Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

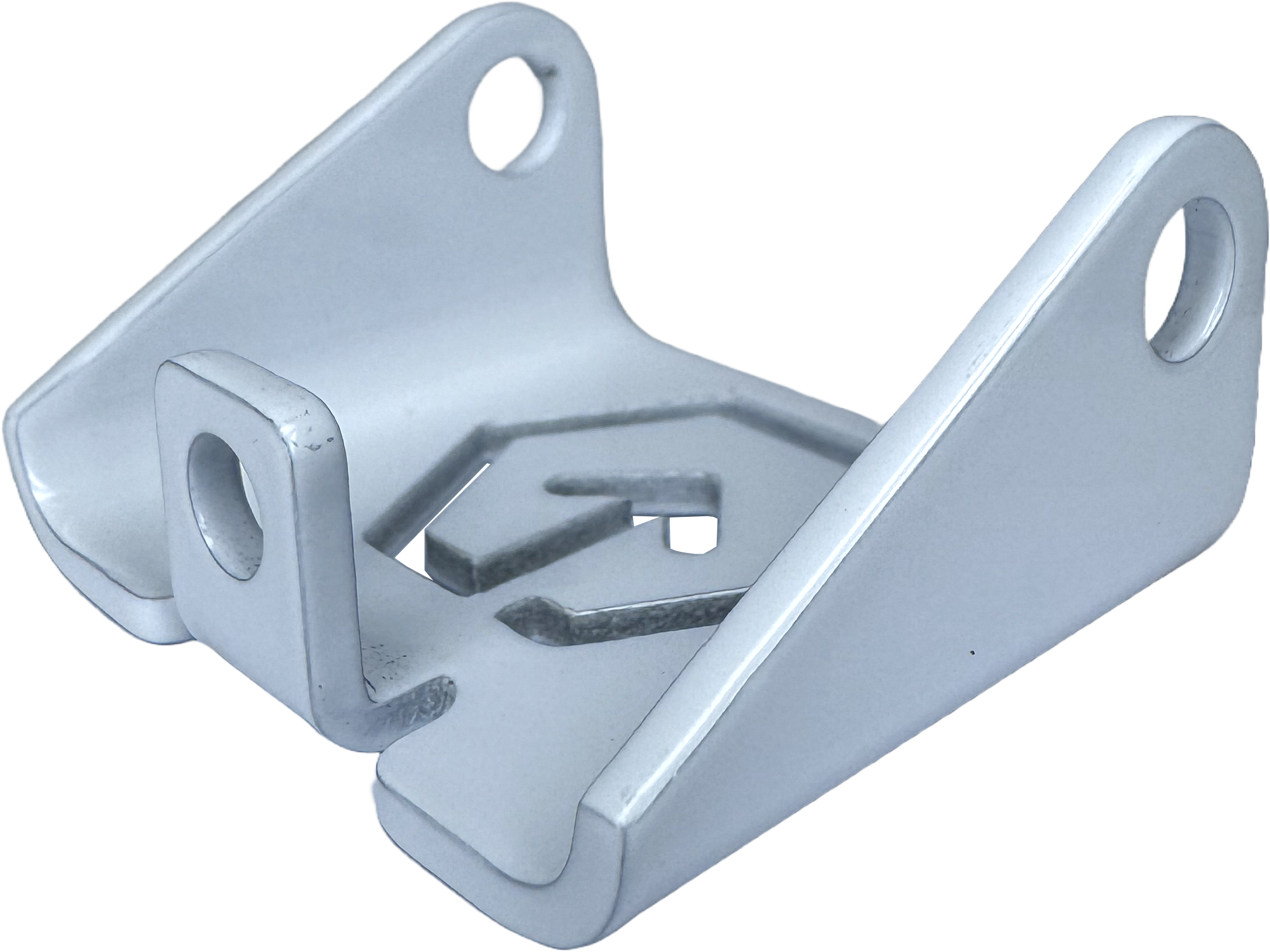

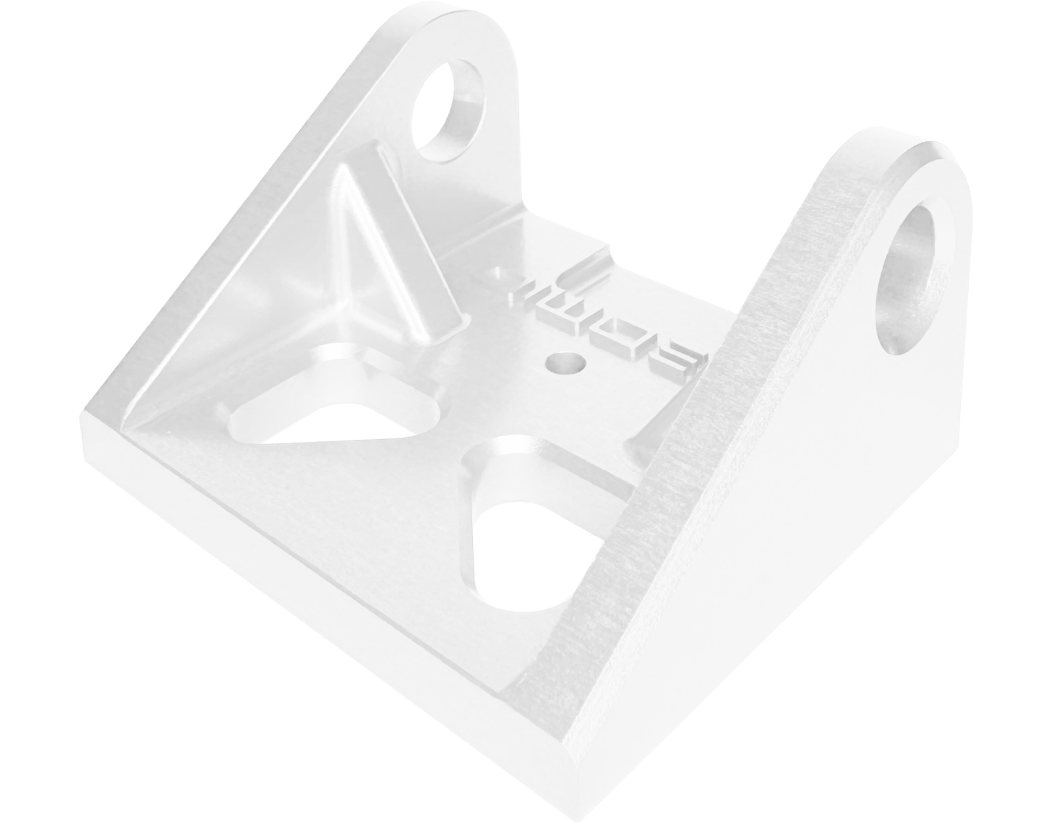

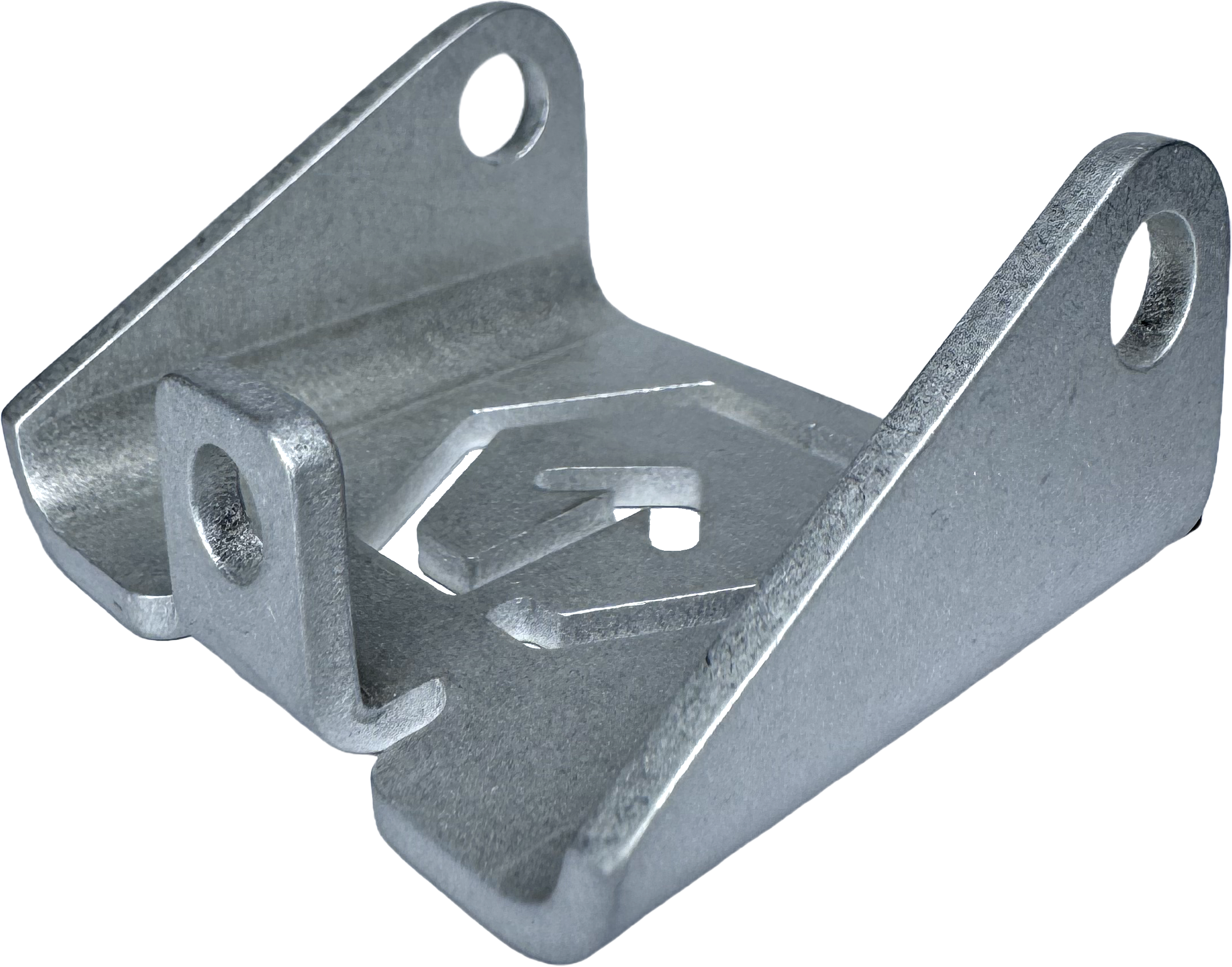

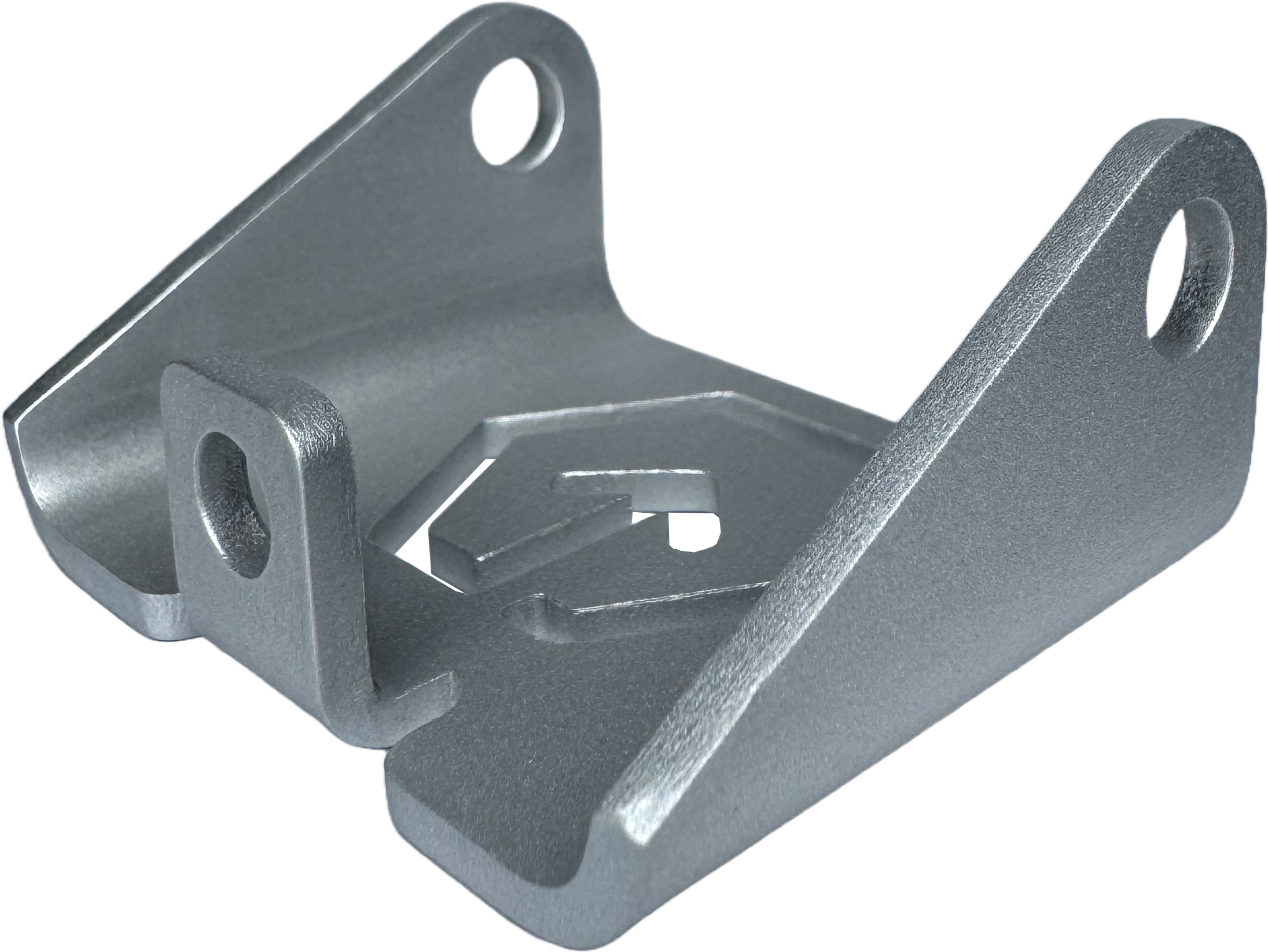

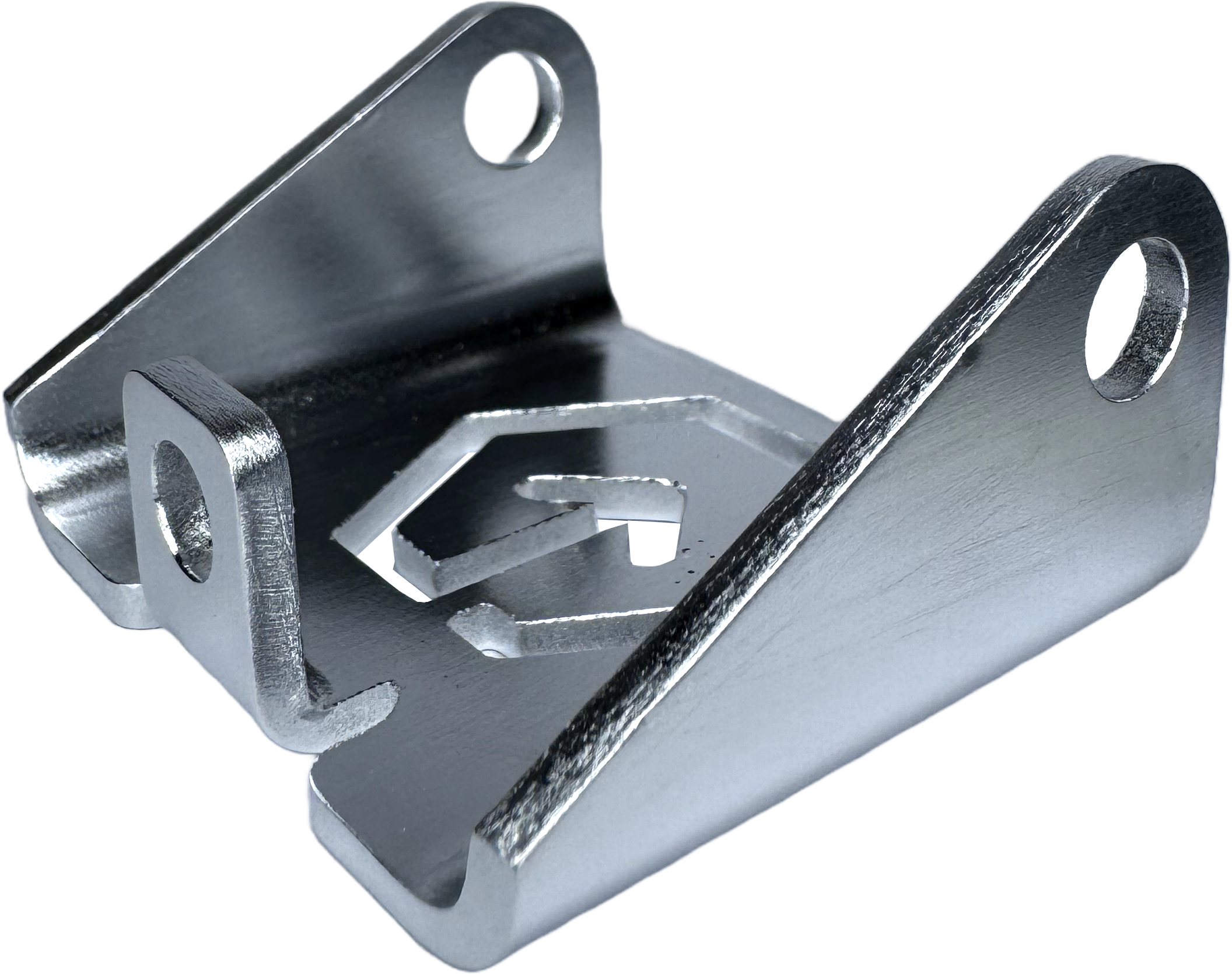

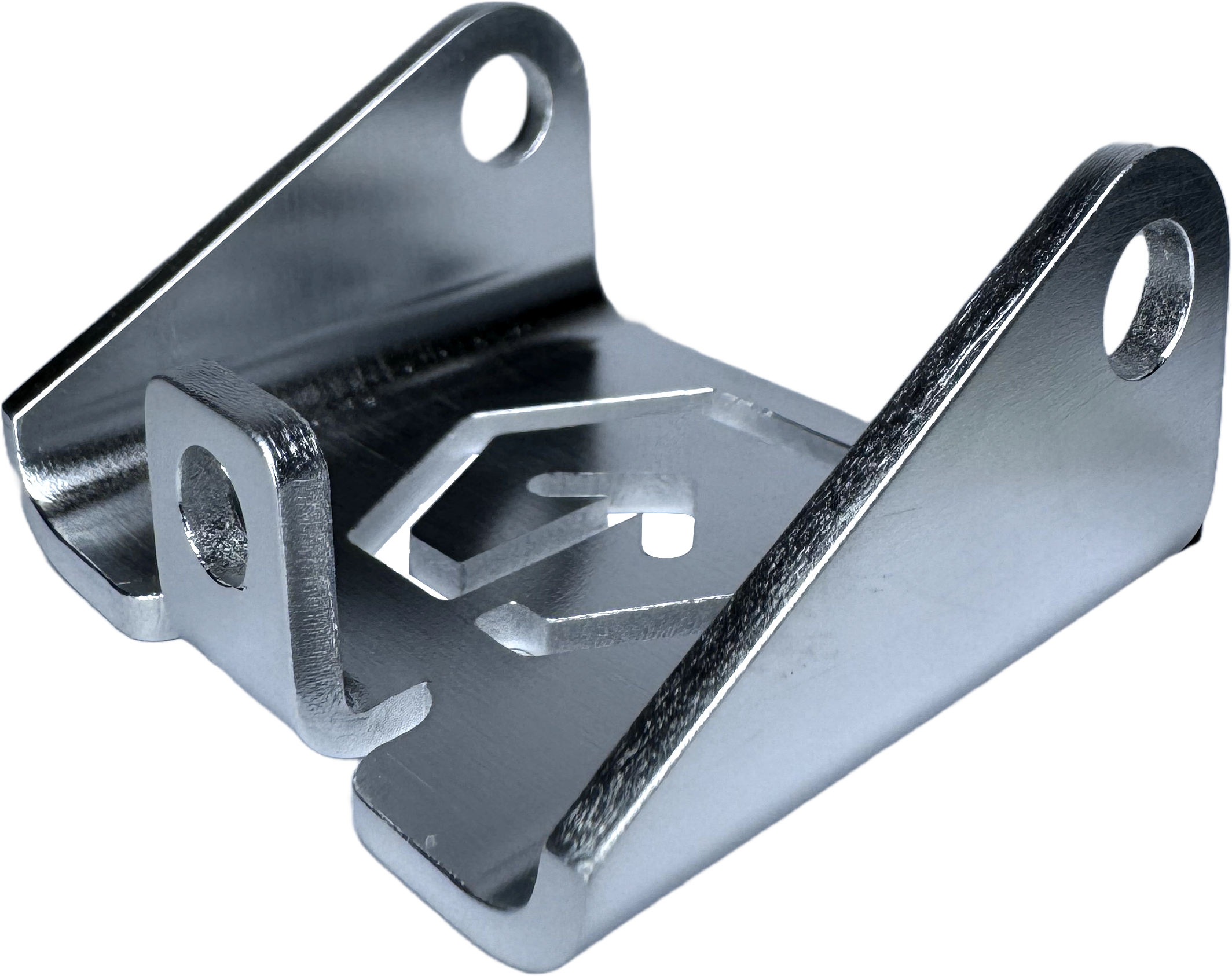

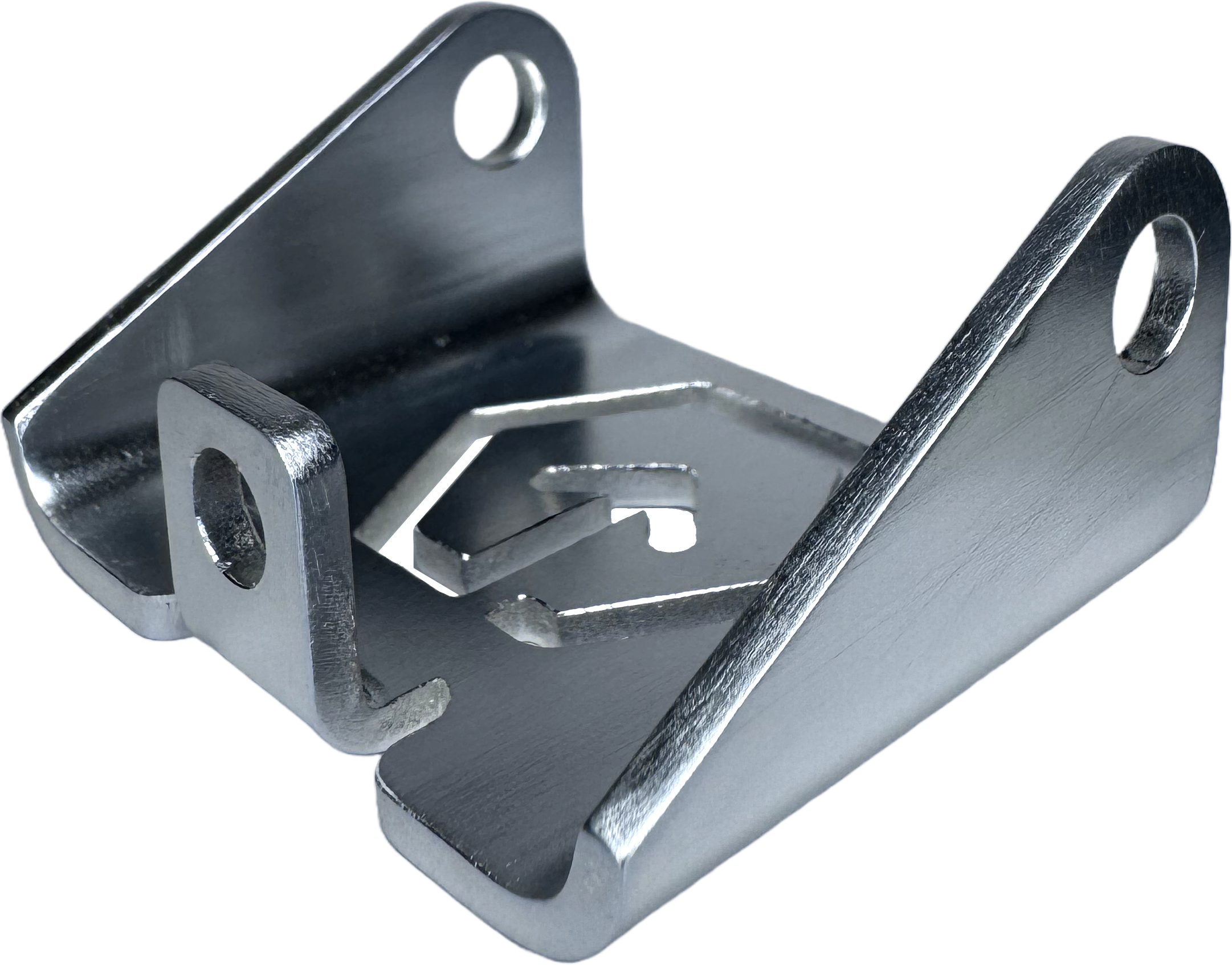

Delivering Sheet Metal parts worldwide in as little as 5 days. Whether you’re looking for low or high volume parts, our sheet metal fabrication services have you covered.

All uploads are secure and confidential.

