CNC Machining vs Sheet Metal Fabrication

Sheet metal fabrication and CNC machining are among the most popular manufacturing processes. Due to their many beneficial characteristics, various industries apply these processes to produce a vast range of parts and products. However, machining and fabrication are different processes involving varying operations and techniques that make them better suited to different applications. This article compares machining vs fabrication, exploring their processes, applications, and differences, helping you select the best manufacturing process for your project.

What is CNC machining?

What is sheet metal fabrication?

Machining vs fabrication: direct comparison

Machining vs fabrication: selecting the right process for your application

Conclusion

What is CNC machining?

CNC machining is a subtractive manufacturing process that creates parts by selectively cutting away pieces of a block of material until a part forms. In this process, a computer-controlled cutting tool progressively carves out a pre-programmed geometry from a solid material block in a process akin to sculpting. The computer accurately controls the cutting tool and workpiece's speed, movement, and orientation, continuously adjusting these parameters until the desired geometry forms.

CNC machining

CNC machining comprises various independent operations that utilise CNC to create parts. These operations vary by machine type, material removal technique, and geometry produced. The most common CNC machining operations are CNC milling and CNC turning.

CNC milling: In CNC milling, a motor-driven spindle feeds a rotating cutting tool into a stationary workpiece, selectively removing material. The machine continually repositions the workpiece and cutting tool to enable the tool to access different sections of the workpiece. CNC milling typically produces cubic and parametric geometries. It can also create curves, contours, and holes.

CNC Milling

CNC turning: In CNC turning, the machine feeds a stationary cutting tool into a rotating workpiece. In this process, the workpiece, a block of material, is secured in place by a chuck attached to a spindle. During turning, the spindle rotates the workpiece, and the non-rotating cutting simultaneously moves into it, selectively cutting away pieces of material. CNC turning produces circular, cylindrical, helical, and conical geometries. Lathe machines perform milling.

CNC turning

Other CNC machining operations include CNC cutting, CNC routing, and CNC drilling. See our comprehensive CNC machining guide to learn about these processes and more about CNC machining. CNC machining is compatible with various materials, including metals, plastics, wood, glass, ceramics, stone, and many others.

CNC machining can produce a range of parts, shapes, features, and highly complex geometries. It is widely employed for rapid prototyping, custom one-off productions, and batch manufacturing. This technology is used in transportation, medical, machinery, aerospace, DIY, and many other industries to produce engine components, machine parts, custom prosthetics, gadgets, personalised items, and various consumer goods.

CNC machined components

Benefits

- Highly accurate and precise

- Can produce a wide range of complex and intricate geometries

- Produces single parts fast

- Suitable for both one-off and batch productions

- Compatible with a wide range of materials

Limitations

- CNC machines typically produce one part at a time, making it relatively slow for batch production

- The machining process generates a significant amount of scrap

- Machining cost significantly increases with part complexity

What is sheet metal fabrication?

Sheet metal fabrication is a manufacturing process comprising a series of operations that create parts, structures, and assemblies out of metal sheets. Fabrication typically begins with a sheet of metal. The workpiece is subjected to various operations, depending on the final finished product. The major fabrication operations are cutting, forming, and joining. The finished product may require one or more operations, depending on the application.

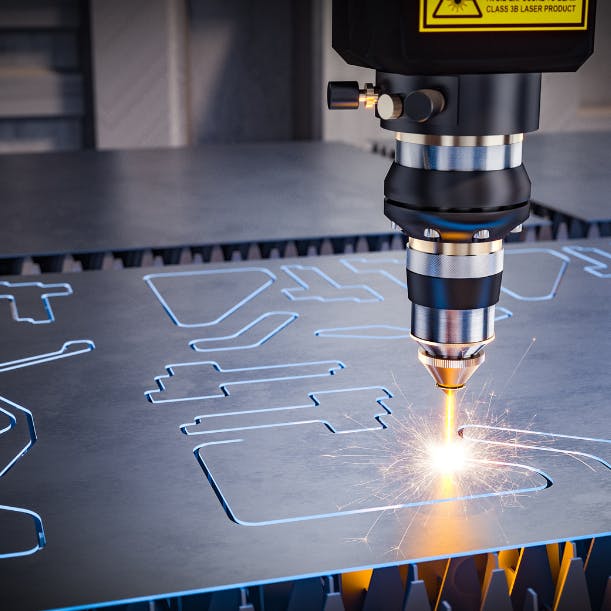

Cutting: Cutting involves slicing away portions of the workpiece to achieve a shape or size or to create a pattern. Cutting may be done with waterjets, lasers, plasma, torches, and mechanical cutters.

