Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Delivering world-class SLA, SLS, FDM, MJF and DMLS 3D Printed parts in as little as 3 days. You’ll receive the perfect 3D printed parts – the first time, every time.

All uploads are secure and confidential.

Trusted by

Geomiq takes on prototype and production 3D Printing and post processing. We can support one-offs or batch production in line with your requirements. With over 350 machines on hand including large format and biocompatible printing, we can bring your 3D printing project to life with ease. We have earned our reputation among the world’s leading companies, working on the very latest 3D printing technologies.

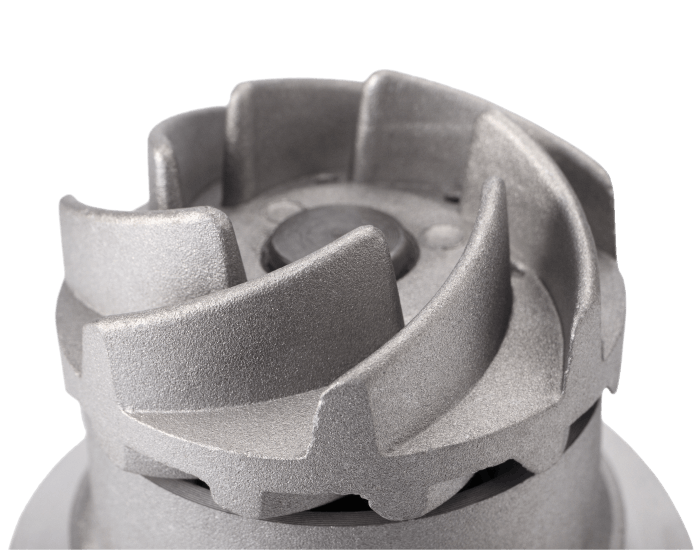

Metal 3D printing DMLS or SLM is best for parts with complex geometry requiring production-grade materials such as Stainless Steel 316L, Aluminium AlSi10Mg, Inconel 718 and Titanium Ti6AI4V.

SLS 3D Printing is popular for inexpensive industrial applications. Offers high performance Nylon materials PA11, PA12, PP and flexible TPU. It also offers glass filled options for further mechanical performance.

HP MJF 3D Printing service offers high performance Nylon materials PA11, PA12, and flexible TPU-95A and Ultrasint TPU offering consistent mechanical performance.

FDM 3D printing offers low cost and fast turnaround functional parts for prototyping, durable manufacturing tools and jigs. A range of rigid plastics including ABS, PC and ULTEM are available.

SLA (Stereolithography) offers unrivalled feature detail and surface quality. Ideal for visual prototypes and models as well as moulds and form and fit checks. Offering ABS-like, PC-like and Silicone in many colours.

Geomiq offers high-quality 3D printing services in the UK. We’re proud to partner with 260+ experienced and highly vetted manufacturers, who have a proven track record of making high-quality, high-precision 3D Printed parts for customers all over the globe. With our partners’ expertise, access to 120+ of the latest 3D printers, our engineers’ attention to detail and our entire team’s commitment to exceptional quality assurance at every stage, you can rest assured that with Geomiq, you’ll receive the perfect 3D Printed parts – the first time, every time.

We’re committed to reducing friction at every stage, so you can be as delighted with the speed of your 3D Printed parts’ arrival as you are with their exceptional quality. Order 3D printing service now to receive your parts in as little as 3 days!

All of our partners’ 3D Printing technologies allow you to produce 3D printed parts with virtually any geometry, and our tolerances are typically +/- 0.127mm.

3D Printing produces durable and impact-resistant parts that are suitable for a multitude of prototype testing or end-use applications, and ready to delight.

From aerospace and energy products to electronics and automotive goods, we’re proud to deliver immaculate 3D Printed parts for any and every industry.

We only offer the best plastic and metal 3D Printing materials and technologies, and can guarantee that you’ll be happy with the quality of each part you receive. Expect nothing less than commercial grade materials, such as PA2200, PA12 – and so much more.

Upload your 3D printing CAD to our platform, select your lead time and get an instant or 24hr 3D printing quote.

We select the most suited manufacturer for your 3D printing order, with production starting immediately.

We are committed to offering the best quality assurance in the business. Our highly skilled engineers triple-check all your files and parts, from the initial 3D printing quote to the final inspection, ensuring your satisfaction the first time, every time.

We ship your 3D printed parts on express services where possible, including physical delivery notes and inspection reports.

Upload your 3D printing CAD to our platform, select your lead time and get an instant or 24hr 3D printing quote.

We select the most suited manufacturer for your 3D printing order, with production starting immediately.