Trusted by

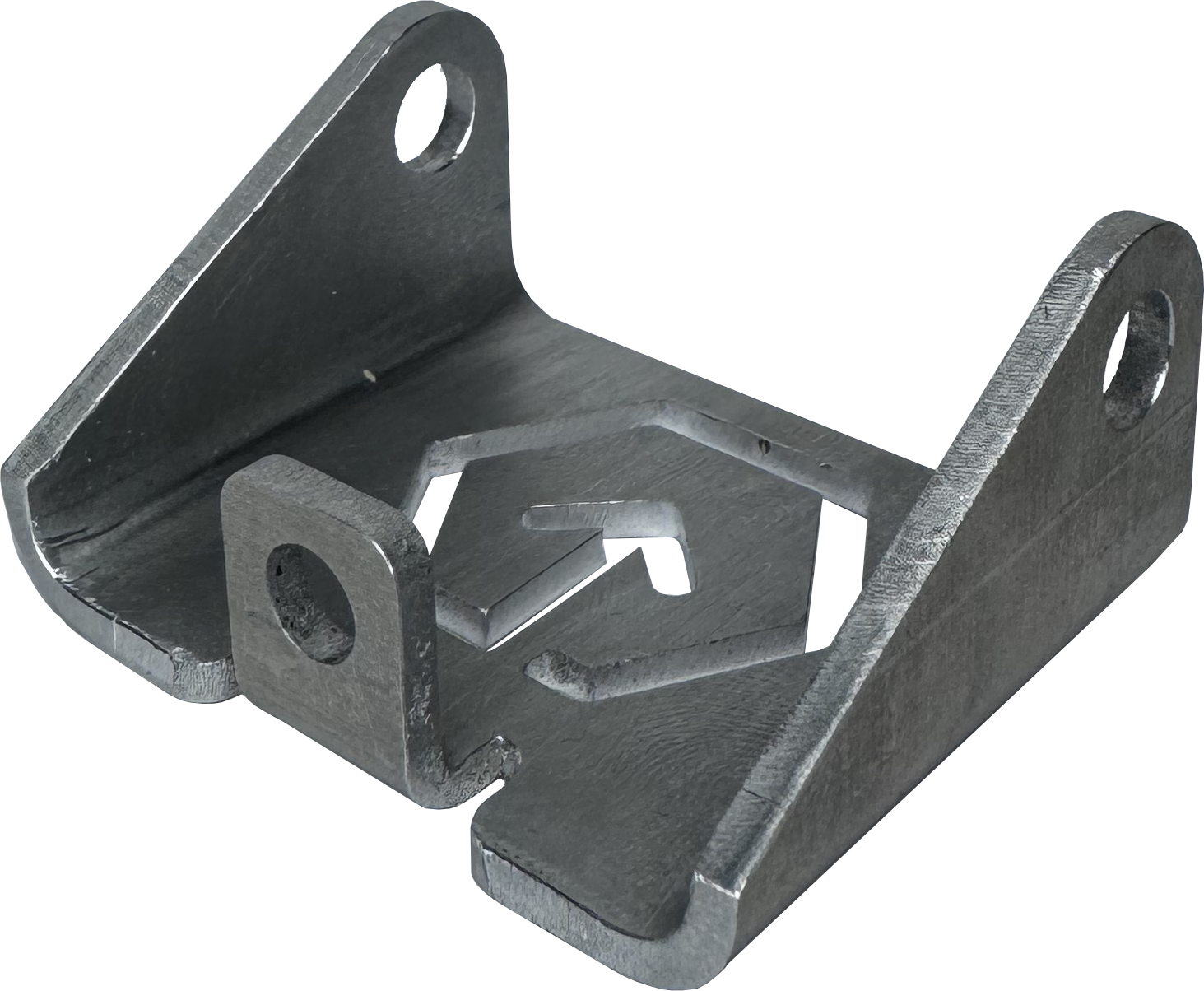

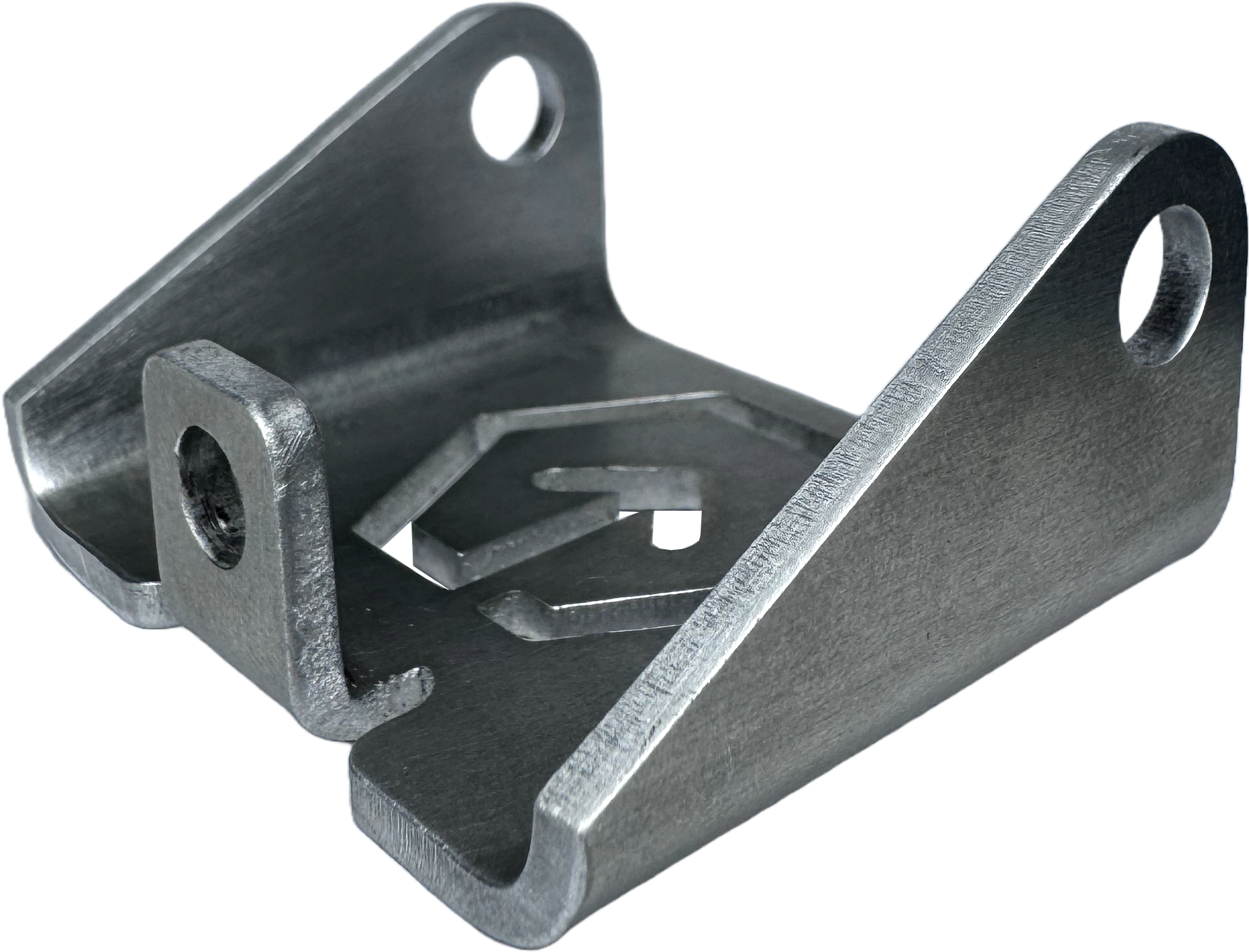

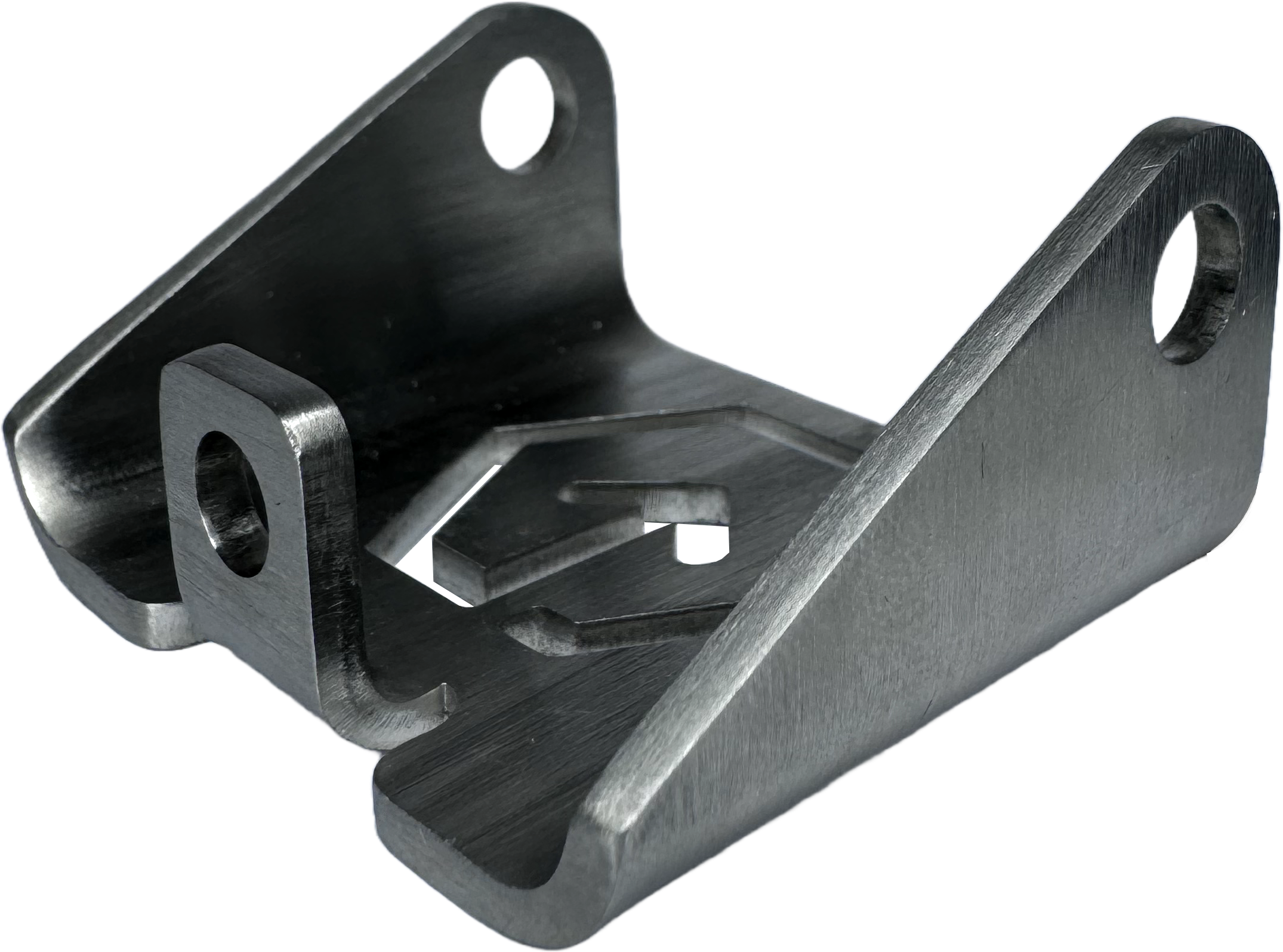

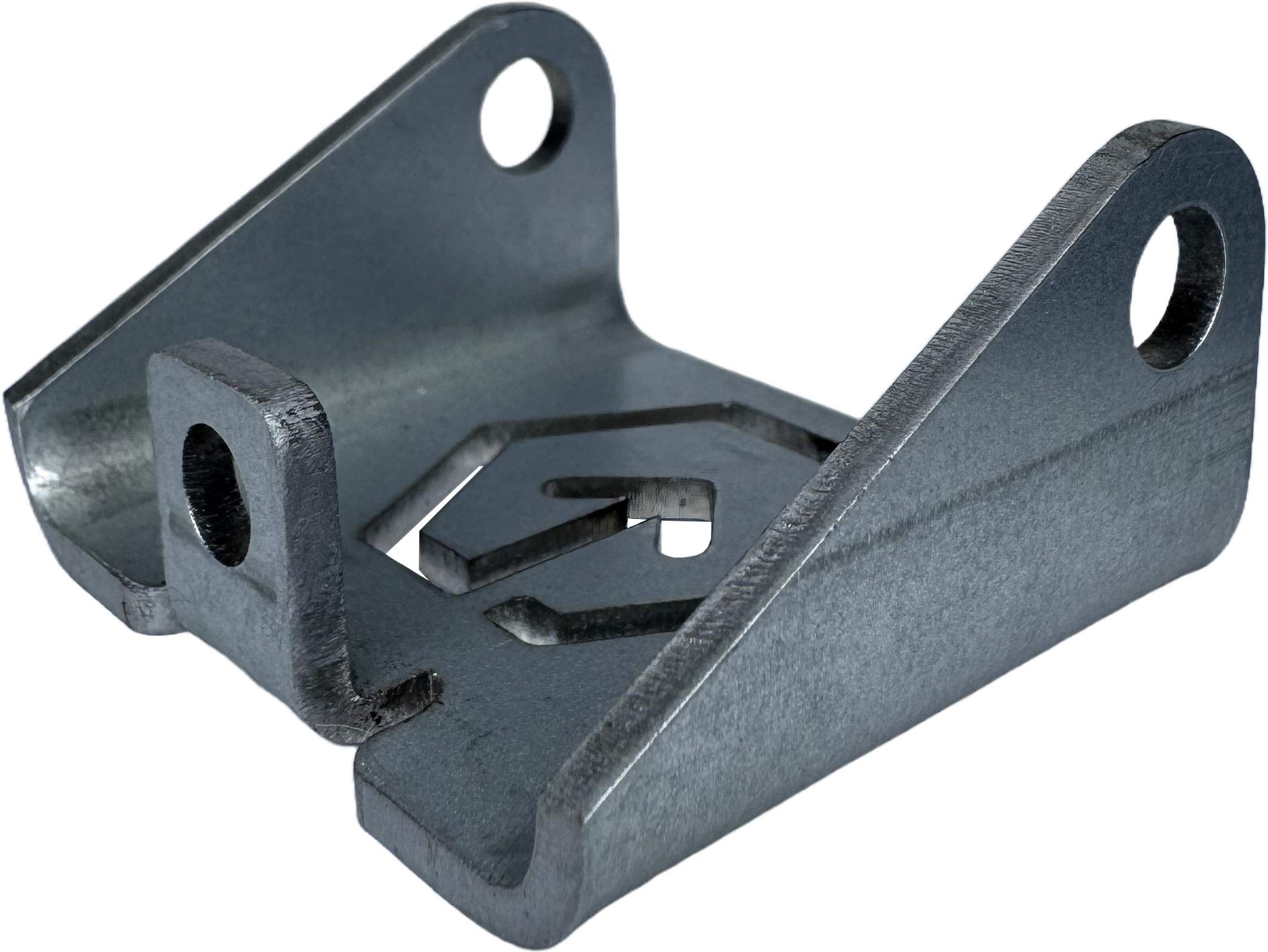

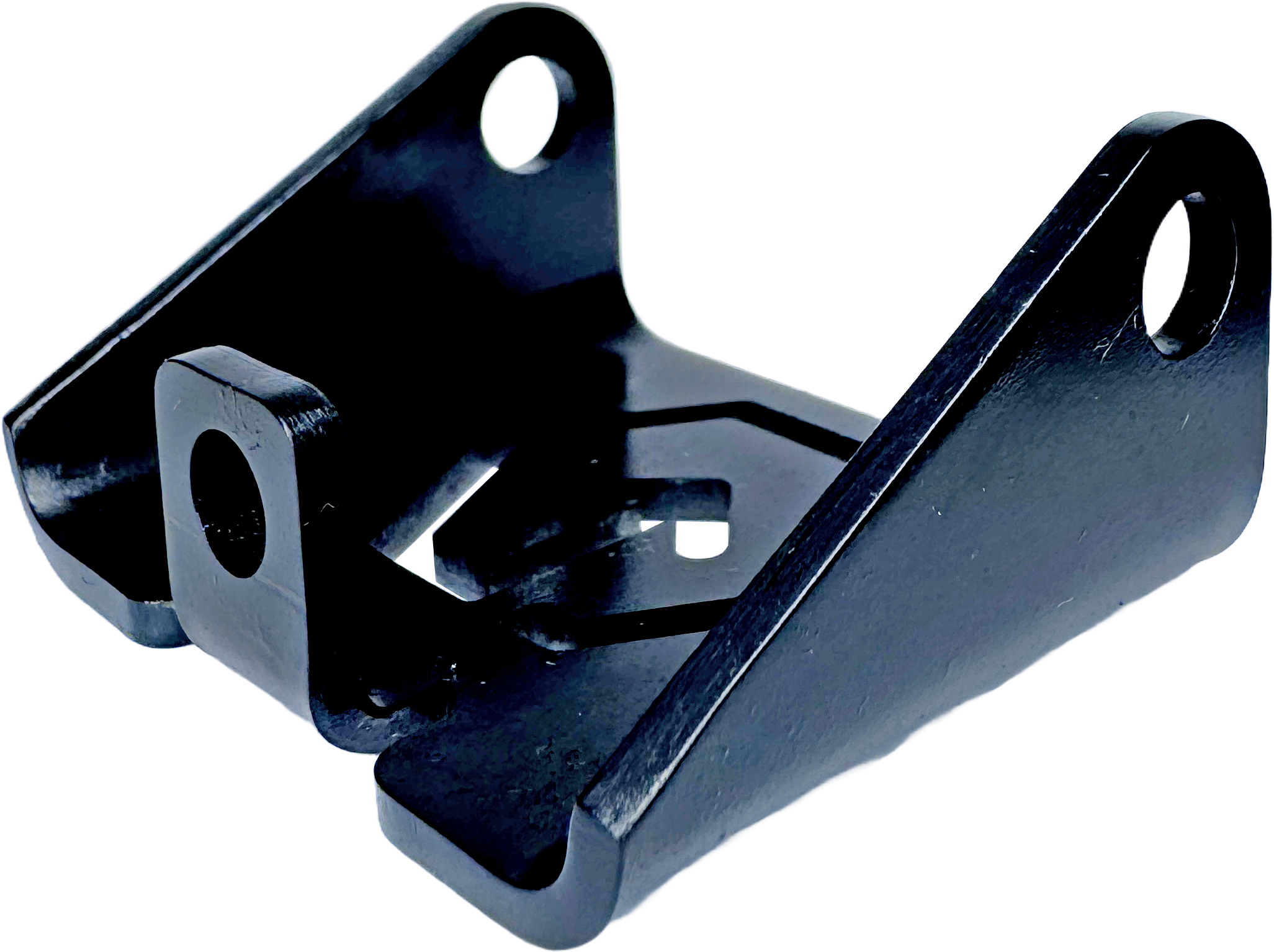

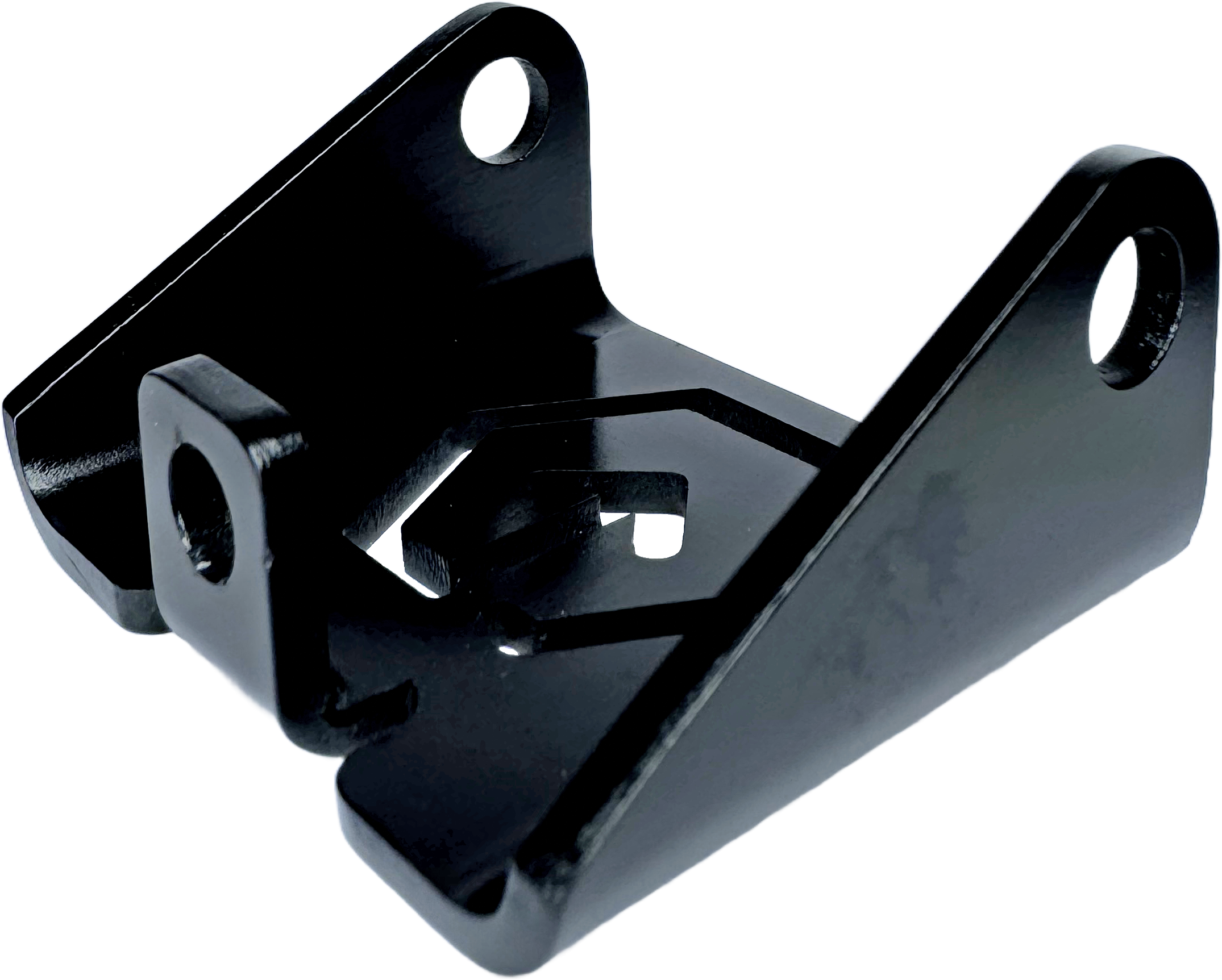

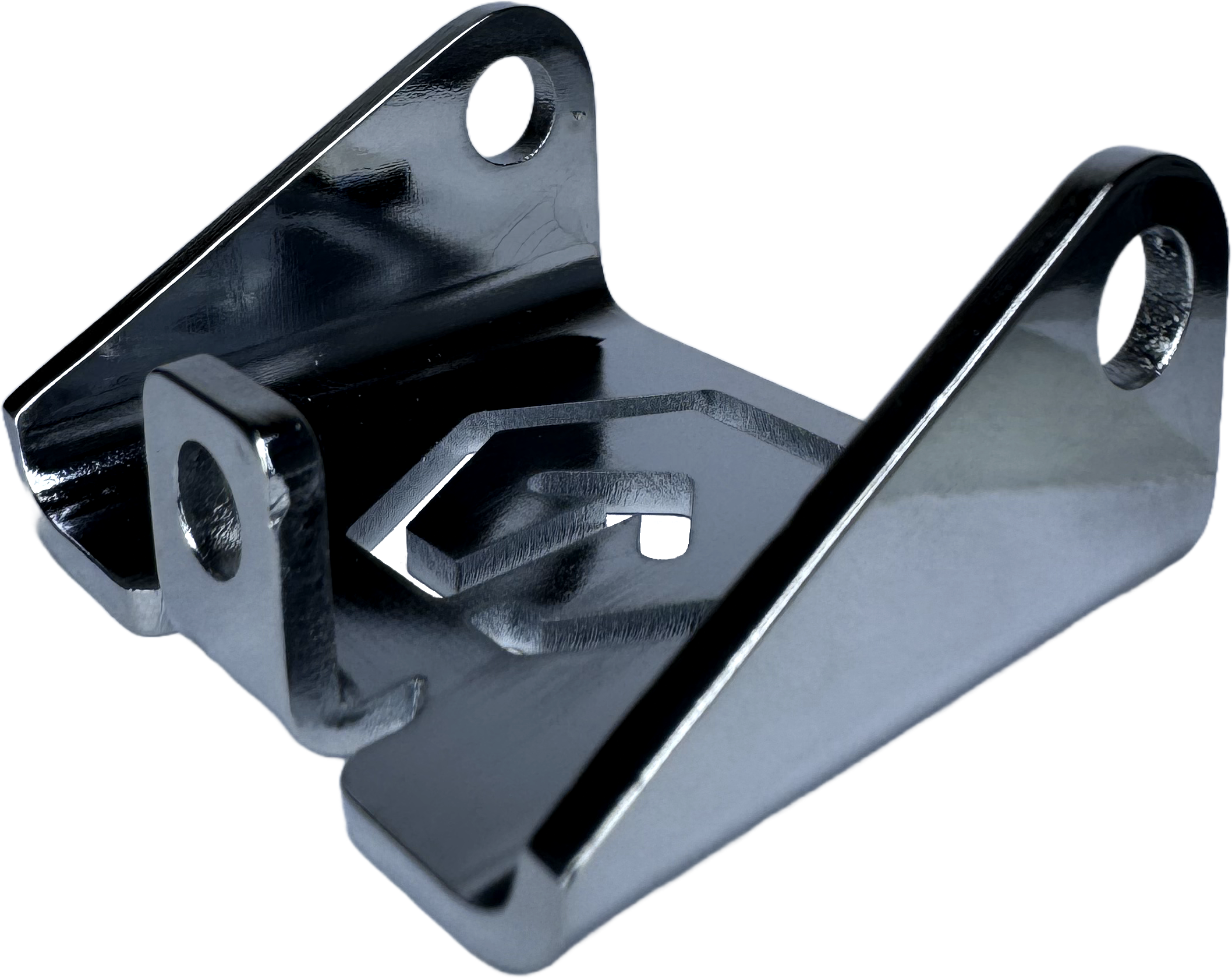

Geomiq takes on prototype and production sheet metal services and cutting. We can support one-offs, batch production, welding and assembly as well as stockholding in line with your requirements. As experienced sheet metal fabricators, we excel in custom sheet metal fabrication, providing high-quality sheet metal for fabrication needs. We have earned our reputation amongst the world's leading companies for high-quality and precision sheet metal services, working on the very latest of technologies.

Our Waterjet Cutting service is ideal for cutting Sheet Metal components between 18mm-40mm.

We offer high-precision fibre and CO2 Laser Cutting to produce the most accurate cuts and contours possible to flat metal sheets.

Whether you’re after magnetic or hydraulic bending of Sheet Metal components, we’ve got you covered.

Order Sheet Metal Fabricated parts of the highest quality – delivered to your door in days.

At Geomiq, we’re proud to partner with 260+ experienced and highly vetted sheet metal manufacturers, who have a proven track record of making high-precision Sheet Metal parts (cut, folded and finished) for customers all over the globe. Whether you need sheet metal services for prototyping or production runs, we ensure precision and quality in every step of the process. You can rest assured that with Geomiq, you’ll receive the perfect custom Sheet Metal parts – the first time, every time.

Order now to receive your custom sheet metal parts in as little as 5 days! Put in your instant quote for sheet metal now!

We offer functional or cosmetic sheet metal and finishing processes; from polishing and plating to powder coating and more.

With cutting areas of up to 6000 x 2000mm, and presses up to 80T, we’ll help you with the Sheet Metal Fabrication of both small components and larger Sheet Metal parts.

From enclosures and brackets to frames and chassis, we’re proud to create beautiful Sheet Metal parts for any and every industry.

