Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

We offer outstanding 3D printing services in Plymouth, utilizing advanced technologies like SLA, SLS, FDM, MJF, and DMLS. With delivery times as quick as three days, our dependable solutions guarantee precise and accurate parts from the very first print.

All uploads are secure and confidential.

Trusted by

At Geomiq, we specialize in cutting-edge prototyping, end-use, and industrial 3D printing services in Plymouth, designed to meet both small-scale and batch production needs. With access to a global network of more than 350 3D printers, we deliver outstanding quality at competitive rates, solidifying our reputation as a leading 3D printing provider in Plymouth.

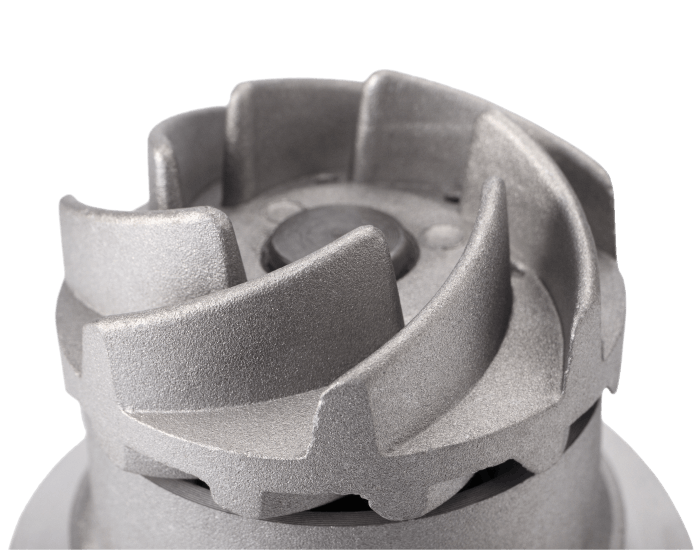

Our metal 3D printing, utilizing DMLS and SLM technologies, is ideal for producing complex parts in materials like Stainless Steel 316L, Aluminium AlSi10Mg, Inconel 718, and Titanium Ti6AI4V.

SLS 3D printing is perfect for industrial applications requiring cost efficiency. We offer materials such as high-performance Nylon PA11, PA12, PP, and TPU, including glass-filled options for added durability.

Our MJF 3D printing service utilizes high-performance materials such as PA11, PA12, and TPU, providing durable and reliable mechanical performance for your parts.

FDM 3D printing offers a cost-effective option with quick turnaround times, making it ideal for creating prototypes, tools, and jigs using durable materials such as ABS, PC, and ULTEM.

Our SLA 3D printing service in Plymouth delivers exceptional detail, making it ideal for visual prototypes, molds, and form-fit checks. We offer materials like ABS-like, PC-like, and Silicone in various colors.

We guarantee quick turnaround and quality results. Order 3D printing services in Plymouth today and receive your parts in as little as three days!

Receive your 3D printed parts in Plymouth in as little as three days while maintaining top-tier quality.

Our cutting-edge technologies enable the creation of parts with intricate designs, and we can accommodate tighter tolerances upon request.

Our 3D printing services produce highly durable parts, suitable for both prototypes and end-use applications.

With experience across aerospace, defense, medical, automotive, and other sectors, we ensure exceptional service for all industries.

We source high-quality 3D printing materials from trusted suppliers, offering a wide range of plastics and metals such as PA2200 and PA12.

Upload your CAD file, specify lead time, and receive a quote specific to 3D printing in Plymouth within 24 hours.

We assign your project to the most suitable manufacturer, locally or globally, and begin production right away.

Our engineers perform thorough inspections throughout the process, ensuring the highest standards.

Our parts are shipped to Plymouth with express services where available, accompanied by inspection reports and delivery notes.

Upload your CAD file, specify lead time, and receive a quote specific to 3D printing in Plymouth within 24 hours.

We assign your project to the most suitable manufacturer, locally or globally, and begin production right away.

Our engineers perform thorough inspections throughout the process, ensuring the highest standards.

Our parts are shipped to Plymouth with express services where available, accompanied by inspection reports and delivery notes.

We prioritize top-tier quality assurance across all stages. Our expert engineers meticulously inspect every detail of your files and parts, from the initial quote to the final product, guaranteeing flawless results on the first attempt.

