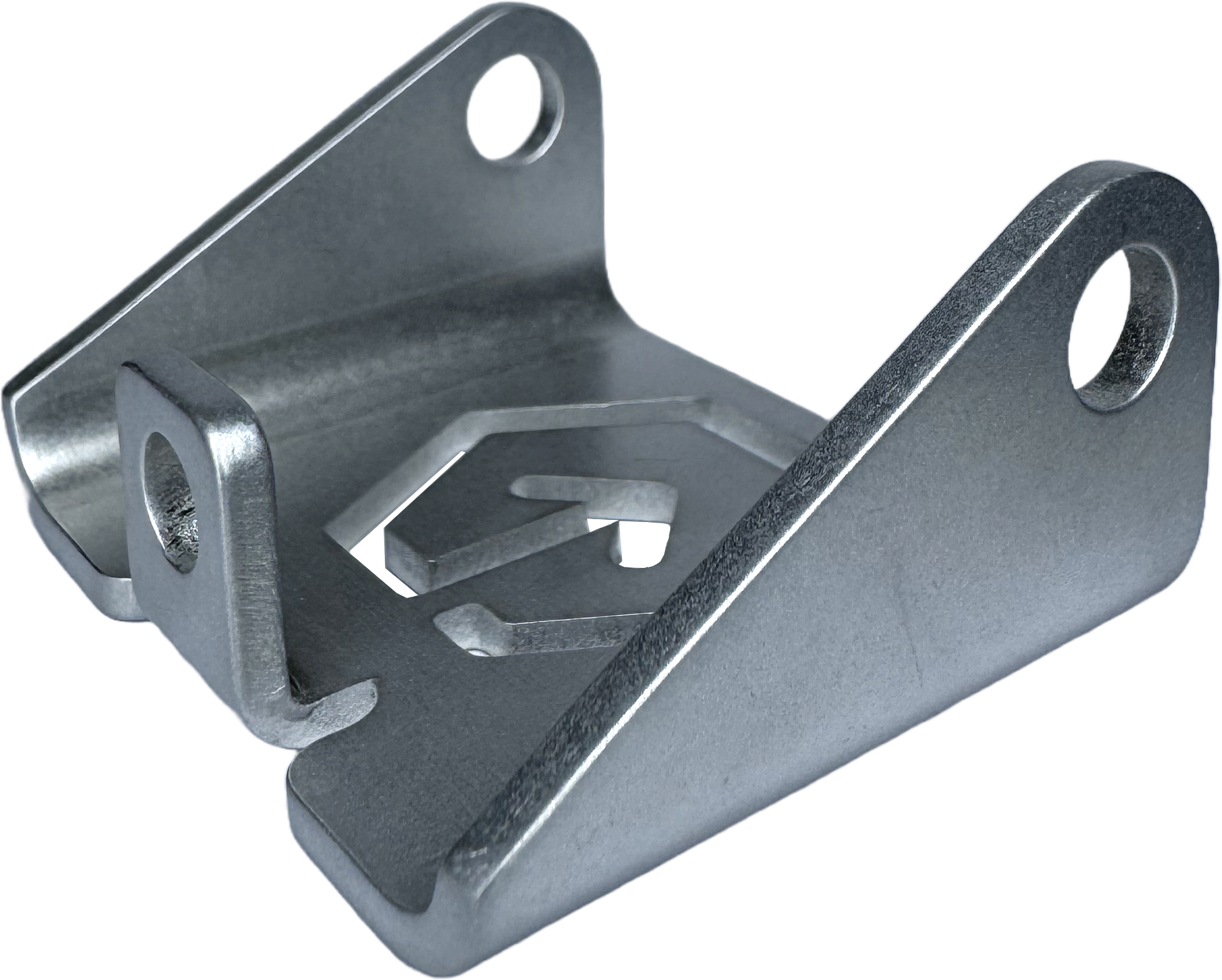

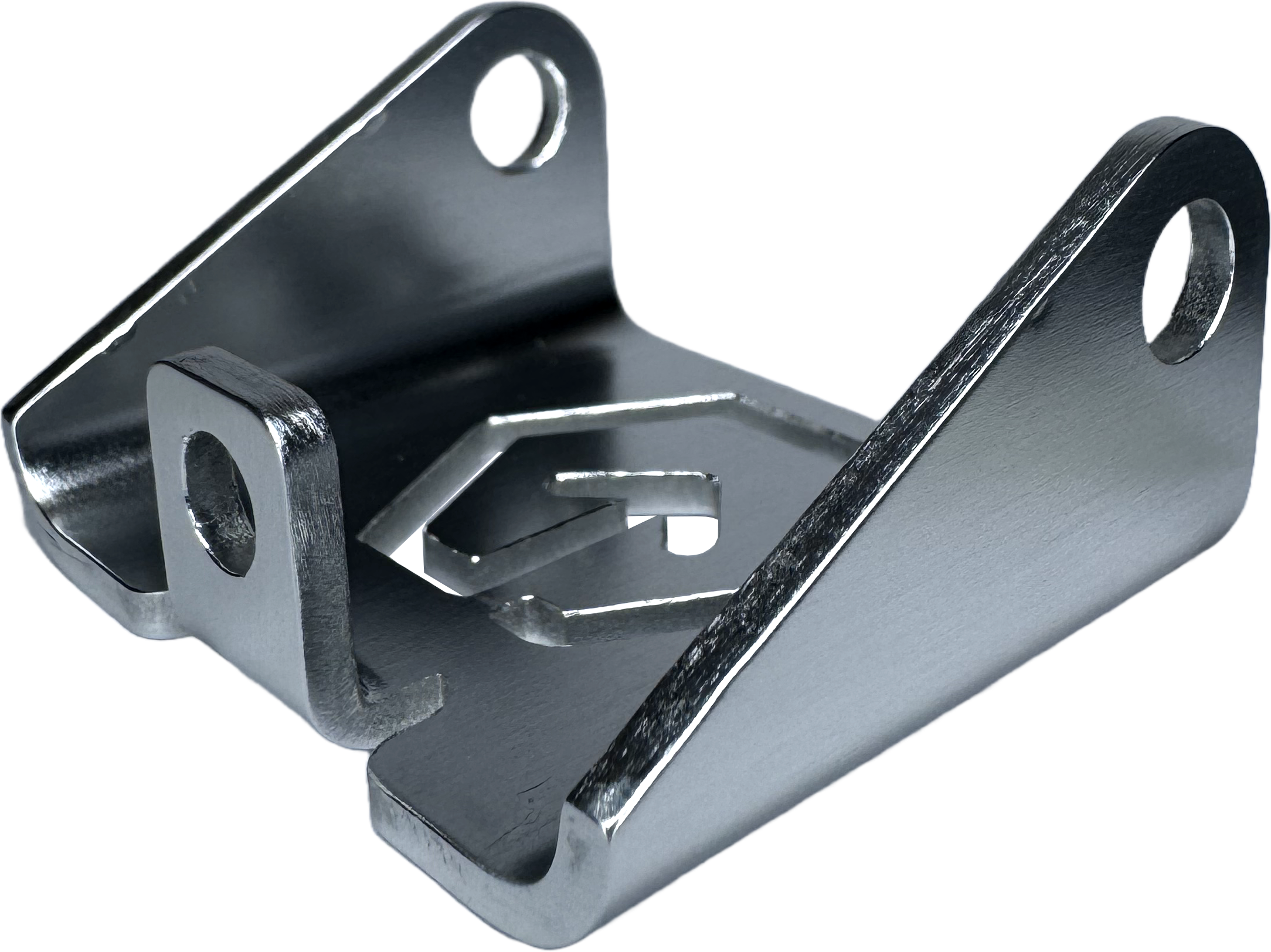

Metal plating provides a uniform thickness coating, which offers protection from corrosion, oxidation and wear. Parts will appear brighter than in photos and are reflective. Plating thickness ranges are typically between 10µm to 25µm depending on the type of plating.