We offer most gauges of steels, copper, aluminium and more, in various thicknesses as part of our wide range of materials for sheet metal.

We offer one-off prototypes, complex fabrications, assemblies, and up to 50,000 units at the most competitive prices. Our engineers provide project management and can support annual stockholding for long-term, cost-effective sheet metal fabrication

Upload your Sheet Metal CAD to our platform, select your lead time and get an instant or 24hr Sheet Metal online quote.

We assign the most suited sheet metal fabricators to your order, with the Sheet Metal production starting immediately.

We gaurantee your sheet metal part order arrives to specification, with our industry leading virtual and physical quality standards.

We ship your sheet metal parts on express services where possible, including physical delivery notes and inspection reports. You can also track your custom sheet metal fabrication parts every step of the way

Upload your Sheet Metal CAD to our platform, select your lead time and get an instant or 24hr Sheet Metal online quote.

We assign the most suited sheet metal fabricators to your order, with the Sheet Metal production starting immediately.

We gaurantee your sheet metal part order arrives to specification, with our industry leading virtual and physical quality standards.

We ship your sheet metal parts on express services where possible, including physical delivery notes and inspection reports. You can also track your custom sheet metal fabrication parts every step of the way

We employ highly skilled engineers to triple-check all of your files and parts from the initial sheet metal quote to final inspection – We guarantee precision and quality in our sheet metal fabrication services.

At Geomiq, we know your time is valuable – and we’re passionate about helping you save more of it. When you upload your files, we’ll get you a quote within one business day – and our our network of highly experienced sheet metal fabricators will ensure the finished products are of the highest quality possible.

We partner with 260+ highly vetted and experienced manufacturers from 50+ different countries, so that you can benefit from more options, greater capabilities and the highest standards in the world – all from a single access point custom sheet metal fabrication and processing

See all finishes

Filter By:

