Understanding Chemical and Mechanical Properties for Material Selection

In the world of material science, making the right choice of materials is crucial for the success of any engineering project. Whether you are designing an aerospace component, manufacturing automotive parts, or developing medical devices, understanding the key properties of materials is essential. Among the most important properties are chemical properties and mechanical properties of materials, both of which play a significant role in determining the suitability of materials for specific applications.

This article dives deep into these properties, explains the Ashby chart and its use in material selection, and discusses how these factors influence decisions in manufacturing and product development. Whether you're an engineer, a designer, or someone new to material science, this article will provide you with valuable insights.

What Are Chemical Properties?

Chemical properties refer to how a material interacts with its environment and how it can change when exposed to various chemicals or conditions. These properties determine the material’s resistance to corrosion, oxidation, and other chemical processes, which is essential in ensuring the longevity and durability of a product.

In simple terms, chemical properties of materials give us insights into how a material behaves under various environmental factors, such as exposure to heat, moisture, or chemicals. For example, stainless steel is chosen for its chemical resistance to rust and corrosion, making it ideal for use in marine environments.

Key Chemical Properties to Consider

- Corrosion Resistance: The ability of a material to withstand chemical reactions, such as rusting or oxidation, when exposed to moisture or harsh chemicals.

- Reactivity: This refers to the tendency of a material to undergo chemical changes when in contact with other substances, like acids or bases.

- Oxidation Resistance: Some materials, like metals, are prone to oxidizing when exposed to air. Materials with high oxidation resistance maintain their structural integrity over time.

- Chemical Stability: The material's ability to maintain its properties without breaking down or reacting when exposed to extreme temperatures, moisture, or chemicals.

How Chemical Properties Impact Material Selection

When selecting materials, especially in industries like aerospace or medical devices, chemical properties can make or break a project. For instance, in the automotive industry, choosing a material with poor chemical resistance could lead to rapid degradation of a car part, increasing maintenance costs and risking safety.

In industries that deal with harsh environments (such as marine or chemical processing), materials with superior chemical properties are required to ensure performance and reliability.

What Are Mechanical Properties?

Mechanical properties describe the behavior of a material when subjected to forces or loads. These properties are crucial in determining how well a material will perform under various physical stresses, such as tension, compression, and shear forces.

Understanding mechanical properties of materials helps engineers select materials that can withstand specific operational conditions without failing or deforming under pressure.

Key Mechanical Properties to Consider

- Tensile Strength: This property refers to the maximum amount of tensile (pulling or stretching) stress a material can withstand without breaking. Materials with high tensile strength are ideal for applications where the material will be subjected to stretching or pulling forces.

- Hardness: Hardness measures a material’s resistance to localized deformation, such as scratches, indentations, or abrasion. It is essential for materials used in cutting tools or those subjected to wear and tear.

- Ductility: Ductility refers to a material's ability to deform under tensile stress, often stretching without breaking. It is crucial for materials used in forming and shaping processes, such as metal forging.

- Elasticity: This property measures a material's ability to return to its original shape after being stretched or compressed. Materials with high elasticity are used in applications like springs and rubber bands.

- Impact Resistance: The ability of a material to resist sudden or shock loading, which is especially important in automotive and safety equipment applications.

How Mechanical Properties Impact Material Selection

The mechanical properties of a material directly influence its ability to perform under stress, heat, or movement. For example, materials used in structural components (like beams, bridges, or buildings) must have high tensile strength and hardness to withstand heavy loads and external forces.

Similarly, in industries like robotics or aerospace, materials with a combination of high tensile strength and low weight are preferred for optimal performance and efficiency.

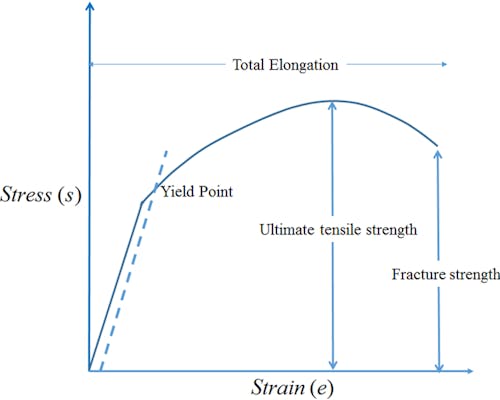

The Stress-Strain Diagram

The stress-strain curve is a fundamental concept in materials science, offering a detailed insight into how a material behaves under stress. This graph plots stress (force per unit area) against strain (relative deformation), helping to characterize a material's mechanical properties and its ability to withstand force.