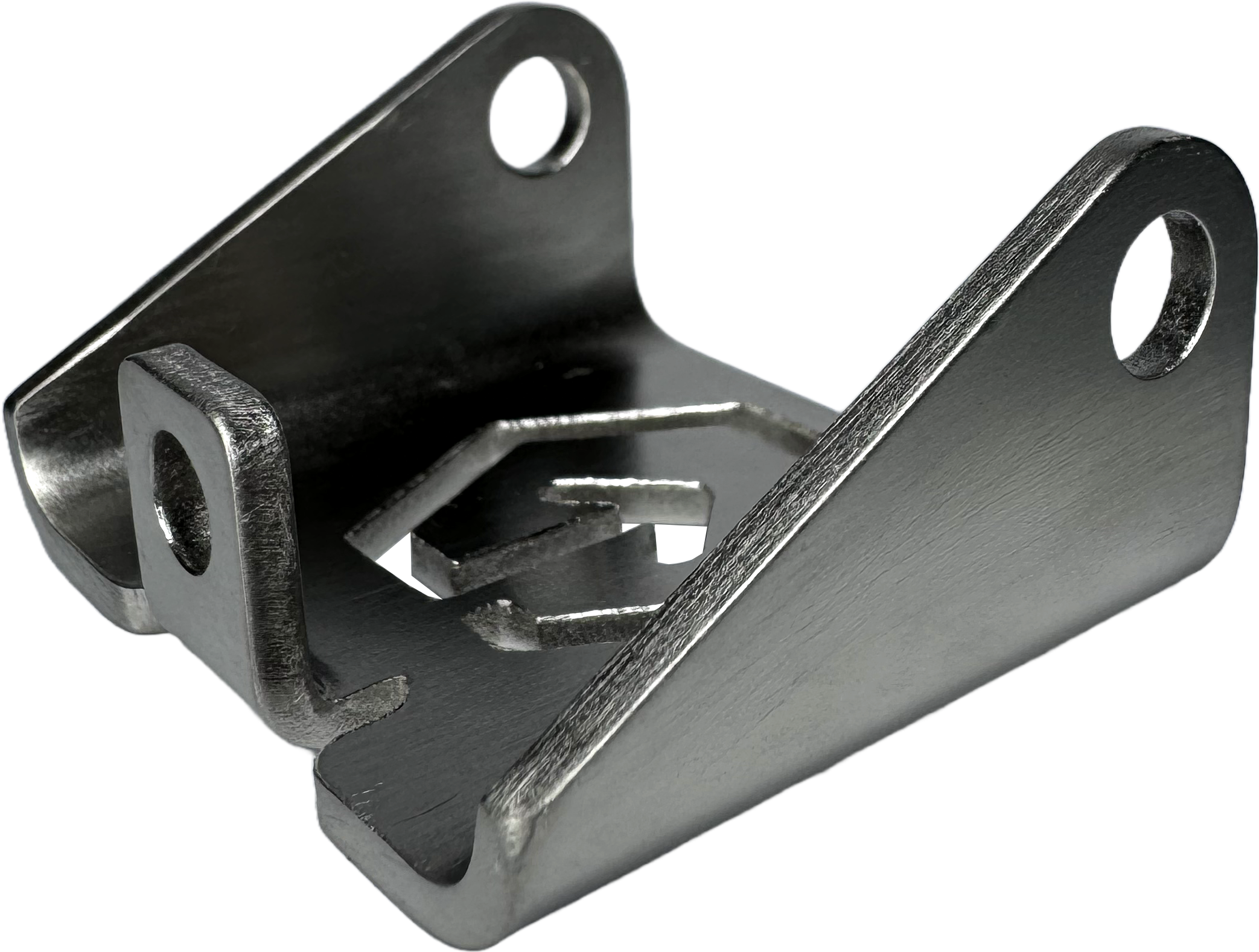

Electroless Nickel Plating

Excellent for corrosion resistance, very cost effective. Has slight reflective surface.