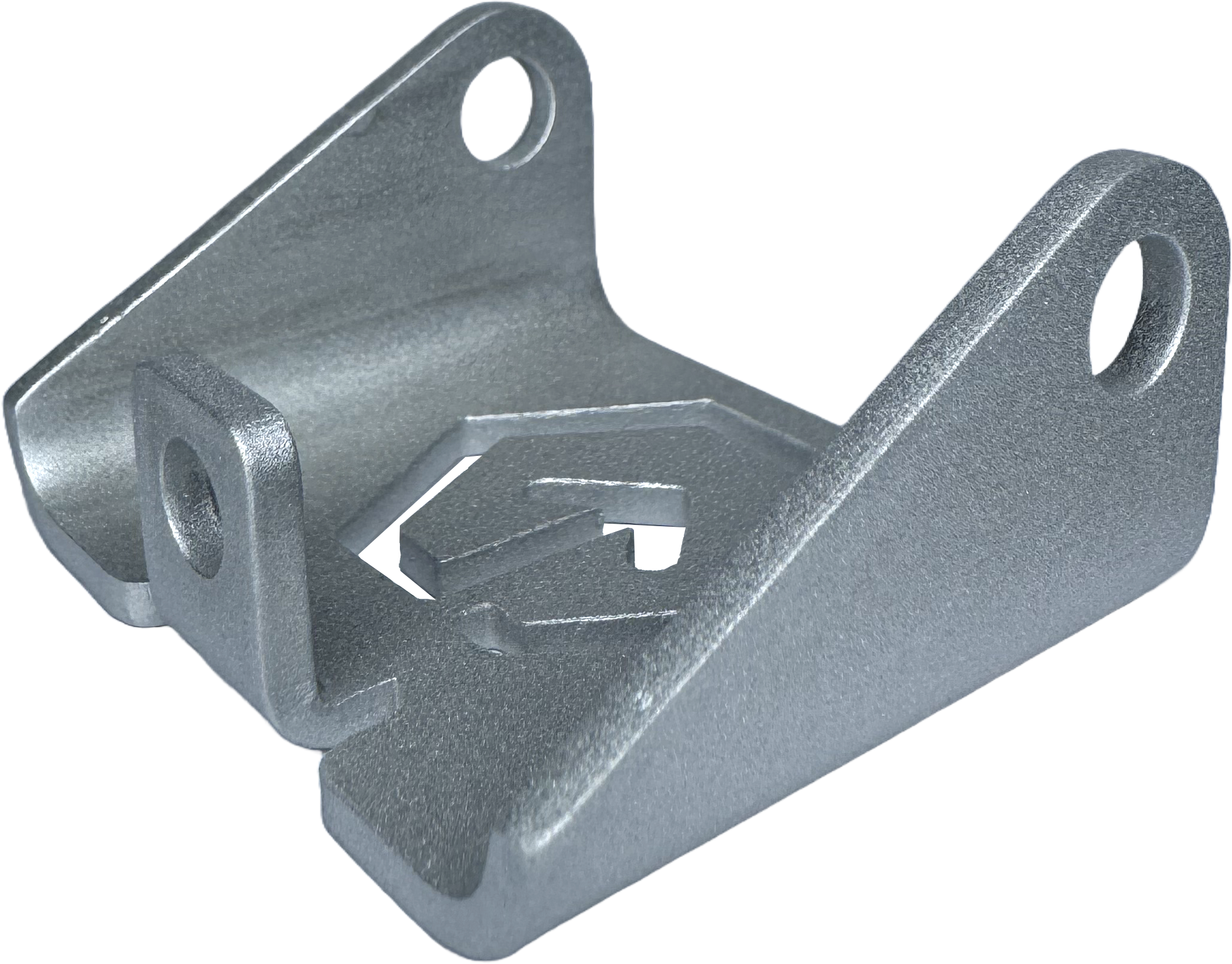

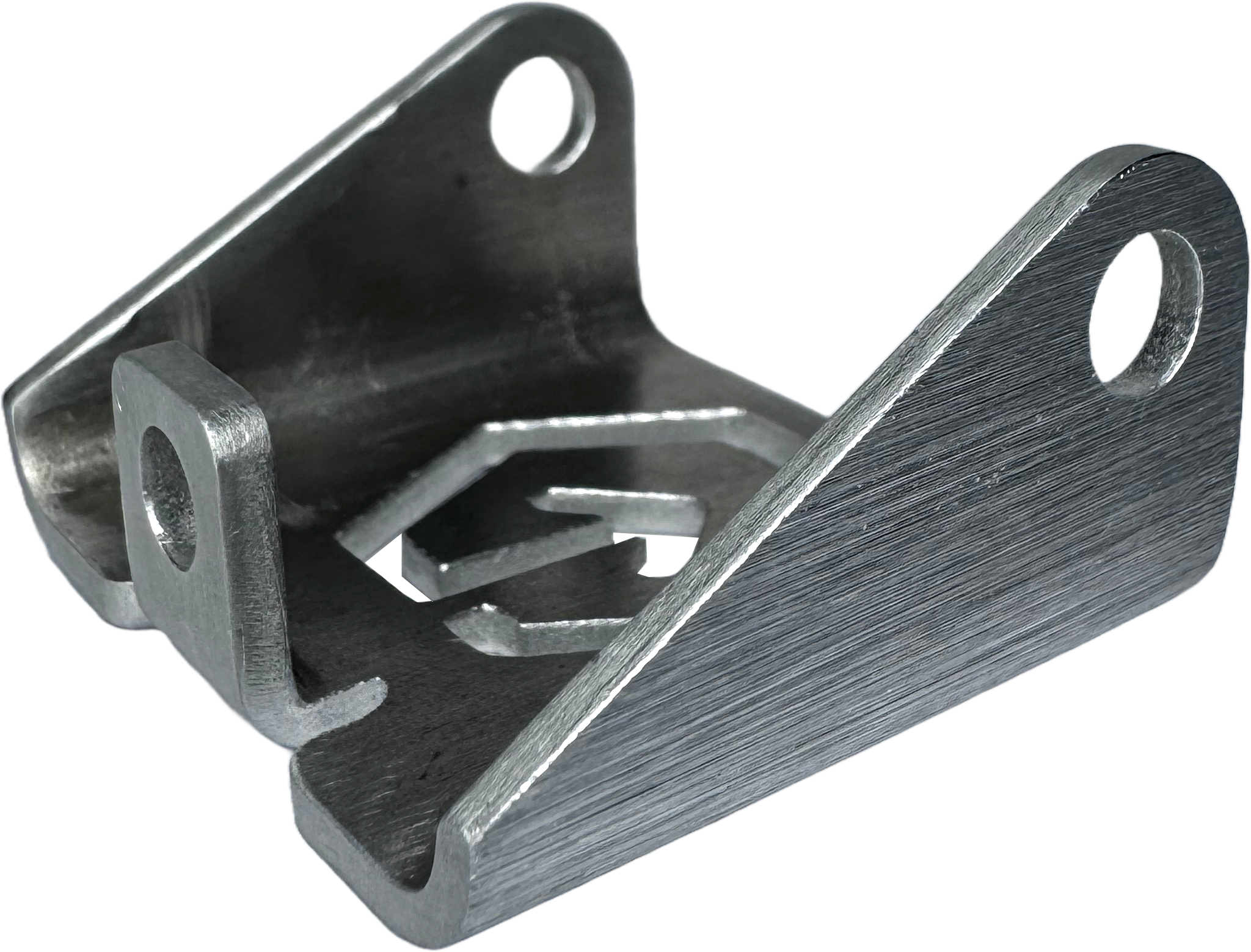

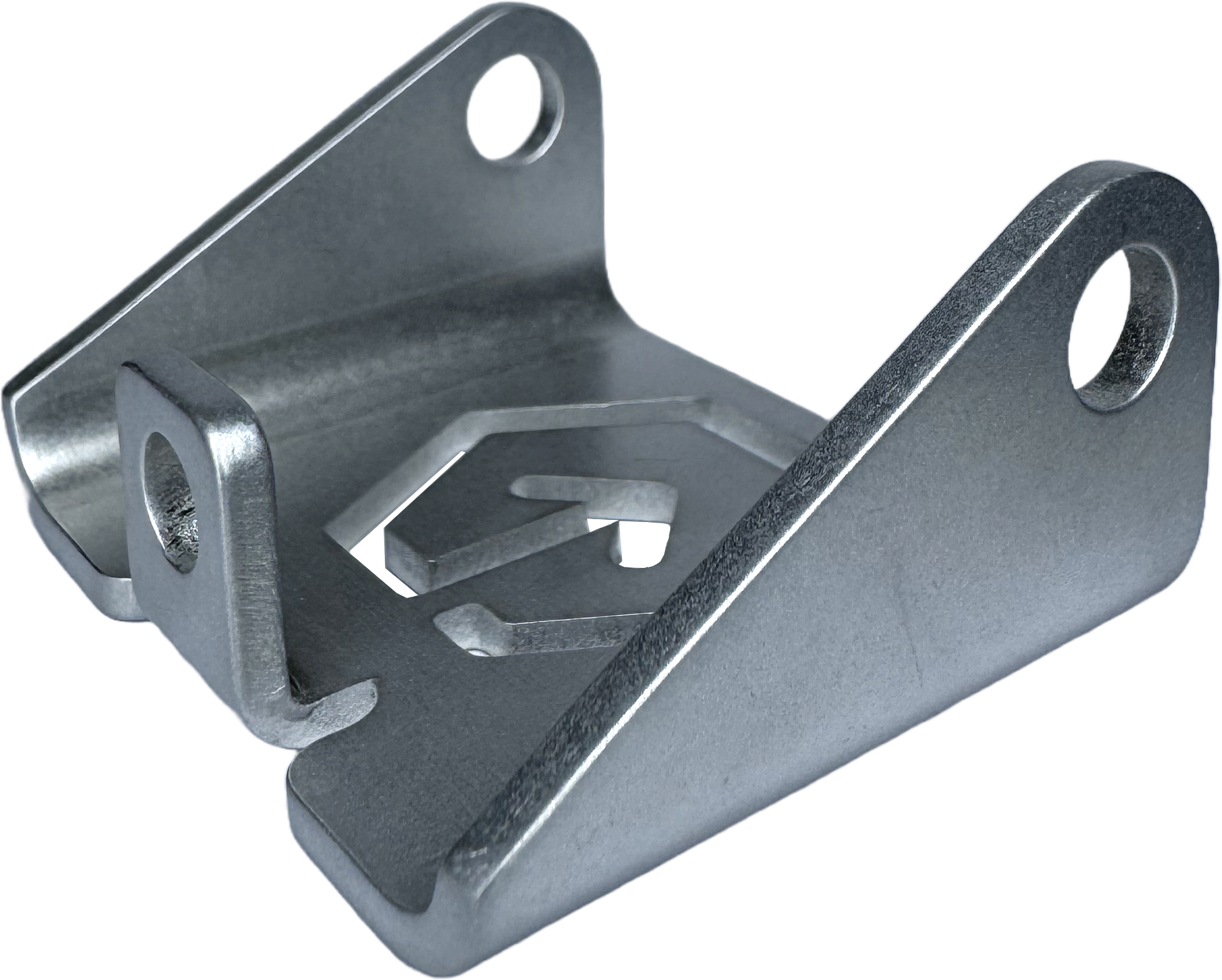

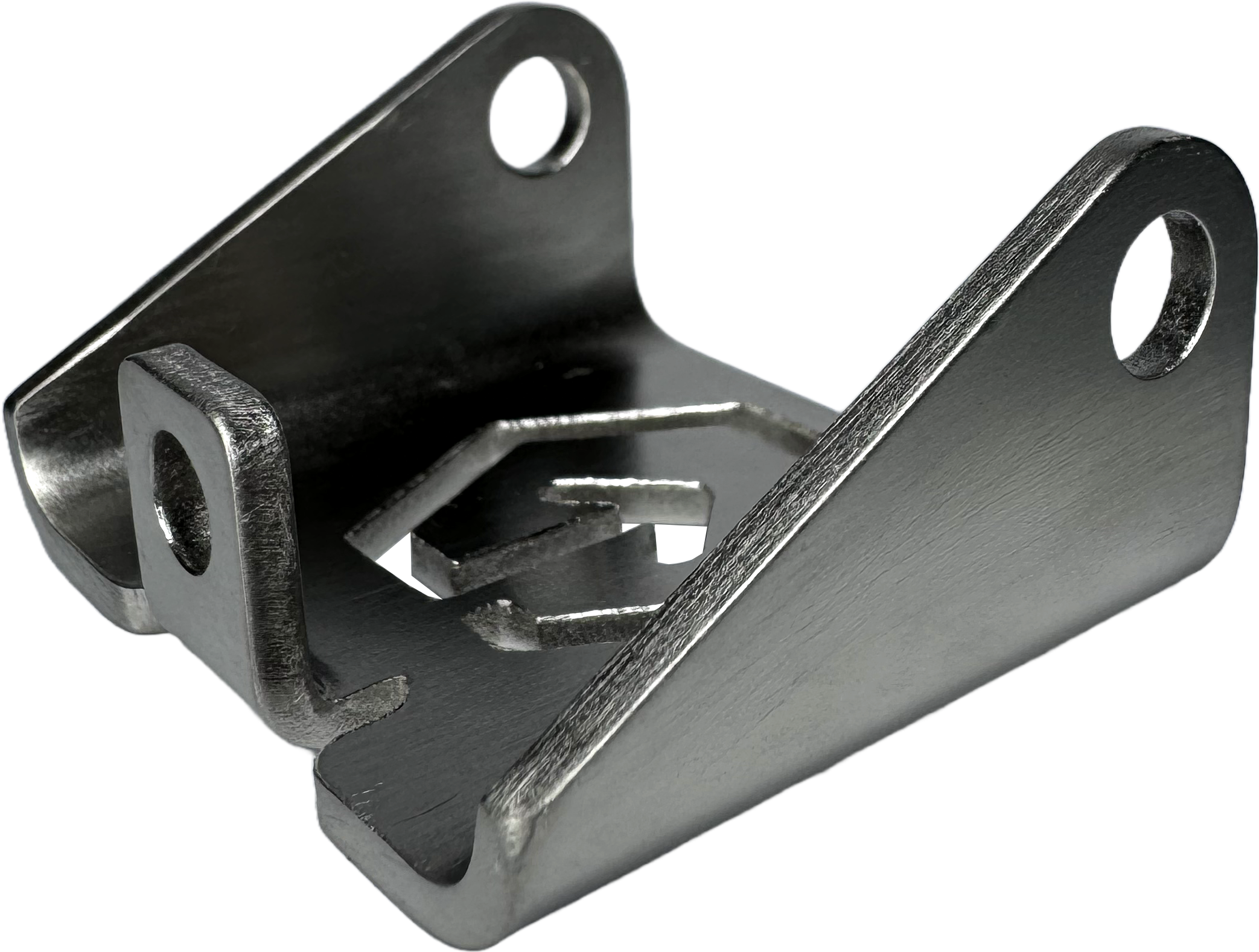

There are various sheet metal surface finishes that are available off the shelf, including brushed and treated variants.

Visible tooling marks and light surface scratches.

Visible tooling marks and light surface scratches, oil coated to prevent corrosion.

Smooth mill finished, cold rolled and moderately reflective.

Smooth mill finished, cold rolled and slightly more reflective than 2B finish.

Appears with a rough pattern, high level of corrosion resistance.

Brushed one side with 150-180 grit grain in one direction.