At Geomiq, we value your time and aim to help you use it efficiently. After you upload your files, we deliver a quote within one business day. Our experienced global partners guarantee that your 3D-printed parts are made to the highest quality, with quick turnaround times.

We work with over 260 trusted 3D manufacturers in Plymouth and globally. This extensive network provides access to top-tier 3D printing capabilities, ensuring exceptional quality and standards from a single access point.

Metal 3D printing (DMLS and SLM)

-

DCTG 6 of DIN EN ISO 8062-3 for dimensions between 0.5 and 30 mm

DCTG 8 of DIN EN ISO 8062-3 for dimensions between 30 and 400 mm

DIN ISO 2768-1 c (coarse) for dimensions between 0.5 mm and 400 mm

Fused Deposition Modelling (FDM)

500mm x500mm x 500mm

± 0.5% with a lower limit of ± 0.5 mm

HP Multi-Jet Fusion (MJF)

370mm x 274mm x 375mm although we suggest 200mm x 200mm x 200mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

PA 12 (MJF): ±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Selective Laser Sintering (SLS)

340mm x 340mm x 605mm although we suggest 320mm x 320mm x 580mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Stereolithograph (SLA)

500mm x500mm x 500mm

Standard ±0,5% (±0,2 mm lower limit)

Industrial ±0,5% (±0,15 mm lower limit)

Metal 3D printing (DMLS and SLM)

-

DCTG 6 of DIN EN ISO 8062-3 for dimensions between 0.5 and 30 mm

DCTG 8 of DIN EN ISO 8062-3 for dimensions between 30 and 400 mm

DIN ISO 2768-1 c (coarse) for dimensions between 0.5 mm and 400 mm

Fused Deposition Modelling (FDM)

500mm x500mm x 500mm

± 0.5% with a lower limit of ± 0.5 mm

HP Multi-Jet Fusion (MJF)

370mm x 274mm x 375mm although we suggest 200mm x 200mm x 200mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

PA 12 (MJF): ±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Selective Laser Sintering (SLS)

340mm x 340mm x 605mm although we suggest 320mm x 320mm x 580mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Stereolithograph (SLA)

500mm x500mm x 500mm

Standard ±0,5% (±0,2 mm lower limit)

Industrial ±0,5% (±0,15 mm lower limit)

Our affordable 3D printing services in Plymouth provide competitive pricing through our AI-powered quoting platform, ensuring you get the best deal.

3D printing allows for quick production of prototypes, enabling you to test and modify designs rapidly.

Create complex designs that are impossible with other manufacturing methods.

3D printing is a more sustainable option, reducing resource consumption through its additive manufacturing process.

3D printing excels in producing intricate and complex shapes that are difficult to manufacture using other methods.

Our on-demand 3D printing services in Plymouth offer the flexibility to produce custom parts as and when needed.

All uploads are secure and confidential.

We utilize an extensive global network of 3D printing service providers, including multiple partners in Plymouth, to deliver top-notch quality, fast turnaround times, and competitive pricing. This broad network provides virtually unlimited capacity, enabling us to efficiently manage large-scale production and complex projects. By strategically routing orders to nearby suppliers, we reduce lead times, lower shipping costs, and minimize the environmental impact of each project. This approach enhances efficiency while supporting more sustainable manufacturing practices.

All of our partners, both in Plymouth and globally, go through a rigorous onboarding process, where we assess their performance in key areas such as on-time delivery, part quality, and cost-effectiveness. We continuously monitor these metrics to ensure that every project is assigned to the best-suited supplier, optimizing production and ensuring seamless delivery based on your specific needs.

Whether you need a one-off prototype or large-scale production, our network’s advanced capabilities ensure that no task is too complex. With the expertise of our partners, we can provide high-precision, custom 3D printed parts in Plymouth that meet your exact requirements, adhere to industry standards, and ensure excellent quality control and customer satisfaction.

See our case studies in action. Discover how we turn ideas into products with our prototyping and manufacturing capabilities.

Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Jamie Fairclough

Design Lead

Industrial Robotics | Arrival

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

James Batstone

Future Product Research Lead

Brompton Bikes

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

Alex Leck

Design Engineer

JCL Lighting

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

All uploads are secure and confidential.