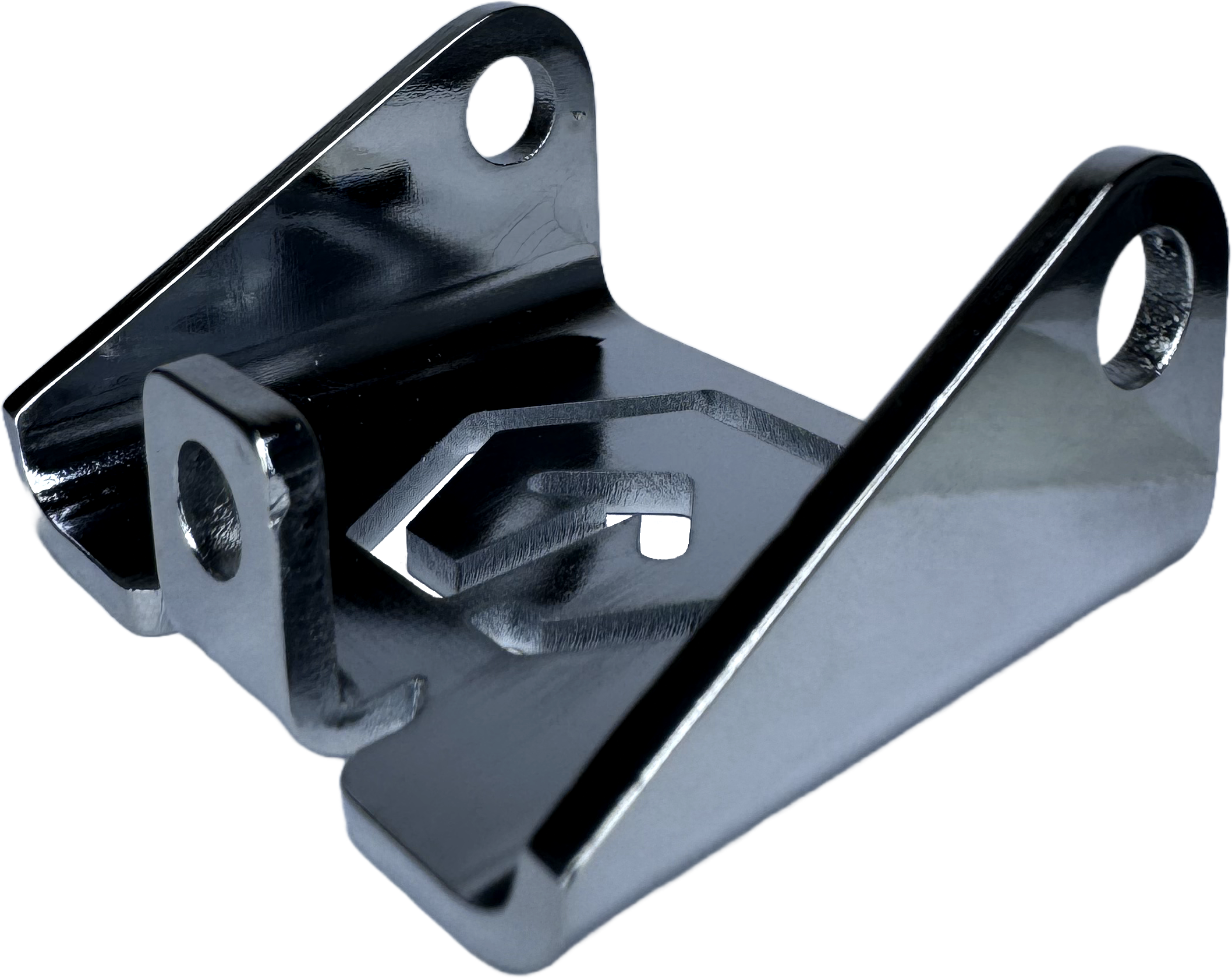

Chrome Plating

Highly reflective and evenly applied surface finish, similar to mirror polish.

Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Jamie Fairclough

Design Lead

Industrial Robotics | Arrival

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

James Batstone

Future Product Research Lead

Brompton Bikes

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

Alex Leck

Design Engineer

JCL Lighting

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

All uploads are secure and confidential.