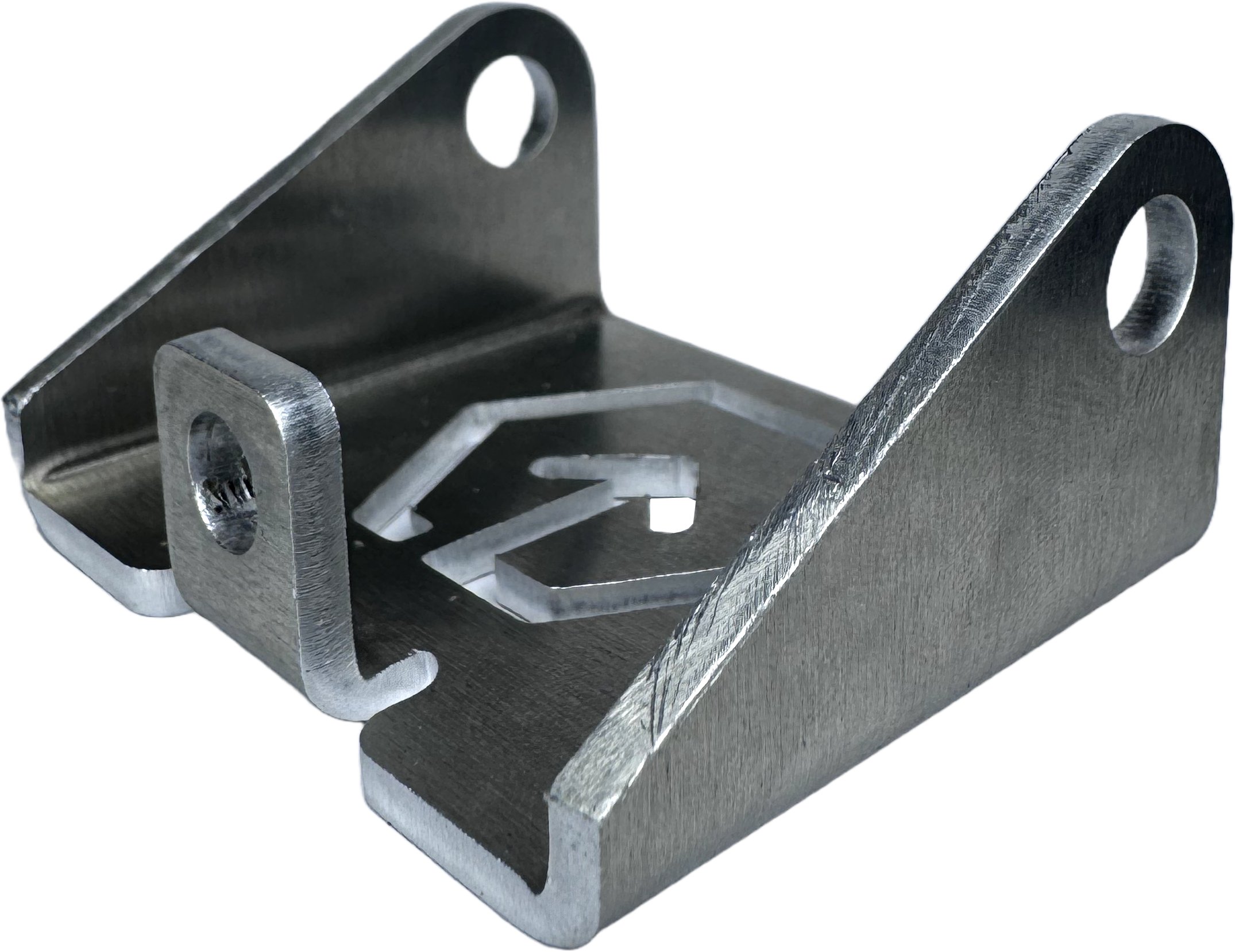

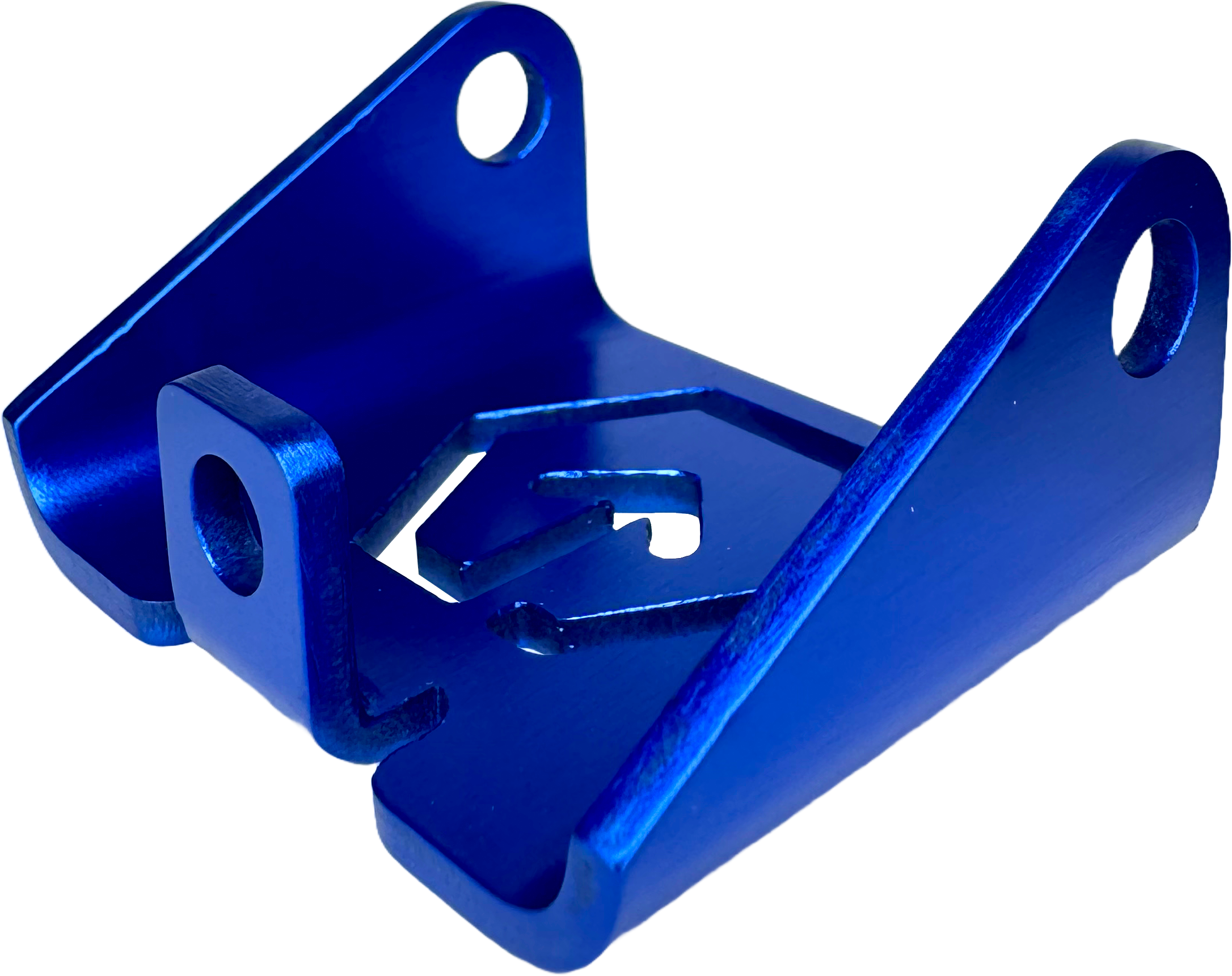

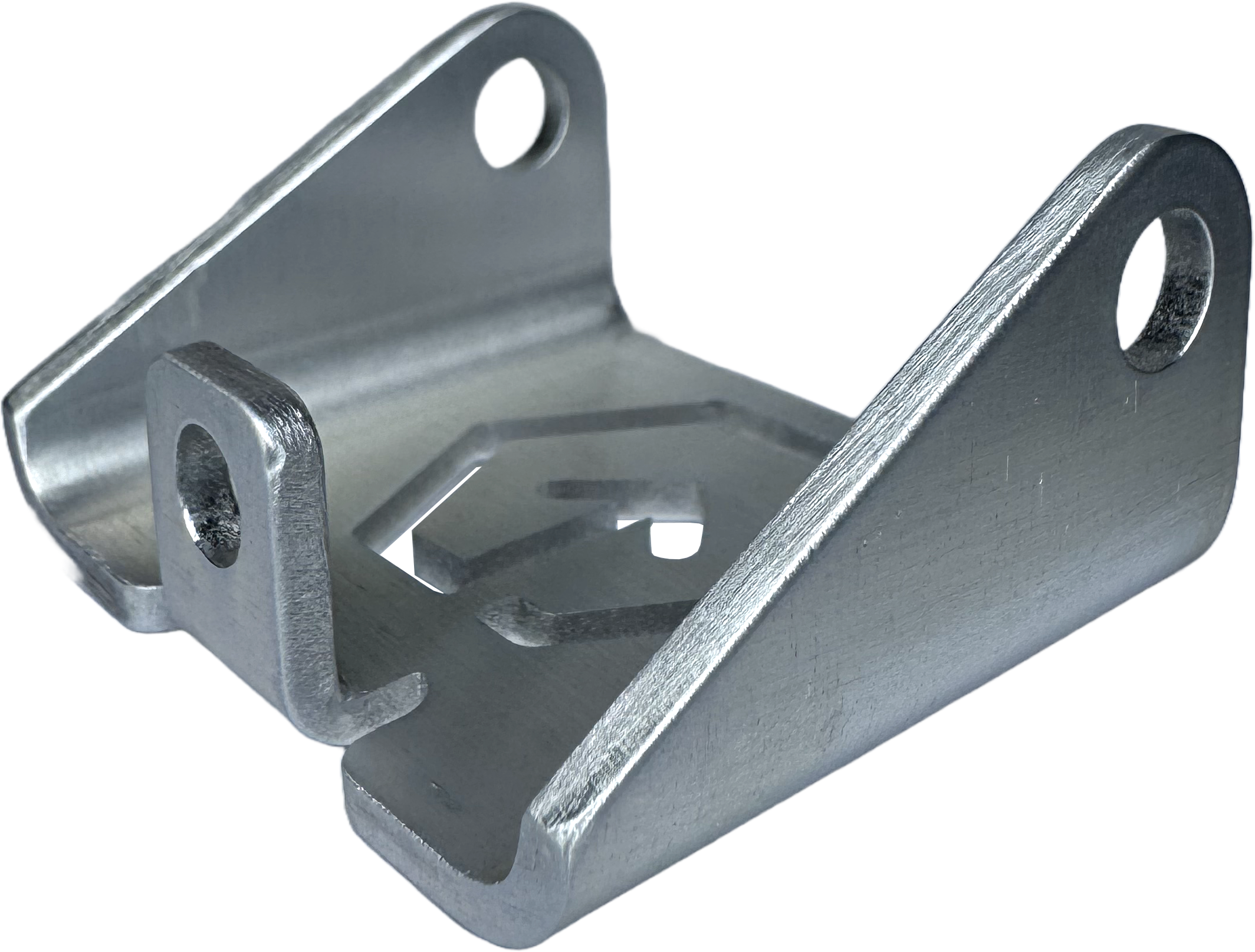

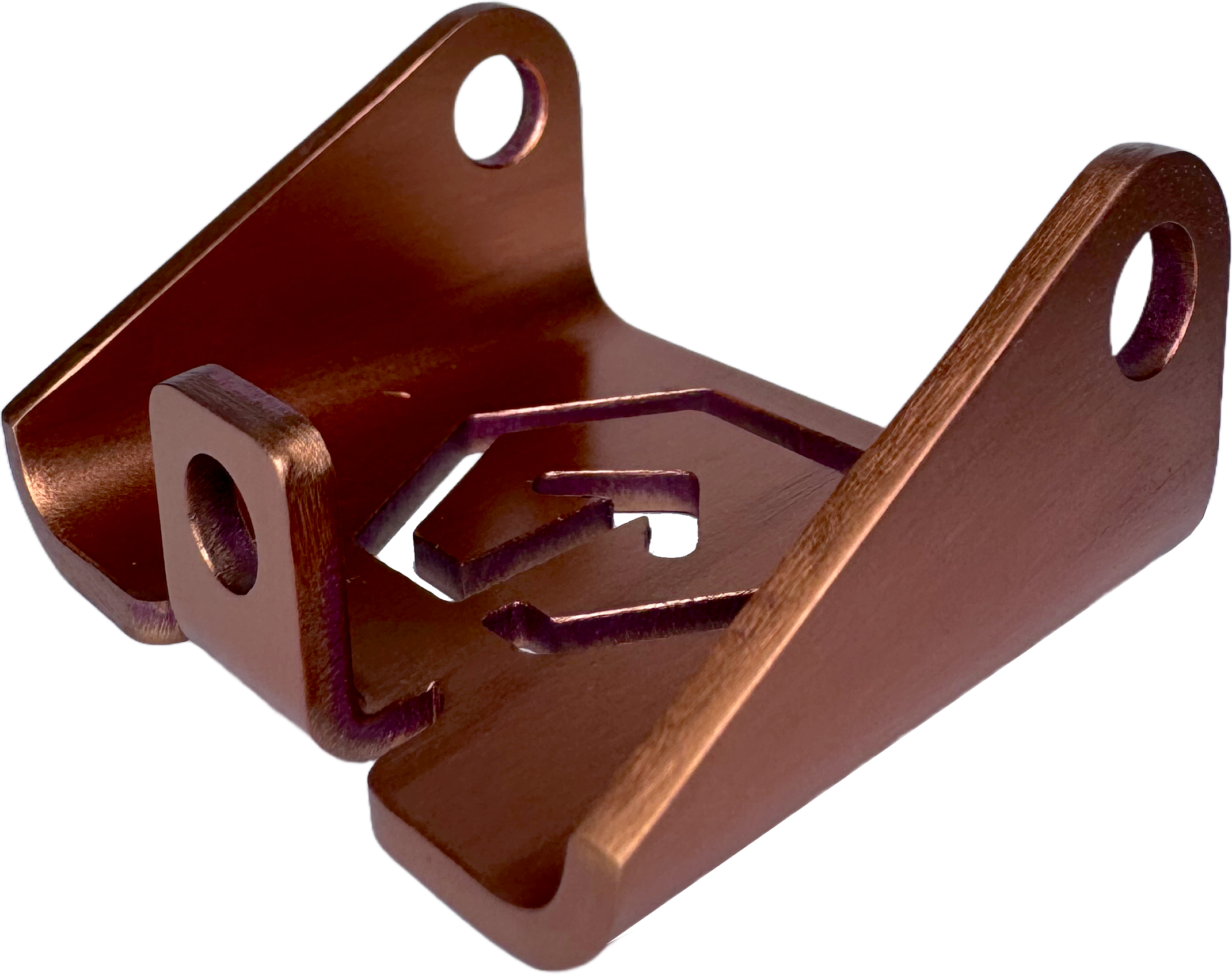

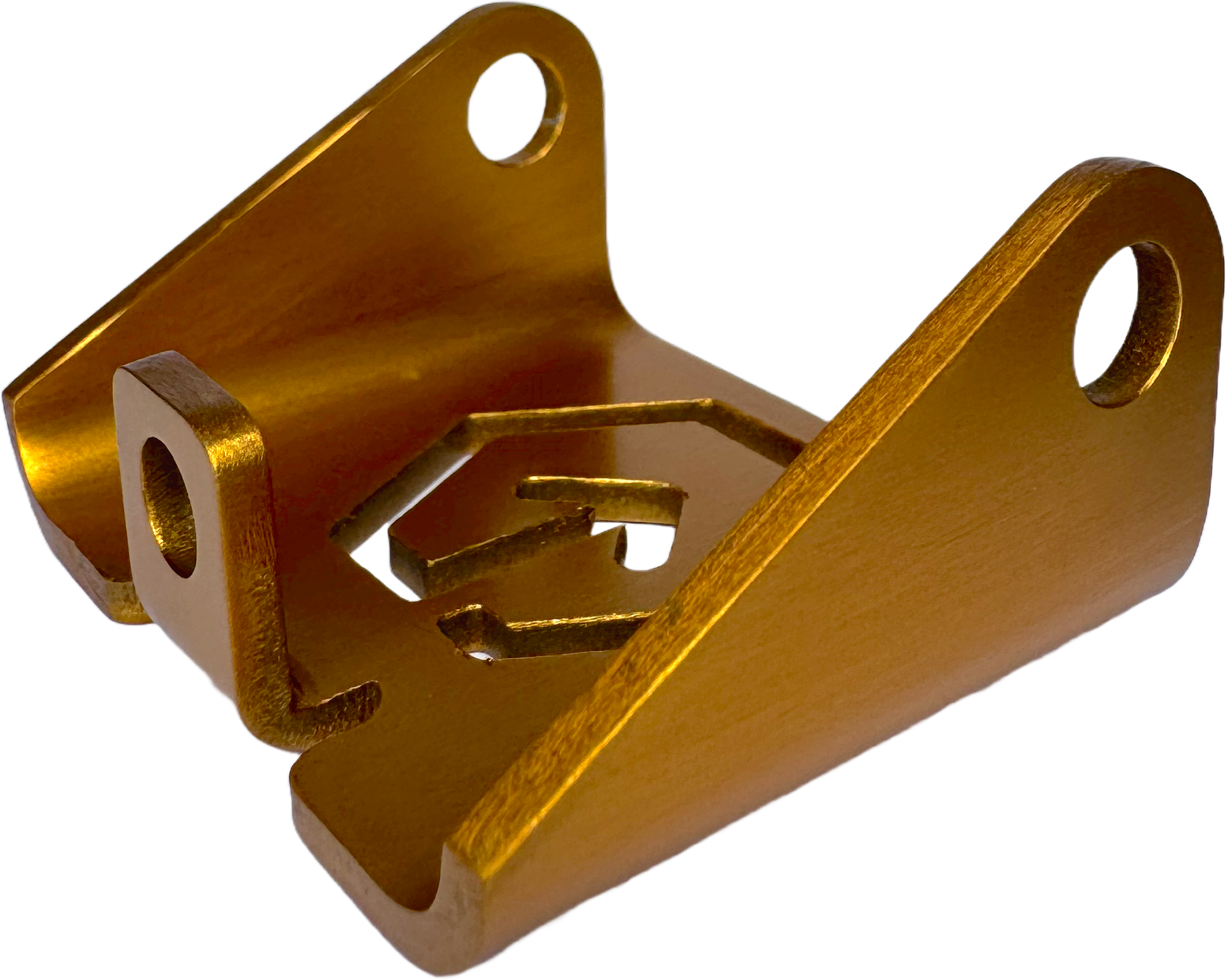

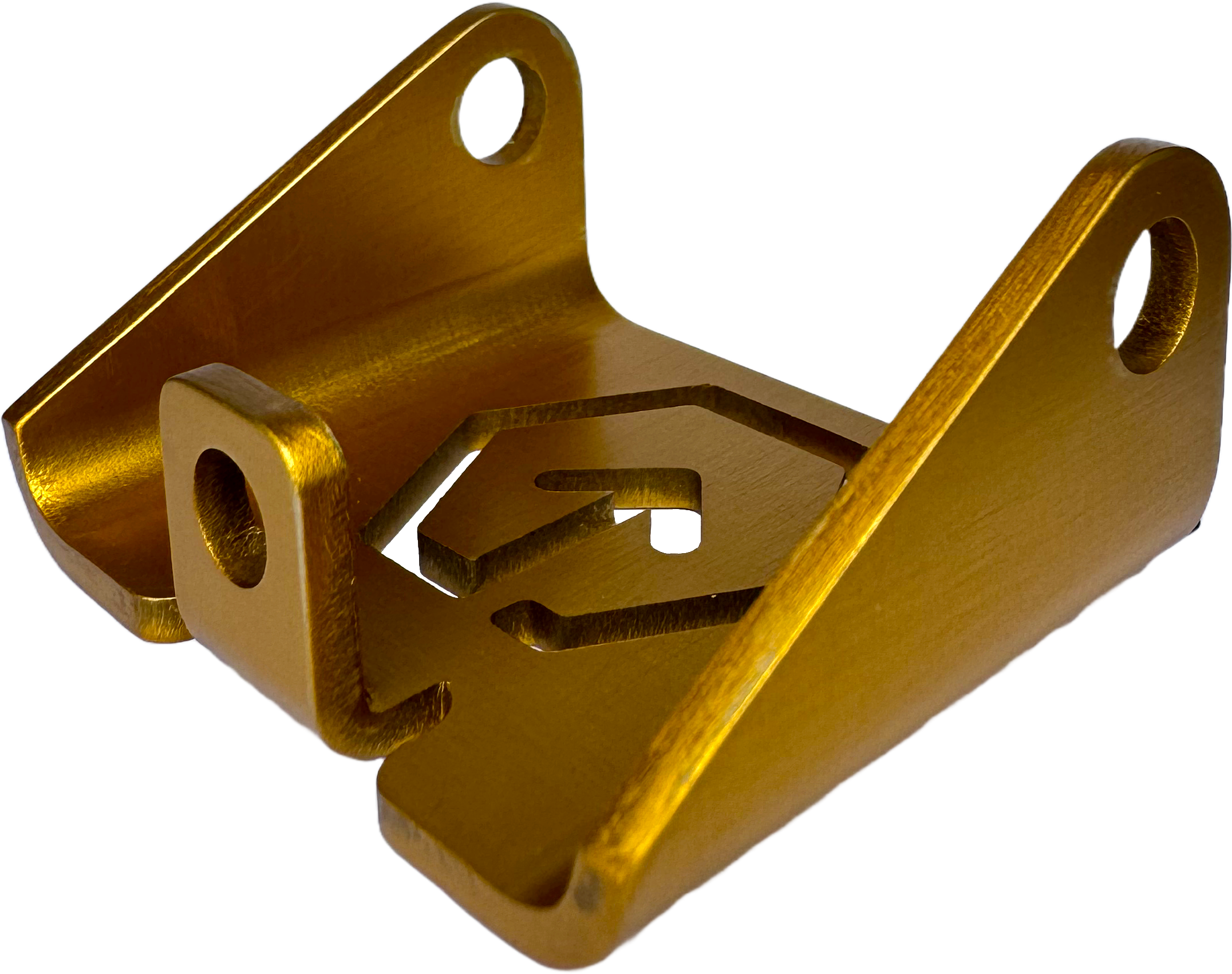

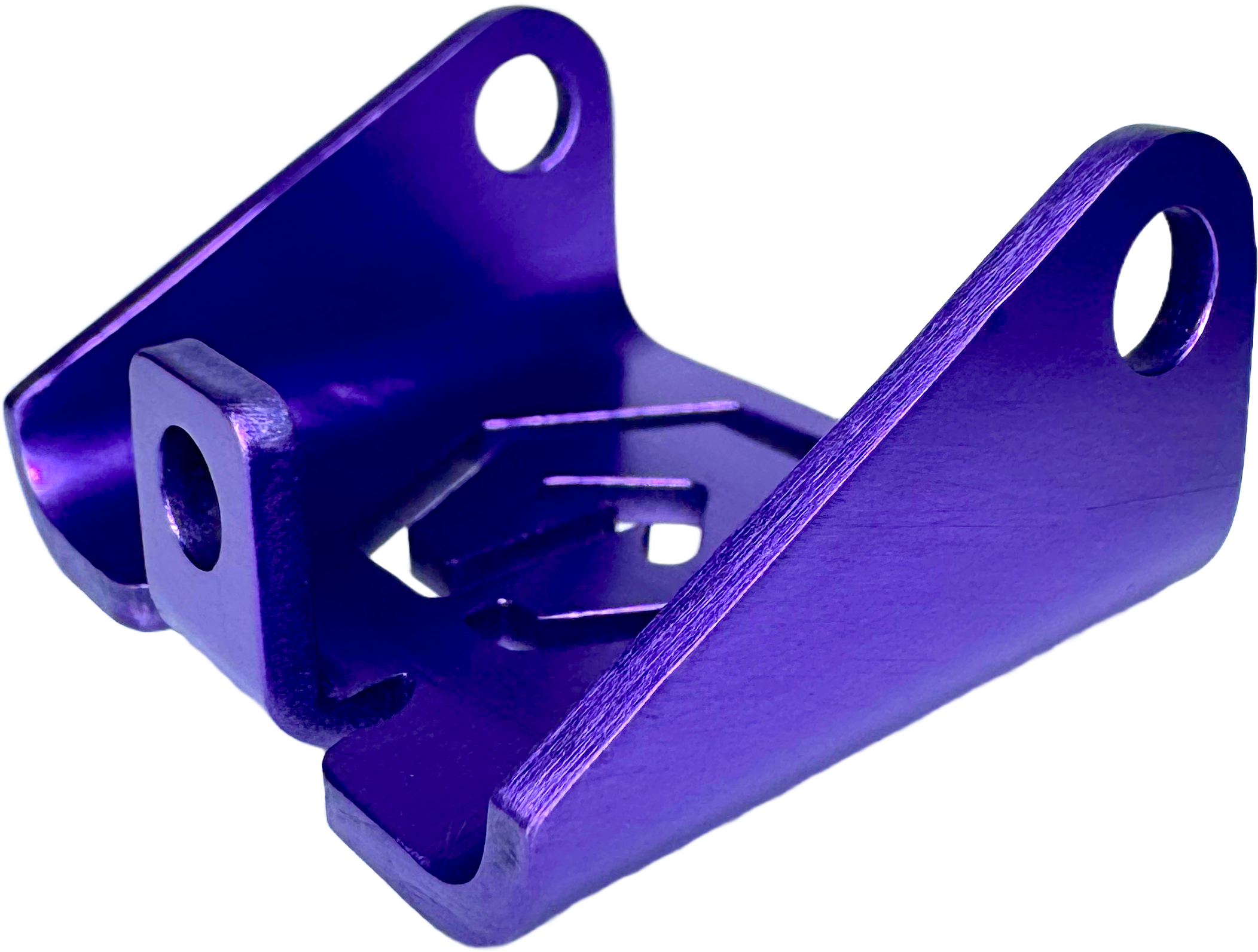

Type 2 sulphuric anodising is usually done to protect the surface or apply a coloured dye to improve aesthetic appeal. Anodised colours can be matched closely to specific Pantone or RAL colours when using our colour tolerance guide. Standard thickness ranges are typically between 5µm to 25µm.

Blue

Provides increased corrosion resistance and improves aesthetic appearance.

Clear

Provides increased corrosion resistance and improves aesthetic appearance.

Silver

Provides increased corrosion resistance and improves aesthetic appearance.