Laser cutting

Forming: Forming is the process of altering the shape and geometry of the workpiece without material removal via the controlled application of force. Forming operations include bending, drawing, stamping, spinning, and rolling.

Sheet metal bending

Joining: As the name implies, joining involves assembling separate fabricated pieces to form a single unit. Joining operations include welding, brazing, fasteners, and adhesive bonding.

Sheet metal welding

Sheet metal fabrication is used in transportation, maritime, electronics, construction, packaging, and many other industries to produce countless parts and structures, such as containers, chassis, enclosures, frames, brackets and mounts, barricades, vents, casings, fixtures, components, and panels. See our sheet metal fabrication guide for more information on this process.

Fabricated parts

Benefits

- Can produce very large parts and structures

- Produces high-quality, durable structures

- Highly scalable process. Sheet metal operations used for one-off productions can also be incorporated into production lines.

- Different options exist for every stage of processing

Limitations

- Predominantly compatible with metals

- Involves manual processes, which increase susceptibility to errors

- Operations can impact material properties

Machining vs fabrication: direct comparison

CNC machining and fabrication have different characteristics, making each better suited to different applications. The table below directly compares machining vs fabrication, pitting corresponding characteristics.

Machining vs fabrication comparison table

Machining vs fabrication: selecting the right process for your application

Geometry: Geometry is the primary consideration when comparing machining vs fabrication. In most applications, the desired geometry of the finished product solely dictates the manufacturing method. CNC machining can produce intricate, complex geometries. It can also create solid cubic, cylindrical, and parametric shapes out of 3D blocks of material. Fabrication, on the other hand, produces flat and hollow shapes with relatively simple geometries.

Size: CNC machining is limited in the largeness of parts and structures it can create. This limitation stems from the build size of CNC machines, with the maximum build size being around 3000 x 2000 x 800 mm.

Conversely, fabrication can produce extensive parts and structures using joining techniques. Some examples are cargo containers and spacecraft. On the other end of the scale, micromachining, an aspect of CNC machining, can produce features as small as 1 micrometre. These sizes are unobtainable via fabrication techniques.

Material: CNC machining is compatible with numerous materials, including metals, plastics, wood, glass, and ceramics. In contrast, fabrication is typically applied to metals. Note that joining and assembly in both manufacturing processes can involve multiple materials.

Cost: When comparing machining vs fabrication, different aspects of cost must be considered. However, as these manufacturing processes differ significantly, a direct cost comparison may not always be practical. Machining involves significant setup costs, as the most advanced industrial CNC machines can cost hundreds of thousands of pounds. Conversely, smaller hobbyist units cost hundreds to a few thousand pounds. In addition, machining time and cost vary with the geometry.

Similarly, fabrication set-up costs vary by the machines procured. The cost per unit also varies by the procedures involved. The same part fabricated by shearing, bending, fastening, and painting would cost more than when it's fabricated via laser cutting, bending, welding, and powder coating.

Production volume: CNC machining is excellent for prototyping and custom one-off production. It can also be used in batch manufacturing. However, this would require using multiple machines, as most CNC machines can only produce one part at a time. In addition, manufacturing time increases exponentially with part complexity. Conversely, most sheet metal fabrication processes can be incorporated into an automated production line, making it excellent for batch production. An example is a car assembly line with automated cutting, stamping, and joining operations.

Conclusion

Geomiq offers a range of CNC machining and sheet metal fabrication processes. To get started, simply head over to our instant quoting platform and upload your design. With a few clicks, you can receive your finished part in as little as three days. Not sure which process is best for your part? Our team of expert designers and engineers is available to guide you on design, process selection, and custom solutions to ensure seamless, cost-effective manufacturing for your project.

About the author

Sam Al-Mukhtar

Mechanical Engineer, Founder and CEO of Geomiq

Mechanical Engineer, Founder and CEO of Geomiq, an online manufacturing platform for CNC Machining, 3D Printing, Injection Moulding and Sheet Metal fabrication. Our mission is to automate custom manufacturing, to deliver industry-leading service levels that enable engineers to innovate faster.