THE LEADING DIGITAL MANUFACTURING PLATFORM.

Why do leading brands choose Geomiq to source their parts? Because there's always a supplier somewhere who can produce it faster or cheaper without compromising on quality.

Uploads secure & confidential

TRUSTED BY ENGINEERS FROM LEADING BRANDS

CAPABILITIES

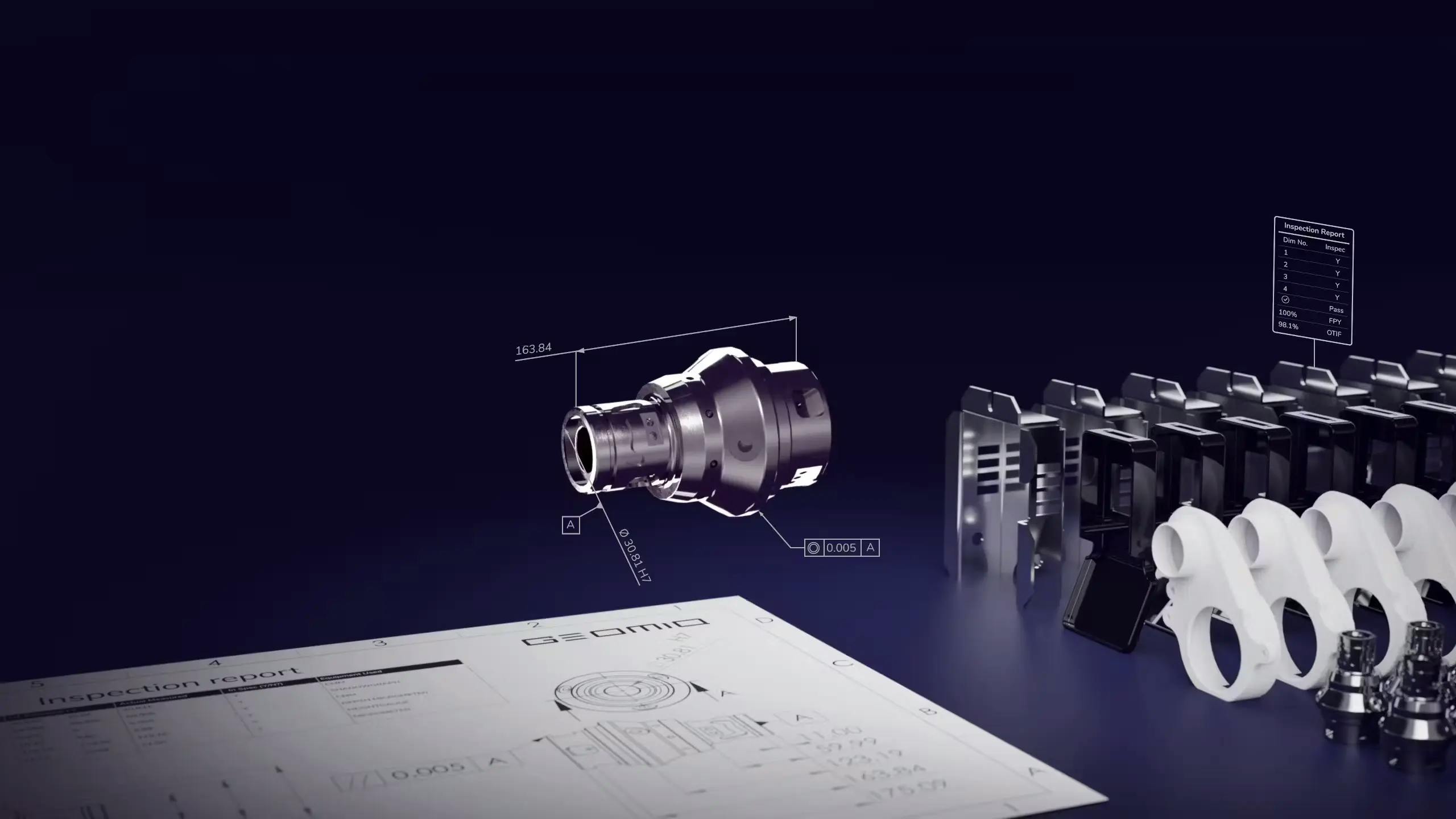

CNC Machining

Order high-quality precision CNC machined parts from a network of experienced global manufacturers capable of hitting tolerances as tight as +/- 0.002mm. Choose from over 30 metal and plastic materials and finishes.

Injection Moulding

Whether you’re after low volume or serial production moulding, our experts in rapid tooling, family moulds, multi-cavity moulds or overmoulding will ensure your samples are ready in days.

3D Printing

From FDM, SLA, SLS and MJF to DMLS printing, we’ve got you covered. Parts can typically be shipped in as little as 3 day, allowing for faster design iterations and speed to market.

Sheet Metal Fabrication

High-quality laser cutting, bending and post-processing in days. Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion-resistance.

How Geomiq Works

Upload + Quote

We source three quotes from matched trusted partners before sending you the best price

Manufacture

Start manufacturing the same day and track live production progress.

Quality + Inspection

We inspect all parts before they arrive with you as well as offering CMM, FAIR, RoHS, Mill Certs.

Delivery

Once approved, we ship on next day insured delivery. Right first time, on time.

CONNECTING AMBITIOUS ENGINEERS WITH A NETWORK OF EXPERIENCED, HARD-WORKING AND HIGHLY VETTED MANUFACTURERS FROM ALL OVER THE GLOBE

All of our 350+ global and local partners are highly experienced, thoroughly vetted and 100% Geomiq approved.

Whether you’re looking for injection moulds, rapid prototypes or large quantities of specialist precision parts, you can trust that we’ll connect you with the right manufacturer for the job.

Our partners’ expertise - combined with the power of our data-driven software and the 1400+ machines on our network - ensures your parts are affordably quoted, quickly delivered and made right the first time, every time.

Why choose Geomiq

Quality assurance at every stage

Find out moreFrom prototype to production in days

Upload your partsLeverage the expertise of our global partner network

Get a quoteJoin us on the path to better,

faster and stronger innovation

Upload your parts to get started