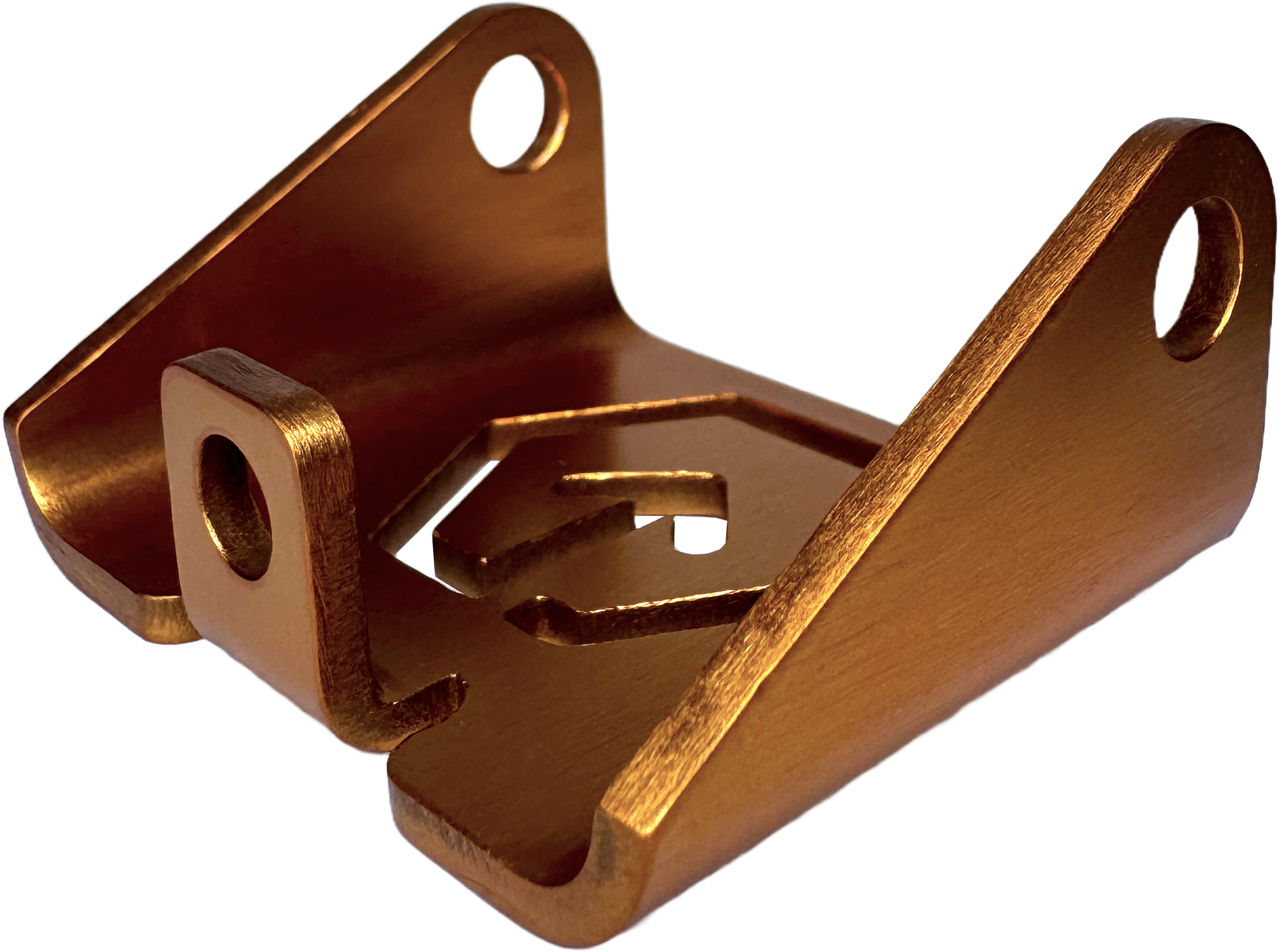

Bronze

Provides increased corrosion resistance and improves aesthetic appearance.

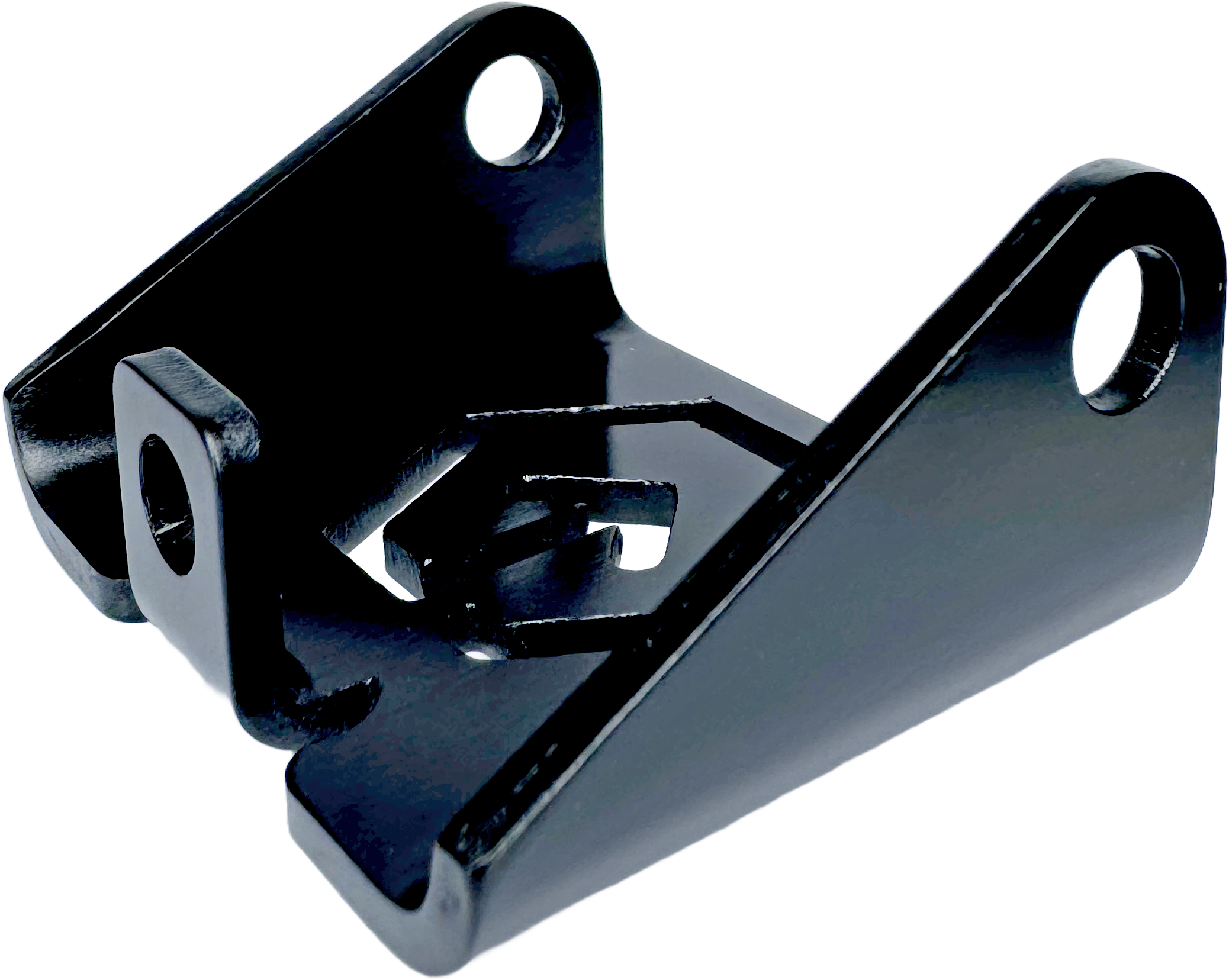

Black

Provides increased corrosion resistance and improves aesthetic appearance.

Gold

Provides increased corrosion resistance and improves aesthetic appearance.

Green

Provides increased corrosion resistance and improves aesthetic appearance.

Yellow

Provides increased corrosion resistance and improves aesthetic appearance.

Purple

Provides increased corrosion resistance and improves aesthetic appearance.

Orange

Provides increased corrosion resistance and improves aesthetic appearance.

More colours available including colour matching

Provides increased corrosion resistance and improves aesthetic appearance.

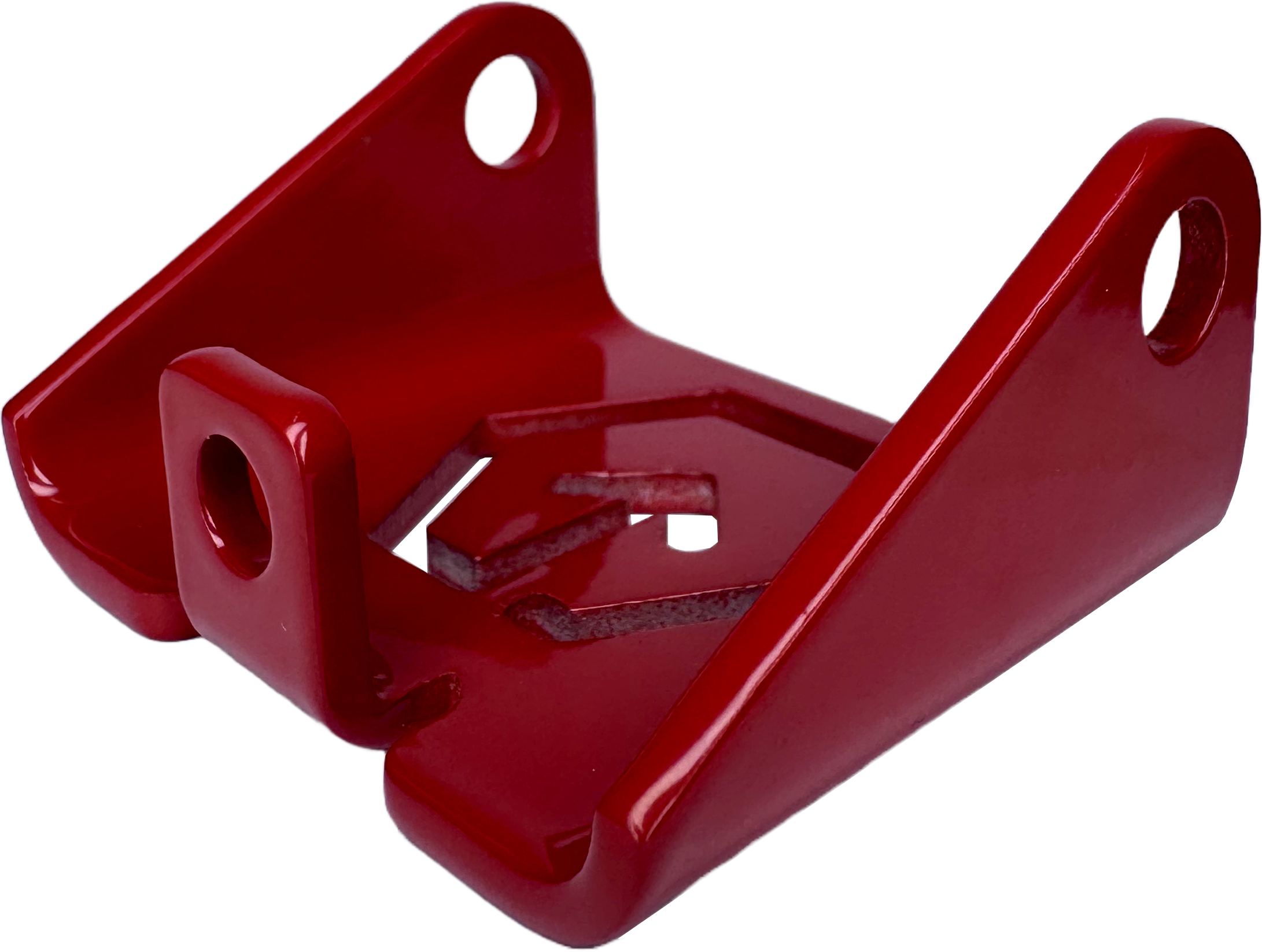

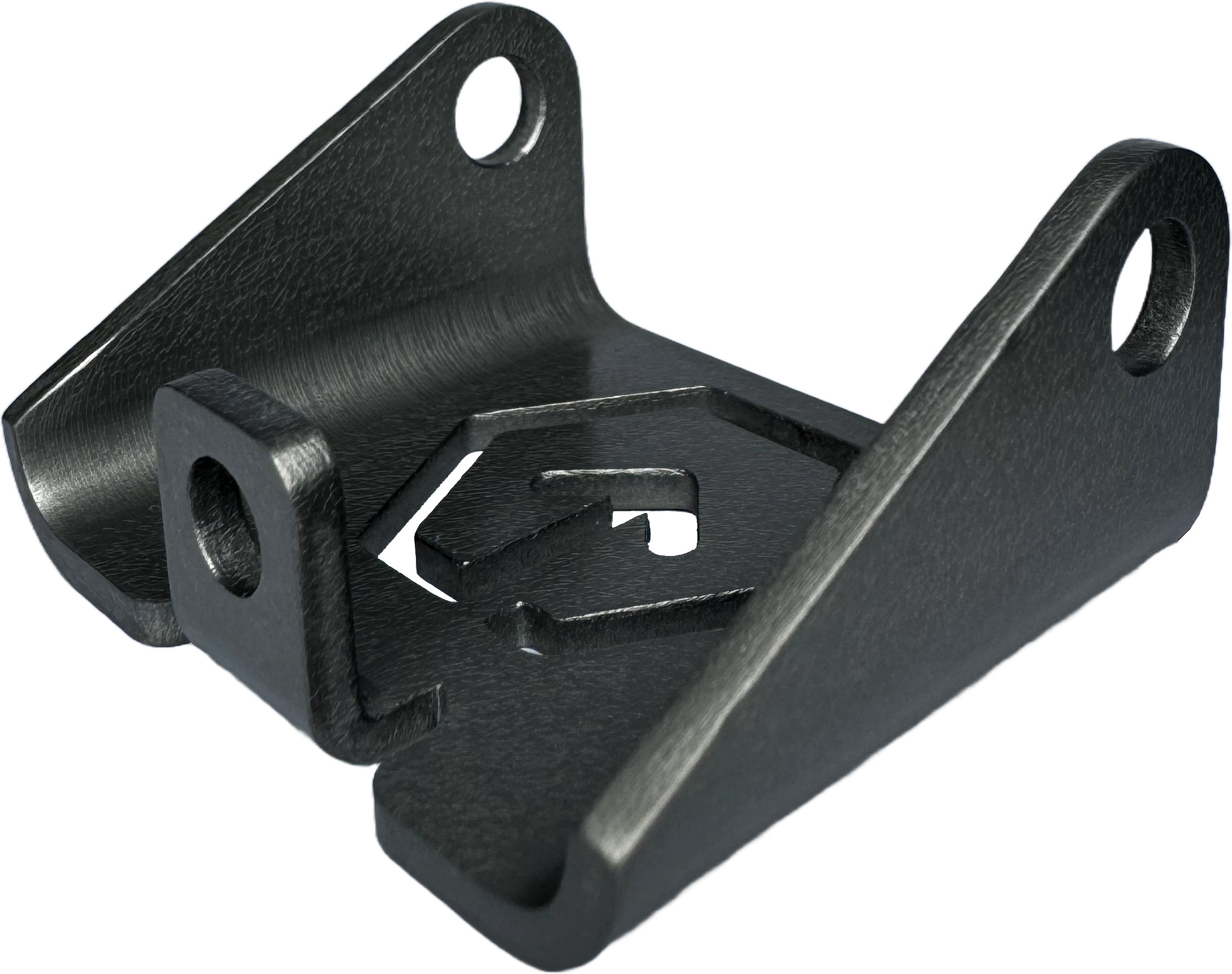

Powder coating is a common finish for sheet metal components due to the continuous and even coating that protects the base material from corrosion as well as improves the aesthetic appearance. All exact match Pantone and RAL colours are available with Powder Coating. Standard thickness ranges are typically between 50µm to 70µm.