Here’s a breakdown of the key sections of the stress-strain curve:

- Elastic Region: In the initial phase, the material behaves elastically. Stress and strain are proportional in this region, and the material returns to its original shape once the stress is removed. The slope of this portion of the curve is known as the Young’s Modulus, which indicates the material’s stiffness.

- Yield Point: The yield point marks the transition from elastic to plastic behavior. Beyond this point, the material begins to experience permanent deformation, meaning it won’t return to its original shape when the stress is removed.

- Ultimate Tensile Strength (UTS): This is the maximum amount of stress the material can endure before it starts to fail. The UTS is the highest point on the curve and represents the material’s peak strength before necking begins, where the material's cross-sectional area starts to shrink.

- Fracture Strength: Following the ultimate tensile strength, the material enters a stage where it begins to weaken and eventually breaks. The fracture strength is the point where the material finally fails and breaks apart.

- Total Elongation: On the horizontal axis, total elongation represents the material’s overall change in length from the initial stage to the point of fracture, providing an indication of how much deformation the material can withstand before failure.

This curve serves as an invaluable tool for engineers and materials scientists, enabling them to assess the mechanical behavior of materials and choose the best material for specific applications based on its stress-strain characteristics.

The Ashby Chart: A Visual Guide to Material Selection

The Ashby chart, named after material scientist Michael Ashby, is a powerful tool used by engineers and material scientists to visualize and compare the properties of different materials. It helps identify the trade-offs between chemical properties and mechanical properties and supports decision-making when choosing materials for specific applications.

The Ashby chart typically plots key material properties such as strength, weight, cost, and thermal conductivity, allowing for quick comparisons of different material types.

How to Read an Ashby Chart

The Ashby chart is usually divided into several sections, each corresponding to a specific material property. These properties are represented on the X and Y axes. For instance, the X-axis could represent density, and the Y-axis could represent strength. By looking at the chart, engineers can quickly compare materials that might be suitable for a specific project.

Example of what the Ashby chart might display:

- Strength vs. Density: Helps compare materials based on their strength-to-weight ratio, which is crucial for applications like aircraft and automotive design.

Ashby chart is a powerful tool used for comparing materials based on their strength and density. It helps engineers and designers select the best materials for specific applications, particularly when balancing the trade-off between strength and weight.

- Strength (Y-axis): Represents how well a material can resist deformation under stress, measured in megapascals (MPa).

- Density (X-axis): Shows the mass per unit volume of a material, measured in megagrams per cubic meter (Mg/m³).

Materials are grouped into categories such as:

- Engineering ceramics: High strength and low density, ideal for high-performance uses.

- Engineering composites: Materials combining different substances to achieve high strength-to-weight ratios.

- Engineering alloys: Metals and alloys known for their excellent strength but generally higher density.

- Polymer foams: Lightweight materials with moderate strength, useful in applications where reducing weight is critical.

- Woods: Moderate strength and low density, commonly used in construction and furniture.

- Elastomers: Flexible materials with moderate strength, such as rubber.

The chart also includes diagonal lines representing specific strength (P = 3, 10, 30, 100), which show the strength-to-density ratio. Materials above these lines have both high strength and low weight, making them ideal for applications like aerospace, where performance and lightweight properties are essential.

By analyzing the chart, engineers can make informed decisions on material selection, ensuring the chosen material fits the specific demands of the project, whether that’s minimizing weight, maximizing strength, or balancing both.

Applications of the Ashby Chart

The Ashby chart is invaluable in making quick, data-driven decisions when selecting materials. Engineers use the chart to compare the performance of materials in different areas, such as cost, weight, strength, and durability. This visual comparison makes it easier to identify the best material for a given application.