We are committed to offering the best quality assurance in the business. Our highly skilled engineers triple-check all your files and parts, from the initial 3D printing quote to the final inspection, ensuring your satisfaction the first time, every time.

We ship your 3D printed parts on express services where possible, including physical delivery notes and inspection reports.

We are committed to offering the best quality assurance in the business. Our highly skilled engineers triple-check all your files and parts, from the initial 3D printing quote to the final inspection, ensuring your satisfaction the first time, every time.

At Geomiq, we understand the value of your time, and we are dedicated to helping you save more of it. Upon uploading your files, we provide a quote within one business day, and our network of highly experienced partners ensures that your 3D Printing parts are of the highest quality with short lead times.

We collaborate with 260+ experienced and vetted manufacturers. This allows you to access a world-class supply chain, offering great 3D printing capabilities and the highest standards globally, all from a single access point.

Metal 3D printing (DMLS and SLM)

-

DCTG 6 of DIN EN ISO 8062-3 for dimensions between 0.5 and 30 mm

DCTG 8 of DIN EN ISO 8062-3 for dimensions between 30 and 400 mm

DIN ISO 2768-1 c (coarse) for dimensions between 0.5 mm and 400 mm

Fused Deposition Modelling (FDM)

500mm x500mm x 500mm

± 0.5% with a lower limit of ± 0.5 mm

HP Multi-Jet Fusion (MJF)

370mm x 274mm x 375mm although we suggest 200mm x 200mm x 200mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

PA 12 (MJF): ±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Selective Laser Sintering (SLS)

340mm x 340mm x 605mm although we suggest 320mm x 320mm x 580mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Stereolithograph (SLA)

500mm x500mm x 500mm

Standard ±0,5% (±0,2 mm lower limit)

Industrial ±0,5% (±0,15 mm lower limit)

Metal 3D printing (DMLS and SLM)

-

DCTG 6 of DIN EN ISO 8062-3 for dimensions between 0.5 and 30 mm

DCTG 8 of DIN EN ISO 8062-3 for dimensions between 30 and 400 mm

DIN ISO 2768-1 c (coarse) for dimensions between 0.5 mm and 400 mm

Fused Deposition Modelling (FDM)

500mm x500mm x 500mm

± 0.5% with a lower limit of ± 0.5 mm

HP Multi-Jet Fusion (MJF)

370mm x 274mm x 375mm although we suggest 200mm x 200mm x 200mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

PA 12 (MJF): ±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Selective Laser Sintering (SLS)

340mm x 340mm x 605mm although we suggest 320mm x 320mm x 580mm to prevent warping, distortion and inaccuracy.

(Larger parts can be made as multiple sub-parts in and mechanically or chemically joined together)

±0.3% (with a lower limit of ±0.3 mm) although tolerances may change based on part geometry.

Stereolithograph (SLA)

500mm x500mm x 500mm

Standard ±0,5% (±0,2 mm lower limit)

Industrial ±0,5% (±0,15 mm lower limit)

Use our affordable 3D printing services to reduce costs through material efficiency. Cheaper than other manufacturing capabilities

3D printing is a really efficient way to create prototypes. It is quick to iterate and bring modifications

3D printing offers many design possibilities, which can't be manufactured with other technologies

Reduce resource requirements like materials or energy. 3D Printing is a more sustainable option.

3D printing offers the possibility to have complex shapes which will be harder to produce with other manufacturing processes.

3D printing offers this flexibility of on-demand manufacturing. Get custom parts without large inventories.

All uploads are secure and confidential.

We have hundreds of global manufacturing partners for 3D printing services that ensures we are highly competitive and have unlimited capacity. We can route jobs geographically to reduce lead times and shipping costs as well as reducing the carbon footprint of each order. All of our 3D printing partners have stringent onboarding and we use data to track on-time deliveries, quality and pricing. This ensures your job is always with the most suited manufacturing to deliver high-quality and custom 3D printed parts.

See our case studies in action. Discover how we turn ideas into products with our prototyping and manufacturing capabilities.

Oz Andrews

Director

Tyba Home

We use the Geomiq platform as it is the easiest and fastest way to get any of our parts made. They are the obvious choice, highly recommended!

Jamie Fairclough

Design Lead

Industrial Robotics | Arrival

Geomiq streamlines your parts supply chain down to a single supplier. A true enabler for anyone involved with fast paced R&D through to production.

James Batstone

Future Product Research Lead

Brompton Bikes

Geomiq have been fantastic in getting one-off prototype parts to us in our research team super fast so we can go out and test these ideas in the real world using the Brompton Future Lab initiative.

Alex Leck

Design Engineer

JCL Lighting

The quality and service since using Geomiq has rapidly accelerated our development process for roadmap, strategic and bespoke projects.

All uploads are secure and confidential.