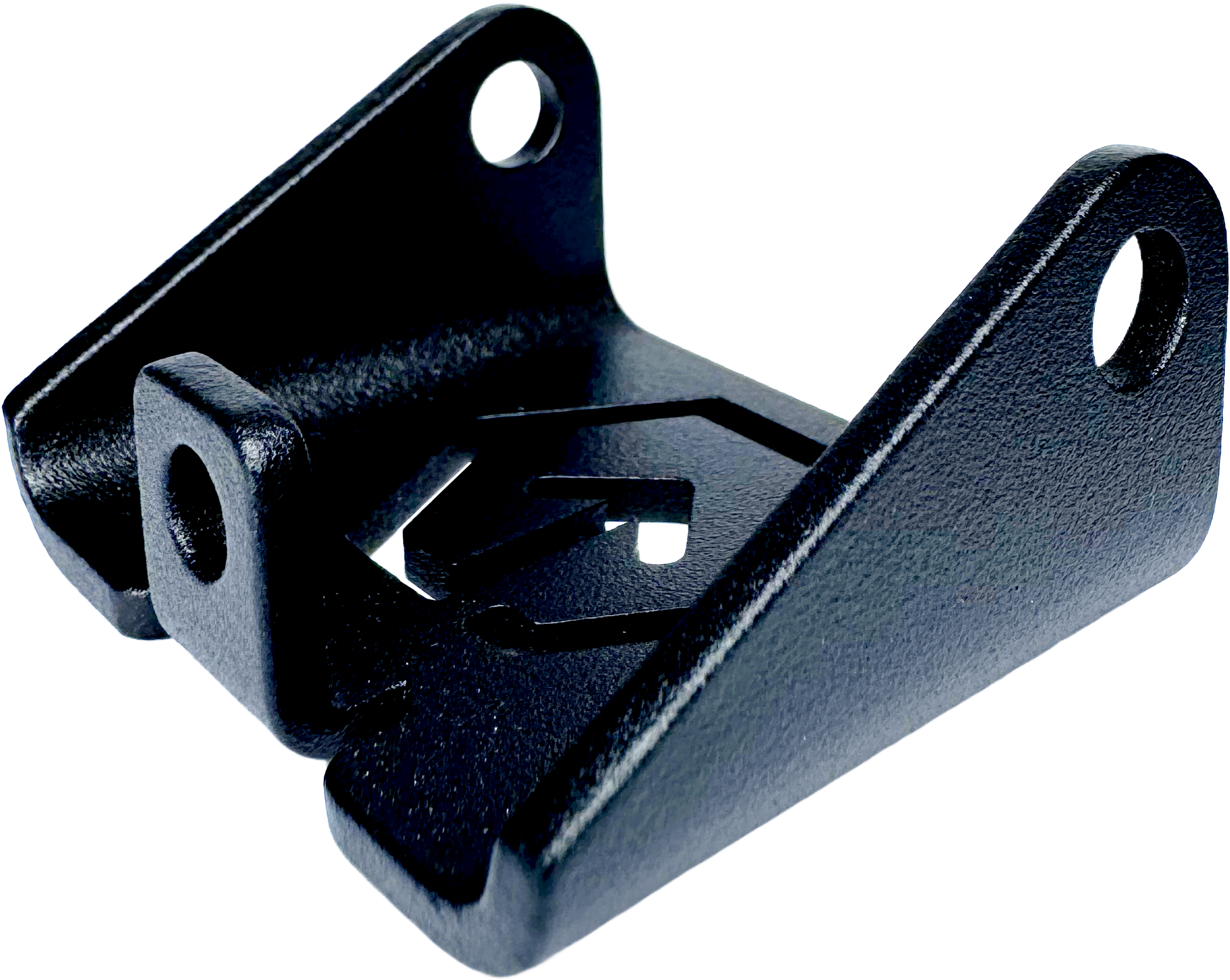

RAL 9005 Black (Matte 30%±5%))

A grainy matte appearance that does not reflect much light.

RAL 9005 Black (Satin (60%±5%))

A smooth surface with slightly reflective appearance.

RAL 9005 Black (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

RAL 9005 Black (High Gloss (80%±5%))

A smooth surface with very highly reflective appearance.

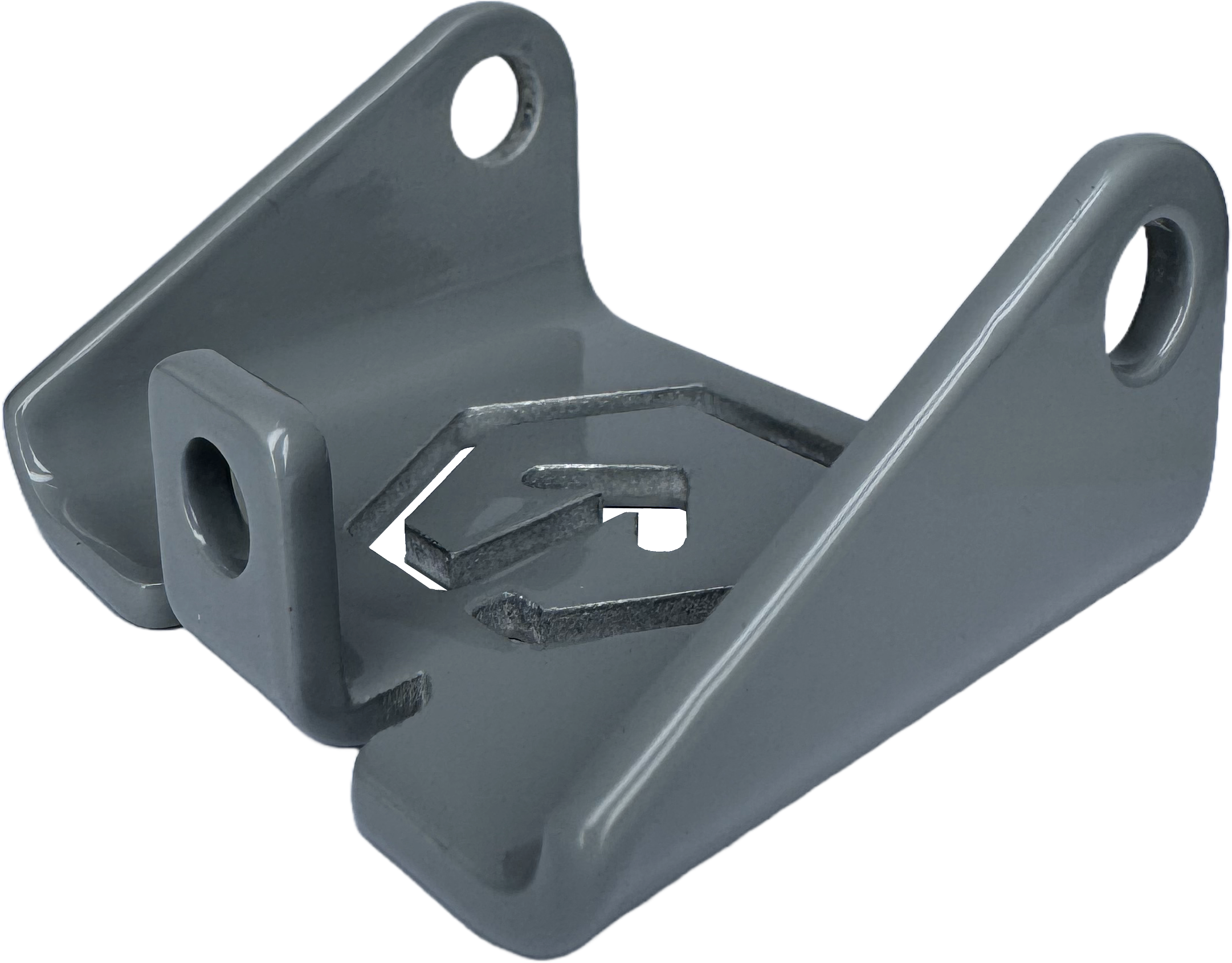

RAL 7004 Grey (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

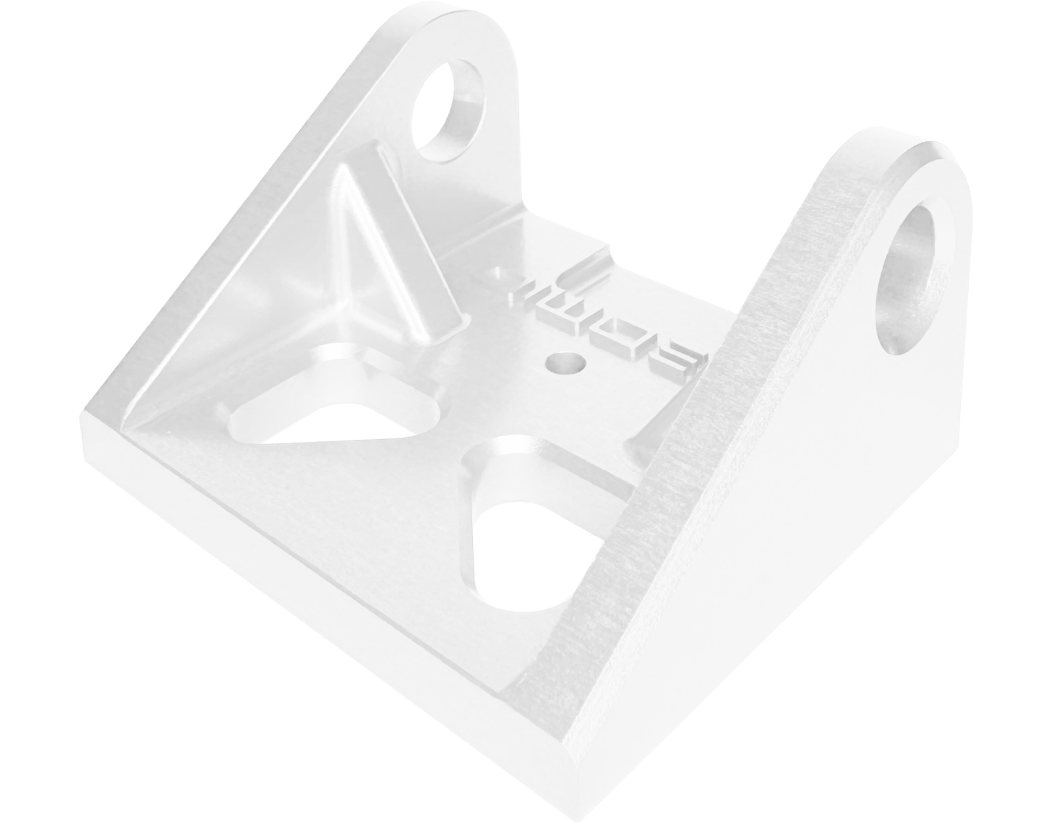

RAL 9010 White (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

RAL 3001 Red (Gloss (70%±5%))

A smooth surface with highly reflective appearance.

All RAL colours available including colour matching

A smooth surface with highly reflective appearance.

Mechanical finishes are typically for improving aesthetics or preparing a base material for an additional treatment.

Bead Blast

Grainy, slightly matte texture that removes tool marks and light scratches

Mirror Polishing

Hand polished to create high cosmetic mirror-like appearance.

Vibratory Polished

A great way to de-burr and smooth the surface of parts leaving feint grainy lines.

Brushed

A single directional heavy grain is mechanically applied to the material.

Tumbling

A great way to de-burr and lightly polish the surface of parts.

Chemical finishes are used to treat components in bulk, as they are relatively cost effective and cover all surfaces of a component.

Electropolishing

Shiny and smooth surface that also enhances corrosion resistance.

Satin Finish

Grainy, slightly matte texture that removes very light marks and scratches.

Chemically brightened

A reflective and shiny surface that is often used to prepare parts before anodising.

Iridite NCP

Excellent corrosion resistance, adhesion promotion and non-toxic.

Passivating

Excellent corrosion resistance by removing impurities to increase durability.

Chemical Blackening (Black Oxide Coating)

Applies a thin and uniform black finish that prevents corrosion and wear.

Hard anodising is a thicker variant to sulphuric anodising, with the typical thickness between 25 to 60µm thick although it is possible to go thicker than this. Will conform to MIL-A-8625, Type III, Class 1/2.

Black brightened

A slightly crackled smooth surface texture.

Clear Natural

A slightly crackled smooth surface texture with grey appearance.

Matte Black

A slightly crackled grainy and pitted surface texture.

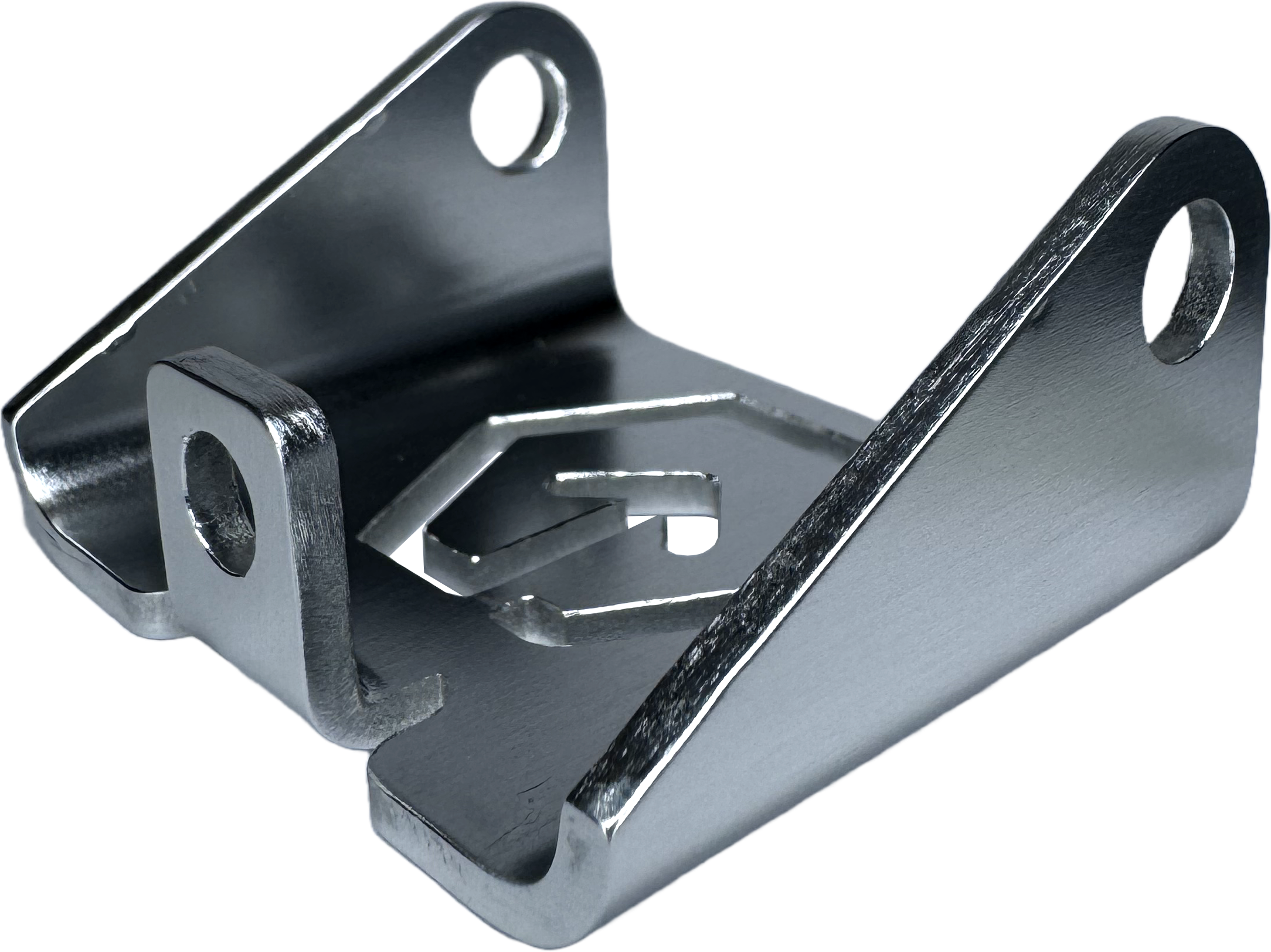

Metal plating provides a uniform thickness coating, which offers protection from corrosion, oxidation and wear. Parts will appear brighter than in photos and are reflective. Plating thickness ranges are typically between 10µm to 25µm depending on the type of plating.

Electroless Nickel Plating

Excellent for corrosion resistance, very cost effective. Has slight reflective surface.

Chrome Plating

Highly reflective and evenly applied surface finish, similar to mirror polish.

All uploads are secure and confidential.

We have hundreds of global manufacturing partners that ensures we are highly competitive and have unlimited capacity. We can route jobs geographically to reduce lead times and shipping costs as well as reducing the carbon footprint of each order of custom sheet metal parts. All of our sheet metal services partners have stringent onboarding and we use data to track on-time deliveries, quality and pricing. This ensures your job is always with the best suited manufacturing partners for sheet metal fabrication.

Sheet metal fabrication is the process of transforming flat metal sheets into various shapes and structures through cutting, bending, and assembling techniques. It involves the creation of precise sheet metal parts using specialized machinery and tools. Learn more in our comprehensive sheet metal fabrication guide.

See our case studies in action. Discover how we turn ideas into products with our prototyping and manufacturing capabilities.

Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Jamie Fairclough

Design Lead

Industrial Robotics | Arrival

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

James Batstone

Future Product Research Lead

Brompton Bikes

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

Alex Leck

Design Engineer

JCL Lighting

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

All uploads are secure and confidential.