For example, when selecting materials for a lightweight, high-strength component, the Ashby chart can help engineers visualize the materials that offer the best trade-offs between weight and strength. This approach helps ensure that the right material is chosen based on specific performance criteria.

Integrating Chemical and Mechanical Properties for Optimal Material Selection

When selecting materials, it’s not enough to look at chemical or mechanical properties in isolation. Both sets of properties need to be considered together to ensure that the chosen material meets all performance requirements.

Example: Medical Devices

In the case of medical devices, both chemical and mechanical properties of materials are vital. The material must be chemically stable and biocompatible to avoid adverse reactions with the body. At the same time, it must have adequate mechanical properties (such as tensile strength and elasticity) to withstand physical stress and maintain functionality over time.

Trade-Offs in Material Selection

Sometimes, prioritizing one set of properties over another is necessary. For instance, chemical resistance may be more critical than mechanical strength in a component that will be exposed to harsh chemicals but not subjected to high physical stress.

In other cases, mechanical strength may outweigh chemical properties in applications such as structural engineering, where a material’s load-bearing capacity is the most crucial factor.

Using Chemical and Mechanical Properties, and the Ashby Chart in Manufacturing Processes

In industries such as CNC machining, 3D printing, and injection molding, understanding chemical properties, mechanical properties, and utilizing the Ashby chart can significantly impact the choice of materials, leading to better-performing products and more efficient manufacturing processes.

CNC Machining and Material Selection

CNC machining services involve cutting and shaping materials to create precise components. The mechanical properties of the material are of utmost importance because the components will undergo machining processes that may subject them to stresses like compression and tension.

- Tensile strength and hardness are essential to ensure that the material can withstand the forces exerted during machining without breaking or deforming.

- Materials that are ductile and elastic may be more suitable for components that need to maintain their shape after machining.

The Ashby chart is particularly useful for identifying CNC machining materials with the right combination of strength, weight, and machinability. For instance, materials like aluminum and stainless steel are often selected for CNC machining based on their balance of mechanical properties and workability.

3D Printing and Material Selection

In 3D printing services, selecting materials with the right mechanical properties is essential for ensuring that printed parts are durable and perform as expected in real-world applications. Since 3D printing often uses thermoplastics and metal powders, the chemical properties also play a critical role in the material’s ability to withstand heat and exposure to chemicals.

- Hardness and impact resistance are crucial for parts that will face wear and tear.

- Chemical stability is key when the material is used in environments that might involve exposure to harsh chemicals or extreme temperatures.

The Ashby chart helps engineers quickly identify 3D printing materials with the right properties for specific applications, ensuring that the chosen material can meet both strength and environmental demands.

Injection Molding and Material Selection

Injection molding services are widely used for producing high volumes of parts. The material selected for this process must have high tensile strength, low shrinkage, and good flowability to ensure that the mold can be filled without defects.

- Ductility and elasticity are critical for materials that need to deform slightly without breaking.

- Corrosion resistance is essential for parts that will be exposed to moisture or harsh chemicals over time.

The Ashby chart can help identify the right injection moulding materials by comparing various plastics and metals based on their ability to meet mechanical and chemical requirements for the molding process.

Looking to Optimize Material Selection for CNC Machining, 3D Printing, or Injection Molding? Geomiq Can Help

Selecting the right material is more than a technical requirement; it’s a strategic advantage. Whether you're aiming to enhance durability, reduce production costs, or improve product performance, understanding chemical and mechanical properties is key. Tools like the Ashby chart make it easier to visualize trade-offs and choose the ideal material for your specific manufacturing process.

From lightweight polymers for 3D printing to heat-resistant alloys for CNC machining, every application demands a unique combination of properties. Geomiq’s platform connects you with expert resources and a trusted network of suppliers, helping you make smarter material decisions-faster. Let us help you unlock better performance and more efficient production through informed material selection.

About the author

Sam Al-Mukhtar

Mechanical Engineer, Founder and CEO of Geomiq

Mechanical Engineer, Founder and CEO of Geomiq, an online manufacturing platform for CNC Machining, 3D Printing, Injection Moulding and Sheet Metal fabrication. Our mission is to automate custom manufacturing, to deliver industry-leading service levels that enable engineers to innovate faster.